Micro Systems Driving Medical Innovation with High Performance Micro Moulding

|

Getting your Trinity Audio player ready...

|

The advancement of next-generation medical devices, miniaturised diagnostics, implantable sensors, and ultra-compact delivery systems demands precision manufacturing to meet regulatory and functional requirements. Precision micro moulding offers unparalleled capability to produce such components with extremely tight tolerances and complex features. UK-based Micro Systems has developed industry-leading solutions to turn these device concepts into validated, high-performance products.

What is precision Micro Moulding and why does it matter?

Precision micro moulding refers to injection moulding with shot weights in the milligram range, and features measuring from 50 μm down to 5 μm or less, with tolerances as fine as ±0.001 mm. This process allows for the creation of ultra-small, high-complexity parts, crucial for microfluidic lab-on-a-chip components, micro-nozzles, and implantable elements.

Key benefits:

- Superior surface finish and precision, even at sub-micron scale.

- Reduced material waste due to small-shot systems and efficient runner designs.

- Potential cost efficiencies compared to standard tooling due to smaller clamps and shorter cycles.

How Micro Moulding benefits the future of complex Medical Devices

The next generation of medical devices is becoming increasingly complex, multifunctional, and miniaturised. Future medical systems, from implantable drug-eluting implants to combination products with integrated microfluidics, demand manufacturing methods that can meet stringent tolerances and enable novel design approaches. Micro moulding provides several critical benefits for such devices:

1. Miniaturisation without compromising functionality:

Complex assemblies can be consolidated into a single moulded component, reducing the need for manual assembly and lowering the risk of human error.

2. Integration of active features:

Features such as micro channels, optical surfaces, snap-fit mechanisms and micro-threads can be moulded directly, supporting the trend towards integrated, smart medical systems.

3. Precision for combination and drug delivery devices:

Drug delivery platforms, such as next-generation auto-injectors and on-body delivery systems, require precise metering, sealing and alignment. Micro moulding ensures consistent dosing mechanisms and reliable actuation over millions of cycles.

4. Material compatibility with advanced polymers:

High-performance polymers like PEEK, COC and bioresorbable materials can be micro moulded to meet biocompatibility, sterilisation and mechanical requirements for complex implants and diagnostic devices.

5. Scalability for mass production:

Once validated, micro moulding allows complex components to be manufactured in multi-cavity tools with short cycle times, making it highly suitable for high-volume markets such as insulin delivery, minimally invasive surgical tools, and point-of-care testing.

How Micro Systems empowers next-generation Medical Device development

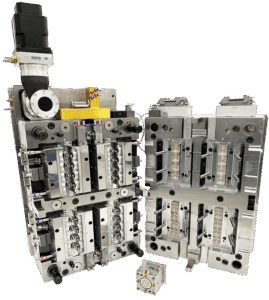

1. Ultra-precision tooling & manufacturing excellence

Micro Systems offers over 20 years of expertise in ultra-precision mould design and manufacture for medical, pharmaceutical, diagnostics, and ophthalmic applications. Their UK and Singapore facilities feature advanced technologies including micro-milling, EDM and micro metrology, achieving tolerances down to ±0.001 mm and surface finishes down to the nanometre level.

