JC3DDesign Blog // Will a 3D Printed Part be Strong Enough for Real World Use?

|

Getting your Trinity Audio player ready...

|

One of the most common questions we get asked is: Will a 3D printed part actually be strong enough for what I need it to do? It’s a fair concern. When people think of 3D printing, they often imagine delicate prototypes or plastic models. But the truth is, modern 3D printing can produce highly durable, functional parts if it’s done right. In this blog, JC3DDesign explores the real-world performance of printed parts, how to address common 3D print strength concerns, and what to consider if your project demands strength, durability or load bearing performance.

Can 3D printed parts really be used for functional applications?

Yes, and they often are. At JC3D Design, we produce parts used in:

- Testing and validation of mechanical systems

- Custom brackets and housings in industrial settings

- Automotive and motorsport applications

- End use parts for small product runs

The key is to match the right material, design and print method to the part’s purpose.

Common strength concerns and how we address them

Let’s break down the typical worries and how we solve them.

Concern 1: “Isn’t it just plastic?”

Yes, most desktop 3D printing is done with plastic based filaments like PLA, PETG or nylon. But not all plastics are created equal.

- PLA is good for rigid models and low stress parts.

- PETG offers flexibility and higher impact resistance.

- ABS can handle heat and stress but requires more care.

- Nylon is tough, abrasion resistant and ideal for functional parts.

At JC3D, we help you choose the right material based on how the part will be used.

Concern 2: “Won’t the part break under load?”

This depends on:

- The material used

- The orientation of the print

- The infill pattern and density

- The design geometry

3D printed parts are strongest in the XY plane (the horizontal layers). Parts printed upright (in the Z direction) are weaker at layer lines. That’s why we optimise print orientation for strength and function, not just speed.

Concern 3: “I’ve seen prints snap or delaminate. What went wrong?”

These failures usually come from poor print setup:

- Too little infill

- Weak layer adhesion

- Incorrect material for the load

- Unsuited part geometry

We’ve seen parts fail from designs meant for injection moulding simply being exported to STL and printed. That rarely works well. We always check if a model needs adjusting for 3D printing to improve its strength and performance.

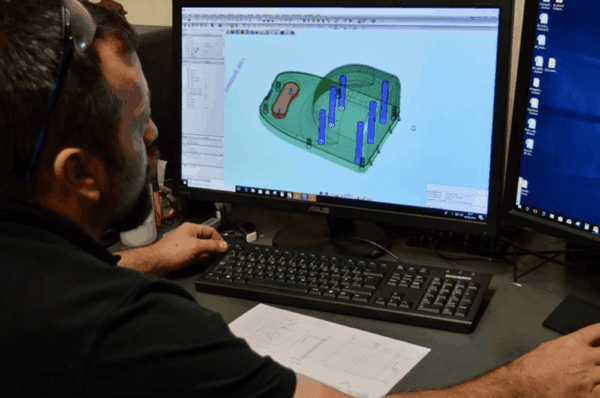

How we design for strength

Designing for 3D print strength is a different mindset. Here’s how we approach it:

- Avoid thin unsupported features – These are the first to fail. We thicken critical load points and round corners to reduce stress.

- Orient for layer strength – Where possible, we orient parts to keep forces across layers, not between them.

- Use mechanical reinforcement – If needed, we include holes or sockets for metal inserts, bolts or fasteners.

- Infill and wall thickness – We increase wall count and choose the right infill pattern and density to match the performance needs.

When is 3D printing not the right choice?

We’ll be honest. If your part needs to:

- Withstand extremely high loads

- Replace machined or forged metal components

- Be safety critical with certification requirements

Then we may recommend a different method or material. For some parts, CNC machining or injection moulding is a better fit.

But for most low to medium duty parts, custom components or single part designs, 3D printing delivers more than enough strength. Especially when designed and printed correctly.

Case study: From prototype to production

A recent client came to us needing a custom sensor mount for a testing rig. The part needed to:

- Support a 1 kg load

- Clamp securely to a metal frame

- Be heat resistant up to 70°C

We printed it in PETG with:

- 50% gyroid infill

- 3 mm walls

- Horizontal print orientation

It performed flawlessly in testing and is now being used in production. No breakages. No failures.

Summary: Can 3D printing deliver strength?

Absolutely. But it depends on:

- The material you choose

- The way the part is designed

- The experience of the person printing it

At JC3D, we do not just print files. We design and print with real world use in mind. If your part needs to take a beating, we’ll tell you honestly whether 3D printing is right for the job and how to get the most from it.

Read more additive manufacturing news here.

JC3DDesign

01733821736

Website

Email