Six New Partners Join PlastikCity in Q3

Since mid-June, six additional companies have become PlastikCity Partners, bringing a range of equipment and services to PlastikCity and its users.

All of these new partners stay true to PlastikCity’s principle of only partnering UK & Ireland-based companies with high-quality equipment and services.

Meet our new Partners:

FIPA is a global specialist in vacuum, gripping and lifting technology with over 40 years of experience in industrial automation. The company provides customised solutions to support efficient, future-proof production processes, maintaining high standards of quality and service. Its extensive product portfolio includes mechanical grippers, vacuum suction cups, standard components, and vacuum tube lifters, all designed to optimise handling and improve manufacturing workflows. FIPA joins PlastikCity in our Vacuum Systems & End Of Arm Tooling categories.

Omega Plastics Group (OPG) provides low to high volume tooling and multi-use injection moulding services, offering complete turnkey solutions from concept to manufacture, assembly, and despatch. The company produces parts from under 1g to 4kg for serial production, batch runs, and prototype builds, using materials such as PP, ABS, PC, Nylon, and various technical, medical, and food-safe grades. Its in-house toolroom features advanced CNC, EDM, and lathe equipment to build tools up to 3T, support offshore projects up to 16T, and deliver full tooling maintenance, diagnostics, repairs, and refurbishments. OPG joins our Injection Moulding, Toolmakers, and Post-Mould & Assembly Services categories.

Opus International Projects specialises in injection moulding and complete product development for high, medium, and low volume production. With a machine range from 30T to 1200T, the company supports sectors including automotive, consumer, industrial, and defence. Opus also offers sub-assembly services, enabling fully integrated manufacturing solutions that combine precision, flexibility, and technical expertise. Opus joins PlastikCity in the Low Volume Injection Moulding and Plastic Product Designers categories.

RP Technologies is a leading UK manufacturer of complex aluminium injection mould tooling, supporting prototype, pre-production, and production volumes of plastic injection moulded components. Operating from its West Midlands facility, the company delivers fast-turnaround tooling for low to medium volume production, combining precision engineering with highly skilled toolmaking expertise. RP Technologies also produces CNC-machined components in a wide range of metals and polymers, working to tight tolerances and supporting every project with ISIR assessments and rigorous quality testing. The company is ISO 9001:2015 certified. RP Technologies joins us in the Low Volume Injection Moulding and Prototyping & Rapid Tooling Services categories.

Strata Products is a leading UK manufacturer of home, office, and garden plastic products, operating from a 320,000 sq. ft. facility in Nottinghamshire. The site runs 24/7 with over 40 injection moulding, blow moulding, and rotational moulding machines, producing a wide range of high-quality and innovative products for UK and global markets. Strata is a major supplier of watering cans, water butts, compost bins, decorative planters, storage boxes, and flexi tubs, and has received multiple industry awards, including the Queen’s Award for Enterprise: International Trade. The company combines extensive in-house product development with advanced manufacturing and distribution capabilities to meet the demands of competitive markets. Strata joins PlastikCity in the Rotational Moulding and Blow Moulding categories.

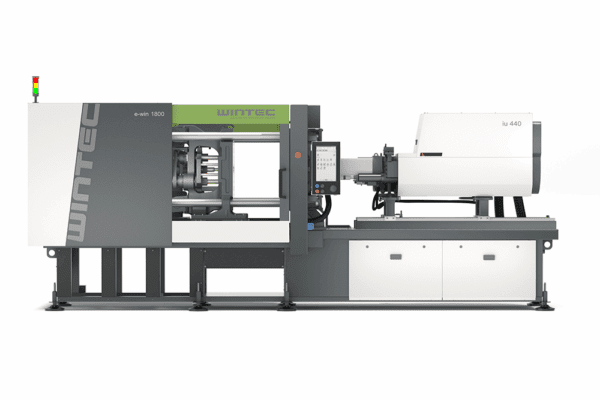

UK-NSI is a leading contract manufacturing services provider, offering precision, quality, and reliability across multiple industries. Operating from a 24,000 m² facility, including 11,000 m² of dedicated manufacturing space, the company delivers high-volume production solutions supported by advanced processes and strict quality control. Specialist capabilities include high-quality PCB assembly, precision injection moulding up to 350T (including cleanroom and optical-grade moulding), system integration, and full end-to-end production. UK-NSI serves sectors such as automotive, industrial, consumer, and medical technology, and holds IATF 16949, ISO 9001, ISO 45001, and ISO 14001 accreditations. UK-NSI joins us in the Injection Moulding and Medical & Cleanroom Injection Moulding categories.

If you’re not already a PlastikCity Partner and you want to promote your company in 2025 and beyond, submit your application form here or contact PlastikCity at info@plastikcity.co.uk or 01455 209270.

PlastikCity

+44 (0) 1455 209270

Website

Email