Bringing Any Texture to Your Mould Tools With Fimark

|

Getting your Trinity Audio player ready...

|

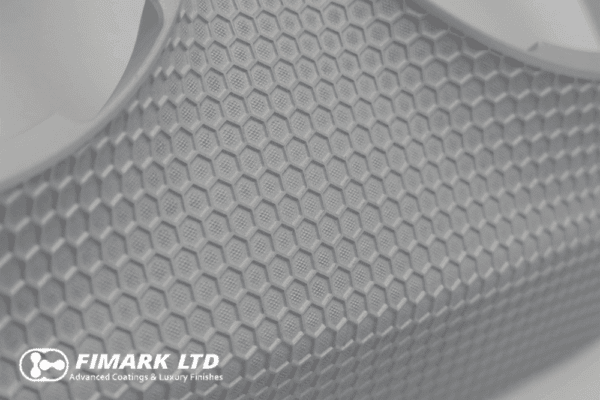

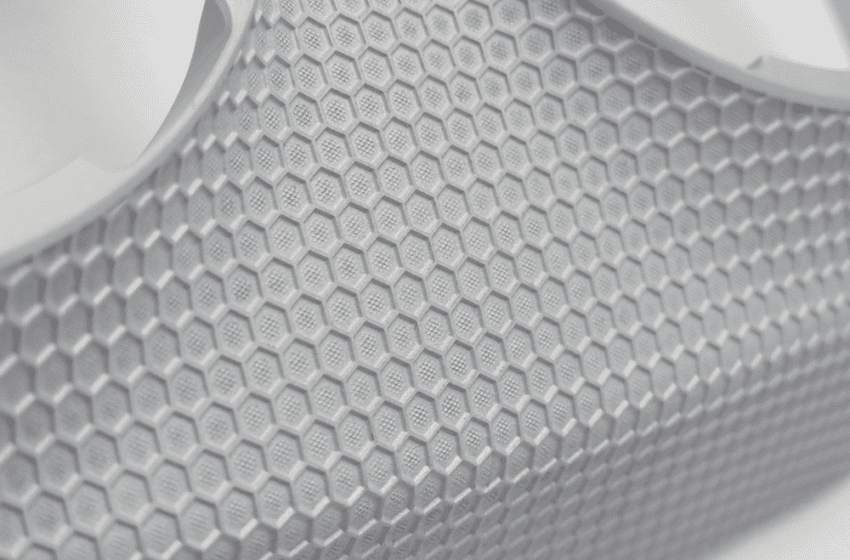

The ability to replicate intricate textures onto moulded parts is a game-changer, and Fimark specialises in making that possible. Using cutting-edge laser texturing technology, the company can apply virtually any texture to a mould tool. Whether it’s the grain of natural wood, the subtle pattern of leather or a custom design unique to your brand, its advanced 5-axis laser system ensures precision and repeatability that other methods simply can’t match.

How It Works

The process begins with your design vision. Fimark can work from CAD files or, for organic textures like wood grain, the company can scan a physical sample. This ensures the texture is replicated with unparalleled accuracy. Once programmed, its 5-axis laser technology applies the pattern directly to the mould tool perfectly adapting to complex geometries and ensuring consistency across all components.

Why Texture Matters

Texturing isn’t just about aesthetics, it’s also about functionality, branding and quality. A well-designed texture can:

- Enhance product appeal: Replicate premium materials like wood or leather.

- Improve functionality: Add grip, reduce glare or aid mould release.

- Elevate brand identity: Create a signature look that sets your products apart.

Real Results

One recent project involved creating a wood grain texture for a UPVC window manufacturer. By scanning a sample of natural wood grain and transferring it to the mould tool Fimark helped them achieve a realistic and durable finish on their window surrounds. The result? A product that looks high-end and stands out in a competitive market.

Ready to Add Texture to Your Tooling?

Whether you’re in automotive, tooling or another industry there are so many possibilities to improve your product and we are excited to discuss your project with you.

Read more on Fimark Ltd here.

Website

Email

+44 (0) 1932 245 226