Wittmann UK’s MacroPower Expands Stechford Mouldings’ Capacity

|

Getting your Trinity Audio player ready...

|

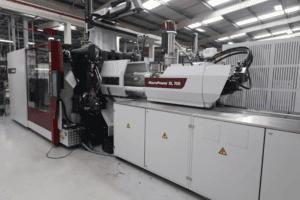

Wittmann UK continues to make inroads into the UK’s large injection moulding machine (IMM) market. Stechford Mouldings (SM) has purchased and commissioned a Wittmann 700 tonne MacroPower package, including temperature control, robotics and conveying systems.

West Midlands-based Stechford will initially use the new MacroPower to supply a growing orderbook in the UK’s automotive supply chain, which currently shows some encouraging signs of growth. The new MacroPower considerably raises Stechford’s capacity for larger thermoplastic components and shot weights and sizes.

Wittmann UK Joint MD Daniel Williams says, “Naturally, we are delighted to have won this important business through competitive tender. We are also greatly encouraged to see that the UK moulding sector continues to opt for all the machine design innovations that we value and supply, namely: a very compact footprint with a large platen area, a turnkey supply of all related ancillary equipment, 4.0 connectivity and – not least – a very competitive price point with extremely low running costs.”

Stechford Mouldings Managing Director Adrian Bridges says that “it says something perhaps that the new Wittmann MacroPower 700 tonner takes pride of place right at the front of our moulding shop. From start to finish, we have been satisfied with all aspects of the MacroPower purchasing process through Dan and his colleagues. Production of these new automotive parts has been seamless and – with our increasing capacity for large mouldings – we look forward to utilising the machine with many new options and orders.”

Throughout its 100-year manufacturing history, Stechford Mouldings has steadily built up an unrivalled fleet of injection, compression and injection compression moulding machines. To those in the know, Stechford has an unrivalled ability in the design and production of thermoset mouldings, which, in many areas, are currently enjoying a revival for their high-quality finish and ‘retro’ design appeal.

The company currently boasts 13 thermoset and injection compression moulding machines (shot weights from 0.1 to 1kg) and 24 compression presses (shot weights to 10kg). For thermoplastic injection technology, the Wittmann MacroPower now joins a total of 24 other injection moulding presses with locking forces from 35- 720 tonnes.

Stechford prides itself on bespoke manufacturing to suit any application. The business has invested heavily in all manner of production equipment, including all the latest 3D CAD/CAM modelling software from Vero VISI CAD; the creation of sample components and prototypes, CMM machines and a fully resourced quality support team.

Over the past nine years, Stechford has turned its 4.7-acre site into a multi-million-pound state-of-the-art destination for all forms of plastic moulding. The business employs a team of 140 specialists and, in the same vein as Wittmann, is known for its ‘one-stop shop’ success in plastics manufacturing.

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275 777

Website

Email