Breaking The Mould: Demystifying Lubricants in Plastic Injection Moulding // Millers Oils Blog

|

Getting your Trinity Audio player ready...

|

Did you know that 95% of premature pump failure in an injection moulding machine can be attributed to hydraulic oil.

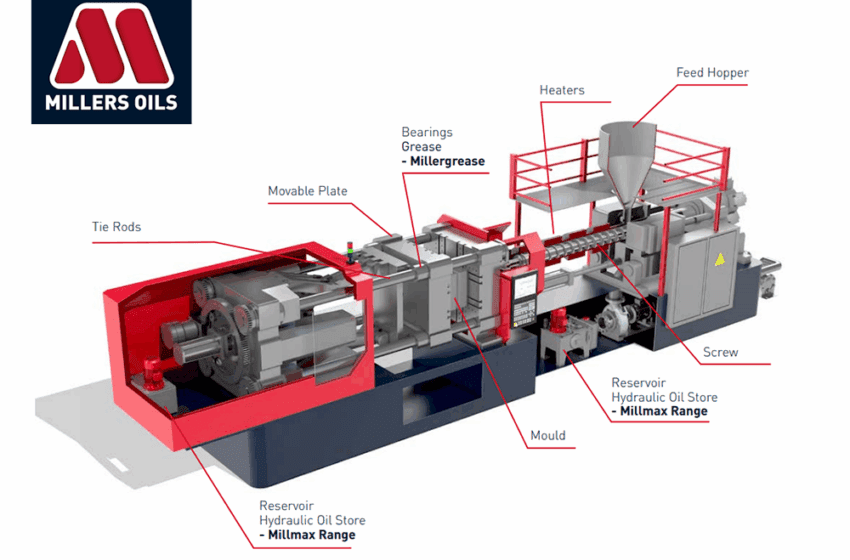

A hydraulic system is used to transmit power through the medium of hydraulic oil and converts fluid power into mechanical power. The oil is stored in the oil tank or reservoir, then pressurised by the hydraulic pump and delivered to an actuator, which converts the fluid’s energy into motion to close the moulds.

Lubricants are used to effectively and efficiently support the high frequency, high load expected in plastic injection moulding machines. Hydraulic oil is often referred to as the lifeline of these machines because it is so integral to the system’s operation. Choosing the right oil for your machine is often the easy part if you have OEM specifications, but understanding lubricant maintenance is key to mitigating some of the challenges within the industry.

Injection Moulding Inefficiencies

With any high-pressure hydraulic system, there are inevitable challenges within the operation of machinery. Some of the most common challenges in plastic injection moulding machines relate to pump wear, rust, and degradation of the hydraulic fluid through oxidation, which can also give rise to sludge formation.

Wear

As the main fluid used in plastic injection moulding, premium hydraulic oils need to provide excellent anti-wear and protection properties due to the high pressure and intense environments. Wear occurs most commonly in the hydraulic pump; however, hydraulic oils with optimised anti-wear chemistry can prolong the life of a pump, saving you expensive replacement costs and downtime.

The Chemistry

Friction modifiers and anti-wear chemistry in the hydraulic fluid work together to form protective films on metal parts, protecting them from abrasive wear and reducing friction to minimise energy losses.

Rust and Oxidation

Rust and oxidation are common issues due to the chemical reactions that degrade materials used in injection moulding machines. Rust forms when iron combines with water and oxygen in the electrochemical process and compromises a machine’s integrity and performance. Corrosion can degrade non-metallic components and depends on factors such as pH levels, lubrication and the material’s composition.

The Chemistry

Rust preventative oils have a dual performance strategy:

- Passive surface exclusion to form a molecular film across a surface, creating a barrier that restricts the ingress of oxidising agents such as oxygen and water.

- A chemical neutralisation where embedded corrosion inhibitors react with iconic contaminants and neutralise acidic species before they can initiate oxidation.

Temperature Fluctuations

Plastic injection moulding machinery can reach high temperature levels due to the speed and frequency of production; additives ensure that the fluid is able to resist the high temperatures meaning the end products aren’t compromised.

The Chemistry

Additives extend the operating rage of oils to higher or lower temperatures without affecting fluidity and causing friction and other issues occurring.

What Makes a Hydraulic Oil High-Performance?

Additives are what gives a lubricant its je ne sais quoi or its special properties. The combination of additives determines how the hydraulic oil performs and how suitable it is for a particular application.

Most conventional hydraulic fluids offer a basic level of performance requirements. However, high-performance hydraulic oils deliver superior operational efficiency, enhanced protection and reliability by maintaining optimal viscosity within the system’s ideal operating window across varying temperature and pressure conditions.

Their advanced formulation reduces internal fluid friction, thereby enhancing mechanical efficiency and minimising energy losses. Additionally, these fluids exhibit significantly extended oxidation stability, particularly under high-speed and high-pressure environments— contributing to longer service life and reduced frequency of oil replacement.

Components of a hydraulic oil vary depending on the formulation of additives. Millers Oils blending expertise is what makes us stand out from the crowd. A typical hydraulic oil may include a combination of additives but our formula is what sets us apart.

Miller’s Oils Fluid Management Division

Our priority at Millers Oils is to keep costly failures and downtime to an absolute minimum for our customers by maintaining the life of the oil before any degradation occurs. Our Fluid Management Service takes a proactive, on-site approach to safeguard your high-value equipment. Using industry-leading filtration technology, we help ensure your systems operate at peak efficiency, extend oil life, reduce drain intervals, and significantly cut operational costs and environmental impact.

Find the full blog from Millers Oils here.

Read more news from Millers Oils here.

Millers Oils

+44 (0)1484 713201

Website

Email