Evolution Cooling Blog // 7 Maintenance Tips to Keep Your Cooling Systems Running Efficiently

|

Getting your Trinity Audio player ready...

|

Chiller maintenance is essential for ensuring the long-term performance and efficiency of your industrial cooling systems. Proper chiller service not only helps to extend the lifespan of your equipment but also ensures energy efficiency and prevents costly downtime. Whether you’re new to chiller maintenance or an experienced professional, these essential tips will help keep your system running at peak performance. In this blog, Evolution Cooling explores seven essential chiller maintenance tips that help maximise cooling efficiency, reduce operational costs, and extend the lifespan of your industrial systems.

1. Regular Cleaning of Condenser Coils for Efficient Heat Transfer

Over time, dirt and debris can accumulate on your chiller’s condenser coils, impairing heat transfer and causing the system to work harder. Regular cleaning of condenser coils is an essential part of chiller maintenance to ensure efficient cooling and to prevent the risk of system failure.

2. Check and Maintain Refrigerant Levels

Low refrigerant levels can cause reduced cooling performance, and if left unchecked, they could lead to compressor damage. Regular refrigerant level checks and leak testing should be a part of your scheduled chiller service. These checks will help maintain optimal cooling efficiency and system reliability.

3. Air Filter Inspection and Cleaning

The air filters in your chiller help prevent dust and contaminants from entering sensitive components. Regularly inspecting and cleaning these filters is a simple yet effective maintenance task that ensures your chiller operates smoothly without obstructed airflow.

The Delta T (temperature difference between the supply and return water) is an important performance indicator for chillers. A significant change in this temperature can suggest issues with the chiller’s operation. Regularly monitor the Delta T during routine chiller maintenance to ensure the system is functioning efficiently.

5. Lubricate Moving Components

Proper lubrication of moving components such as fans, pumps, and motors helps to reduce friction, prevent wear, and ensure the smooth operation of your chiller. Incorporating this step into your regular chiller service can extend the life of these vital components.

6. Monitor Pressure Levels for Early Fault Detection

Maintaining the correct pressure levels in your chiller system is critical for avoiding problems like compressor failure or blockages. Keep a close watch on both the evaporator and condenser pressures, as significant changes may indicate a need for service or repairs. Early detection through routine maintenance can save you from costly downtime.

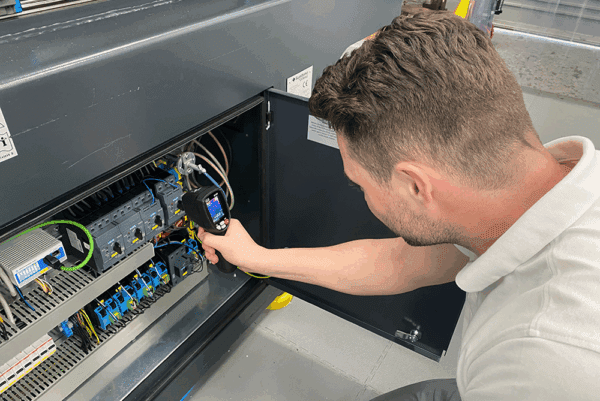

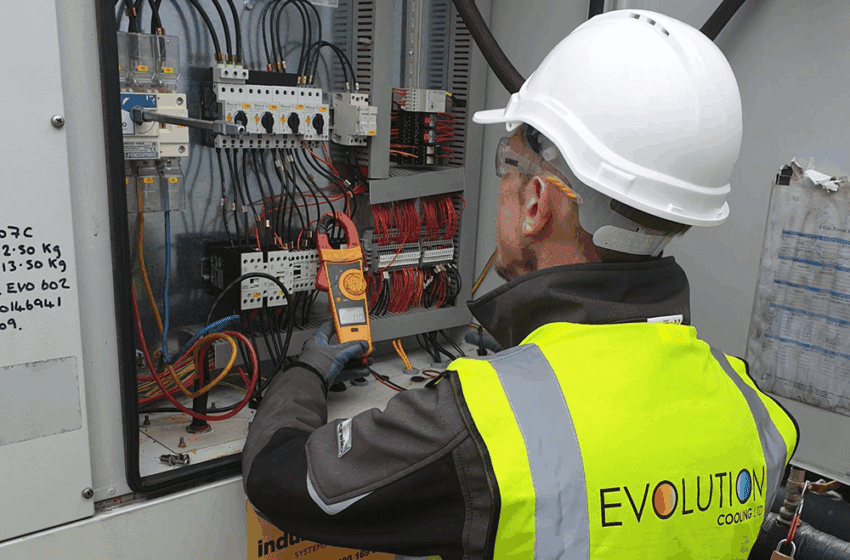

7. Schedule Professional Chiller Service Regularly

While routine maintenance can be done in-house, scheduling professional chiller service is crucial to identify any issues that might not be visible during basic inspections. Expert technicians can carry out thorough diagnostics and ensure all components of your chiller are functioning optimally. Regular servicing will help you avoid unexpected repairs and maintain system efficiency.

Conclusion

Chiller maintenance is crucial to the performance and longevity of your cooling systems. By following these tips and scheduling regular chiller service, you can enhance energy efficiency, reduce downtime, and extend the life of your equipment.

Read more news from Evolution Cooling here.

Evolution Cooling

0121 820 8946

Website

Email