PlastikCity on Tour – Applied Coating Technologies

|

Getting your Trinity Audio player ready...

|

For the latest stop on our PlastikCity on Tour series, Becca and Will headed to the West Midlands to visit long-time PlastikCity Partner, Applied Coating Technologies (ACT). Based in Oldbury, ACT is a specialist in the application of functional and decorative coatings to plastic components, with a reputation for technical excellence and customer-driven solutions.

We were welcomed by Dominique Williams (Commercial Director), Christine Hancock (Managing Director), and Mujtaba Zaka (Technical Director), who kindly gave us a tour of the facilities and shared the fascinating story behind ACT’s evolution into one of the UK’s leading coating experts.

(Pictured above, left to right, Becca Watt, Christine Hancock, Will Clarke, Dominique Williams and Mujtaba Zaka.)

A Technically Driven Coatings Specialist

Applied Coating Technologies (ACT) was founded in 2000 by Dr Yasin Zaka and Christine Hancock, following the closure of a former coatings business, as the mobile phone market, a huge sector in the UK at the time, shifted its production to China. With deep technical expertise and a desire to build a more flexible, customer-focused operation, the pair launched ACT to specialise in EMI (electromagnetic interference) and RFI (radio frequency interference) shielding coatings for plastic components.

From the outset, ACT’s mission has been to provide superior-quality, technically advanced coating solutions, tailored to the unique needs of each customer. Over the past 25 years, the company has steadily expanded its services and capabilities to become a true one-stop shop for plastic coating requirements across multiple industries.

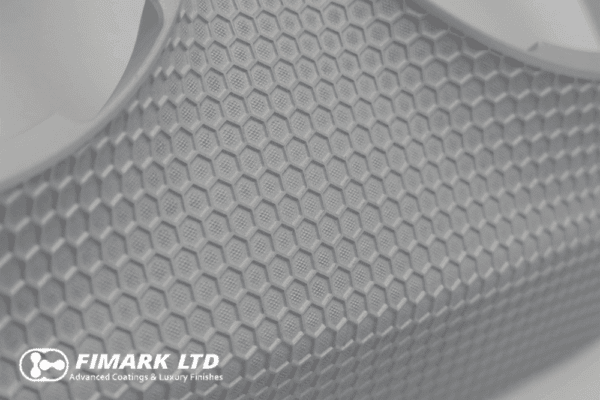

Not a moulder itself, ACT coats the moulded products of its customers with a wide variety of technical and aesthetic coatings, ranging from single-coat applications of paint to more complex two and three-coat finishes. As well as increasing visual appeal with new colours or textures such as high-gloss or matte finishes, the feel, wear resistance and perceived value of a plastic product can be significantly enhanced with a surface coating.

ACT also specialises in functional coatings, which change the properties of moulded components. Typically using bespoke paint dispersions containing Nickel, Copper or Silver particles, ACT applies conductive paints for EMI and RFI shielding, protecting delicate internal components from external interference from electronics and radio signals, and vice versa. Paints can be applied directly to a wide range of technical and engineering polymers, with functional coatings commonly used in the defence, medical, electronics, aerospace and automotive sectors.

ACT now operates from two facilities in Oldbury – Western Road and Tipton Road, each geared towards different production volumes and customer types. The Tipton Road site focuses on high-volume automotive programmes and is home to two fully robotic paint lines designed for interior and exterior trim. Meanwhile, the Western Road site caters to low- and medium-volume projects across sectors such as white goods, electronics, defence, medical, and more. It houses both a robotic paint line and an extensive manual spray facility, offering unmatched flexibility across the group.

ACT is known for its ability to handle everything from low-volume prototypes to millions of units, providing not only coating services but also printing, assembly, and packaging. The company is equally comfortable applying complex EMI/RFI shielding systems as it is with high-end decorative finishes – including metallics, tinted lacquers, antimicrobial coatings, and textured or “cold touch” effects that mimic metal surfaces.

Built on Innovation and Flexibility

What truly sets ACT apart is its deep technical foundation. The business is still family-run, with Christine Hancock and Dr Yasin Zaka at the helm, alongside Yasin’s son, Dr Mujtaba Zaka, as technical director. Yasin and Mujtaba both hold PhDs in physics and chemistry and materials science, respectively. Between them, the technical team offers a wealth of academic and industry knowledge, helping ACT’s customers overcome complex coating challenges and stay ahead of market trends.

The company’s flexible set-up – with both robotic and manual capabilities – allows it to serve a broad range of projects, from premium low-volume automotive trim to mass-produced components. This flexibility, combined with ACT’s technical knowledge, makes them a trusted partner to over 300 customers worldwide, including major automotive OEMs and top-tier injection moulders.

After a tour around the company’s Western Road site and meeting members of ACT’s expert team on the factory floor, we sat down with Dominique, Christine and Mujtaba to delve deeper into the company’s ethos.

Will: We’ve seen a wide variety of products being treated today; how would you describe your target market?

Dominique: We operate in a 50/50 split between automotive and general industry. Our Tipton Road site is dedicated to high-volume automotive production, working with OEMs on interior and exterior trim. Western Road, on the other hand, is focused on lower-volume and specialist work for sectors like white goods, electronics, medical, defence, aerospace, and more. We’ve deliberately set the business up to balance these markets – it keeps us agile and reduces reliance on any single sector.

