Why More UK Manufacturers Are Reshoring Production in 2025 // BEC Group Blog

|

Getting your Trinity Audio player ready...

|

Business and trade have changed dramatically over the past few years, and manufacturing companies are responding by rethinking their production strategies. What once seemed like an irreversible trend towards offshore manufacturing is now moving in the opposite direction, with more businesses choosing to bring their operations back home. This isn’t just about sentiment or incentives – it’s hard-nosed business logic. Companies are discovering that the cost advantages of overseas production have eroded, whilst the risks have multiplied. In this blog, BEC Group explores reshoring and why businesses are gaining immense advantages from it.

The Factors Driving Reshoring

Several factors are combining to make UK-based production far more attractive than it’s been for decades.

Brexit initially created uncertainty, but it’s also clarified the benefits of domestic production. UK manufacturers no longer face the complex paperwork and potential delays associated with EU-based suppliers, while maintaining straightforward access to their largest markets.

Meanwhile, the new US administration’s tariff policies have made exporting to America more expensive for many overseas manufacturers. Companies producing goods for both the UK and US markets are finding that domestic production often provides the most cost-effective route to both destinations.

It’s no surprise that some 95% of supply chain managers cite resilience as their top priority, an increase from 69% the year before. The BBC reported in 2024 that as many as half of manufacturers are now planning some form of reshoring.

Supply Chain Lessons Learned

In addition to the above, the past few years taught businesses some expensive lessons about putting all their eggs in one basket situated overseas.

Container shortages, port closures, and shipping delays that once seemed like temporary blips became persistent problems affecting entire business cycles.

The True Cost of Distance

With this, smart companies have started calculating the total cost of ownership rather than just comparing unit prices. When you include all the hidden expenses of managing complex international supply chains, domestic production often comes out ahead.

Key cost considerations driving reshoring decisions include:

- Shipping and logistics expenses: Rising fuel costs and container shortages increase transport costs

- Quality control visits: Regular overseas trips for production oversight add up quickly

- Inventory carrying costs: Longer lead times mean more working capital tied up in stock

- Currency hedging: Protecting against exchange rate fluctuations costs money

- Insurance and risk management: International supply chains require more comprehensive coverage

Companies discovered that saving 20% on unit costs meant nothing when shipments arrived three months late, customers cancelled orders, and reputations suffered – a lesson often learned the hard way.

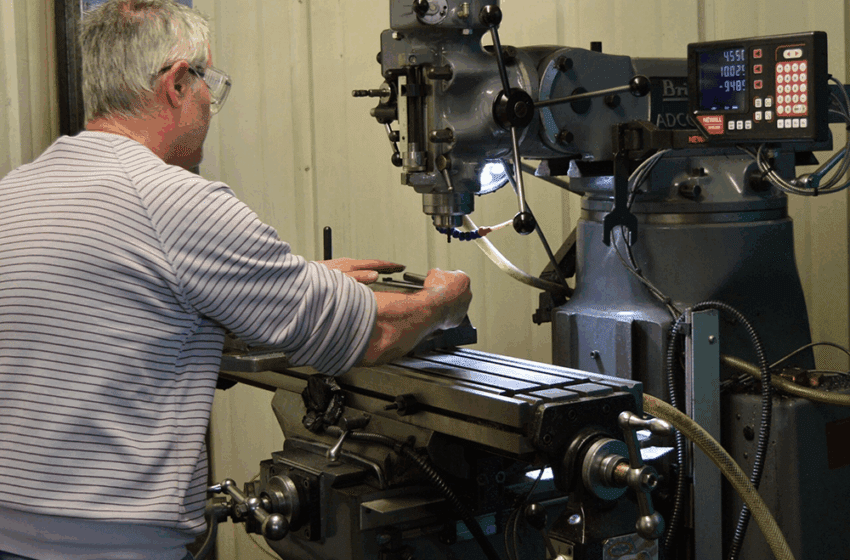

Toolmaker services in the UK can respond to urgent modifications within days rather than weeks. Design changes that might take months to implement overseas can happen in real-time when production is local.

Skills and Innovation Advantages

On a positive note, the UK’s skilled workforce brings advantages that pure cost comparison doesn’t capture.

Experienced manufacturers understand local market requirements, work within regulatory frameworks, and can collaborate with you on every step of the design and production journey.

Ideas that might take months to communicate and implement across borders can be tested and refined in days. We’ve seen that make a decisive difference to some companies.

Reshore With BEC Group

Reshoring’s growth reflects substantial changes in how businesses perceive risk, cost, and competitive advantage.

Companies that once chased the lowest unit price are now prioritising reliability, responsiveness, and total cost of ownership.

At BEC Group, we’re working with businesses across industries to bring their production home successfully. We offer the tooling expertise, manufacturing tech, and collaborative workflows that make reshoring work effectively.

Click here to read the latest news from BEC Group.

BEC Group

+44 (0)1425 613131

Website

Email