Labotek Supports Plastipack’s Smart Factory Investment with Tailored Material Handling and Blending Solution

|

Getting your Trinity Audio player ready...

|

Labotek GB, in collaboration with long-term partner Ferlin, has played a key role in helping Plastipack Ltd improve manufacturing efficiency as part of a recent smart factory investment project.

Plastipack, based in St Leonards on Sea, is a leading UK manufacturer of energy-saving bubble cover materials for swimming pools and water storage applications. Supplying bulk roll material to fabricators worldwide, their products are used in both domestic and industrial settings to reduce energy use, save water and minimise operational time. With water conservation now a global priority, Plastipack’s products support efforts to tackle evaporation and reduce environmental impact.

When Plastipack decided to upgrade its material conveying and blending systems, it turned to Labotek GB for a future-proof, cost-effective solution that could be customised to the unique layout of its extrusion equipment. A key requirement was the ability to monitor and control material usage in real time, allowing the operations team to maintain tight control over process efficiency while accommodating the seasonal nature of production.

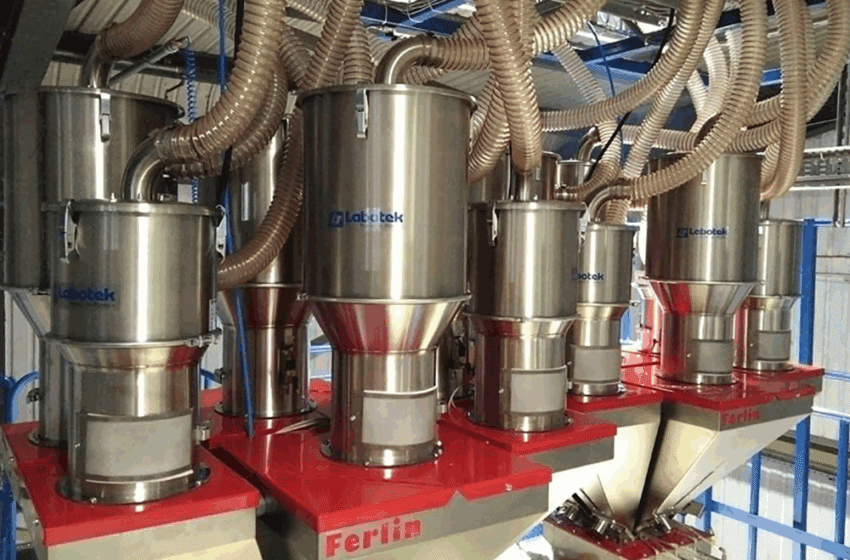

With a working relationship spanning more than ten years, Labotek and Ferlin were well-positioned to support Plastipack’s goals. The project saw the installation of Ferlin’s latest Gravimix dosing system, tailored to the site’s specific layout, alongside the Ferlin Bridge software platform. This powerful combination now provides live insights into hopper activity and detailed remote access to production data, enabling faster decision-making and tighter control of material use.

Since installation, Plastipack has reported significant improvements in process efficiency. More accurate dosing has led to noticeable margin gains, and real-time data has allowed the team to make immediate adjustments and reduce material waste. The successful integration of the system is a direct result of Labotek’s commitment to understanding its customers’ production environment and delivering practical, innovative solutions.

This project forms part of a broader efficiency programme at Plastipack. Other recent initiatives include fitting insulation jackets to extruders to reduce startup times and switching to energy-saving sensor LED lighting across the shop floor and warehouse. The next step will be implementing a full shop floor monitoring system to provide real-time visibility of production and help identify further opportunities to eliminate waste.

Labotek GB is proud to support forward-thinking manufacturers like Plastipack with equipment and expertise that deliver measurable improvements across the production process.

Read more news from Labotek here.

Labotek

+44 (0) 1564 822172

Website

Email