Christine: It also means that we offer a huge amount of flexibility to our customers. We can support a run of one thousand products or one million and retain the same point of contact for the customer. This means we can support a consumer product as it matures in the market or support an automotive client right from prototyping through to full production, which is a huge advantage for our clients.

What are your key products or services and USPs?

Christine: We offer both functional and decorative coatings for plastic components – including EMI and RFI shielding, antimicrobial coatings, metallic and pearlescent finishes, and special effects. We also provide additional services such as pad printing, assembly, packaging, and delivery.

Mujtaba: Technically, we’re quite unique. We have three bespoke robotic paint lines – each designed for single-, two-, or three-coat systems – alongside a comprehensive manual spray facility. This gives us the ability to support anything from one-off projects to full-scale production with consistent quality throughout.

After spraying, coated parts are stored on racks before being cured in one of ACT’s industrial ovens. Depending on the specification, this process can take several hours, at a temperature between 60 and 80oC.What sets you apart from your competitors?

Christine: Our technical expertise is a real differentiator. My co-founder, Dr Yasin Zaka, is a pioneer in shielding coatings and helped develop the technology more than 40 years ago. That legacy runs through the business. Our team includes two PhDs – Mujtaba in materials science and Yasin in physics – so we’re often helping customers specify or even develop the right coatings for their products, and we fully understand the science behind the process.

Mujtaba: A lot of companies follow trends, but we’re helping to set them. Our understanding of materials, paint technology, and formulation development puts us in a strong position to offer innovative and robust solutions.

Dominique: And we really value long-term relationships – many of our team have been here for decades, and we’ve built partnerships with both suppliers and customers that last. It’s a family business in the truest sense, and that shows in how we operate. Lots of our team have been here for ten, fifteen or twenty years, which is invaluable in terms of the skills they have developed, as well as indicating that we’re a stable business that staff want to work for.

You’ve experienced impressive growth since your foundation 25 years ago, what would you say were the key milestones on this journey?

Christine: One of the first major milestones came just a couple of years after we launched in 2000. We started out focused on EMI shielding, but it quickly became clear there was a growing demand for decorative finishes, so in 2002 we added manual spray booths for cosmetic coatings. That opened us up to new markets like white goods and bathroom products and really accelerated our growth.

Dominique: Then in 2008, we were awarded a significant project for BMW Mini, which required high-volume production. That’s when we installed our first robotic paint line and entered the automotive sector in a big way. We went from being just the ‘painter’ to becoming a full-service supplier – buying in mouldings, managing assembly, printing, packaging, and delivery. It changed our entire business model.

Christine: Another key point was in 2014, when we began working with Jaguar Land Rover. We invested in a new robot line for those projects and eventually opened a second site at Tipton Road to manage all high-volume automotive work. That allowed our Western Road site to focus on general industry customers – a move that gave both sides of the business space to grow.

Mujtaba: And now, we’re preparing for the next big milestone – supporting the shift to electric vehicles. With more electronics in EVs, demand for our EMI/RFI shielding is expected to grow. We’re also investing in new robotics and coating capabilities to support future finishes and evolving customer requirements.

What are the company’s plans for the next 12 months?

Christine: We’ve just completed a significant expansion at our Western Road site, including installing a new 6,000 sq ft mezzanine floor for extra storage – this has freed up space for additional manual spray capacity. Now our focus is on investing in our people – we’ve got a loyal, long-serving team and we want to continue supporting their development.

Dominique: Over at Tipton Road, we’re planning a major upgrade to one of our robotic paint lines to support the growing demand for electric vehicle (EV) projects. That’ll involve installing a second robot, allowing us to run multi-coat systems efficiently. By the end of next year, we’ll have three robotic lines, each tailored for different paint systems – single, two-coat, and three-coat.

Are you planning any events or attending any exhibitions in the next 12 months?

Dominique: We always exhibit at Interplas – it’s a great show for catching up with existing customers and meeting new ones, especially in the plastics sector. We also attend Paint Expo in Germany, which is an excellent event for keeping up with the latest developments in coatings technology.

Christine: We’re also planning an open day at our Western Road site, likely for autumn 2025. We’ve made a lot of changes here recently, and we want to open our doors and give people the chance to see what we’re about.

What is your company philosophy or mission statement?

Christine: Simply put, we want to be the best at everything we do. That applies across the board – from technical innovation and product quality to customer service and team development. We’re always evolving to meet changing market needs, and we encourage every member of our team to strive for continuous improvement.

Dominique: We often describe the business as a family – not just because we have many family units working for us, fathers and sons, brothers and sisters, but because we genuinely care about the people who work here. That culture has been central to our success.

Our visit to ACT made it clear why the company has remained a trusted coatings partner for over two decades. With unmatched technical knowledge, advanced production capabilities, and a genuine commitment to customer service, ACT continues to lead the way in the coatings sector – offering flexible, innovative solutions that meet the needs of a wide range of industries.

We’d like to thank Christine, Dominique, Mujtaba and the whole team for taking the time to show us around and share the ACT story.

Look out for the next edition of ‘PlastikCity on Tour’ to learn more about our excellent UK-based partners.

There are now well over 260 active partners represented on the PlastikCity site, many of which offer highly specialised products or services to our sector.

During our everyday course of business, we’ll be making a point of visiting as many of these partners as we can and using the time to better understand what they offer the market. We’ll then showcase them through this ongoing series of articles.

Maybe you can benefit from their services!

Applied Coating Technologies

+44 (0)121 238 0020

Website

Email