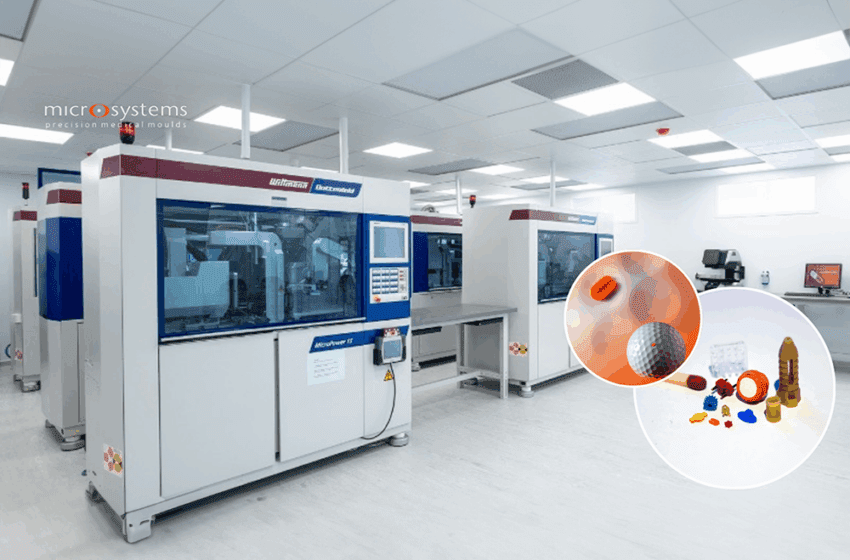

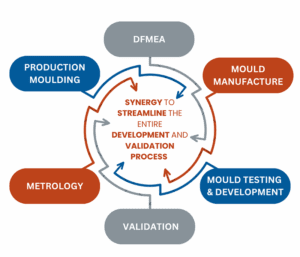

2. End-to-End turnkey production in cleanroom environments

Micro Systems integrates DFM, mould manufacture, testing, metrology, and ISO 13485-validated production under one roof. Their on-site Optimold facility, an ISO Class 7 cleanroom, is equipped for full-scale injection moulding, including two-material overmoulding, from prototypes to mass production.

3. Precision micro moulding for micron-scale features

At their ISO Class 7 micro moulding facility, Micro Systems delivers thin-wall moulding with integrated optical features and tolerances of ±0.001 mm in a cleanroom setting, ensuring extreme precision and consistency across production runs. They manufacture components such as microfluidic chips, PEEK implants, bioresorbable implants, micro-tube connectors, and micro-nozzles.

4. Advanced metrology for rigorous quality assurance

In-house metrology includes CMMs with micron-level tolerance, white-light interferometry, confocal systems, and even CT scanning to ensure sub-micron feature accuracy and nanometre-grade surface measurement. This underpins Micro Systems’ rigorous validation and quality assurance protocols.

5. High-performance material expertise

Micro Systems is experienced in micro moulding medical-grade PEEK, manufacturing intricate implants with features in the micrometre range. Their process ensures controlled crystallinity and thermal stability to maintain mechanical performance and biocompatibility, with production taking place within an ISO Class 7 cleanroom to meet stringent medical standards.

Future outlook: Precision micro moulding in next-generation medical devices

Medical technology is moving towards smaller, smarter, multifunctional devices, and precision micro moulding is a key enabler. Key trends include:

- Advanced miniaturisation: Multi-functional features, fluidics, sensing, actuation, optical paths, can be integrated into single, precise parts, reducing assembly and improving reliability.

- Smart, connected devices: Micro-moulded housings and channels with micron-level tolerances accommodate embedded sensors, electronics, and microfluidics.

- Bioresorbable & high-performance polymers: PEEK, COC, and bioresorbable materials can be shaped precisely while maintaining mechanical performance, sterilisability, and biocompatibility.

- Scalable, customised production: Rapid tooling and flexible multi-cavity configurations support both high-volume and patient-specific devices.

- Integration with smart manufacturing: AI-assisted process control, in-line metrology, and predictive maintenance ensure reproducibility and quality for complex components.

Precision micro moulding is crucial for the next wave of medical devices, offering miniaturisation, functional integration, and regulatory compliance at scale. Micro Systems, with its integrated capabilities and cleanroom infrastructure, stands at the forefront of this movement, enabling OEMs to realise next-generation healthcare innovations faster and with confidence.

Micro Systems will be exhibiting at Medical Technology Ireland on 24th–25th September at Galway Racecourse! Join us at Stand 322 to explore how our precision micro moulding expertise can accelerate your medical device innovation. Whether you’re looking to discuss new projects or explore advanced manufacturing capabilities, we’d love to chat. To book a meeting in advance, email us at info@microsystems.uk.com.

Get more news from Micro Systems here.

Micro Systems

+44(0)1942 290 960

Website

Email