CyTec Systems UK Limited have been appointed as distributors for Ermanno Balzi products in the UK and Ireland.

Ermanno Balzi have developed a rapid plug an unplug systems for cooling circuits on mould tools. A complete range of baffles and plugs is offered.

Ermanno Balzi have also developed innovative products for 2 stage ejection and dynamic gas venting systems, as well as the “Ecovent” systems for cavity venting.

Dynamic Gas Venting

Dynamic venting valves are an alternative venting solution developed by Ermanno Balzi. Correct venting of a mould tool is important as it allows gas and air to escape quickly and helps the plastic to inject faster and at lower injection pressures. This reduces stress and speeds up cycle times.

Standard mould venting involves machining vents between the mould’s mechanical elements e.g. between the parting lines, ejector pins or sliding elements such as slides or cams. When parting lines and sliding elements don’t allow enough venting, the mould cavity can be divided into inserts to increase venting areas.

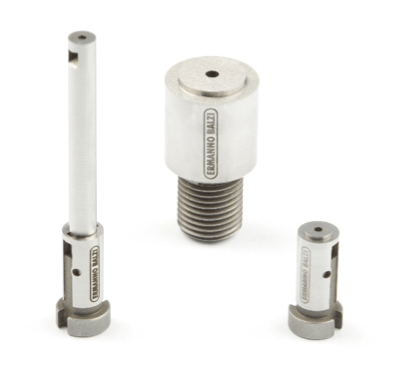

The SGD series is an internal dynamic mould venting valve that is placed into the cavity. An internal dynamic mould venting valve uses a mechanical system that allows the gas to escape from a venting hole that automatically closes under the pressure of the plastic. This valve can be placed inside the cavity where the filling pattern produces gas traps, at last filling point or at runner side. The venting hole has a surface of a few square millimetres, so mould deposits cannot plug it up. Thanks to its high-venting capacity, counter pressure of the air inside the cavity dramatically decreases, which allows a larger window for injection parameters.

The design of the valve requires the sliding shaft to stick into the cavity while in open position. This guarantees open venting channels. The valve is made by an outer sleeve and a central shaft. The shaft can move up and down for a defined stroke. System stroke can be shorter to suit plastic part wall thickness. The shorter the stroke, the longer the plastic protrusion “N”.

The shaft stroke can affect the filling pattern of the cavity. The thinner the plastic part, the shorter the stroke should be. Part thickness and aesthetic requirements determine valve size. Internal dynamic mould venting valve can have a minimum 4mm diameter in the cavity.

Ejector Pins

A further innovation is the fitting of the SGD valve to ejector pins. These are available in a variety of sizes and can be cut to length by the customer. They provide a quick and easy option to provide greater venting to the cavity. They are easily disassembled to allow for cleaning.

For further information, contact CyTec Systems UK on 0161 678 7090.