APT’s Pearl Coat is More than a Colour

Automated Paint Technologies’ John Timmins explains how the process of applying pearlised colour coats onto plastic components is just as unique as the colour itself, and how this finish is becoming increasingly popular in the automotive sector.

The world of paint is full of wonderful colours. Some are bright and vibrant, while others are settled and calming. When it comes to applying paint onto a plastic component, processes and systems can be just as diverse as the colours themselves.

One new automotive colour, which you might see more often in the UK, is Ostuni White. Ostuni White is JLR’s new pearlised colour coat, available on some of their 22 model year cars.

But is it really that special, and does it contain real pearls? John Timmins, Director of Automated Paint Technologies (APT) and Quality Plated Plastics (QPP), is a real expert in plastic components and coating applications. John said:

“At Automated Paint Technologies, we apply a lot of different coatings such as solids, metallic and matt and gloss pearl coats. While pearl coats are part of our standard process, they are a stunning colour and my favourite finishes. There is, however, a difference in the material itself and the process.

“The solid paint system is a three-coat paint application system that consists of a primer, base coat and clear coat with a limited selection of solid hues – typically white, red, blue and black, but even in this range, there are a wide variety of shades to choose from within our portfolio.

“Our vast metallic paint systems, however, reflect light for a much brighter shine than typical solid paints. This effect comes from powdered metal flakes mixed into the paint with a coloured pigment, thus resulting in a glittery shimmer which makes the colour appear more vibrant, especially in direct sunlight. The paint system, however, is also a three-coat paint system.

“A pearl coat paint system is a four-stage application process that is achieved by applying primer, ground coat, pearl coat, and clear coat. Due to how our paint line is designed, we apply all four coats in a single process cycle.

“So, as you can see, whilst there are no real pearls in the paint, the process is indeed special.”

APT has detailed the pearl coat paint application below:

Primer coat

- This is normally the first coat to be applied to the plastic moulding. It serves as a shield that will protect the car from heat difference, corrosion and UV light, etcetera. It also acts as an adhesive between the basecoat and the component.

Base coat/ground coat

- This is the second stage after the primer and provides the base colour to the parts being painted.

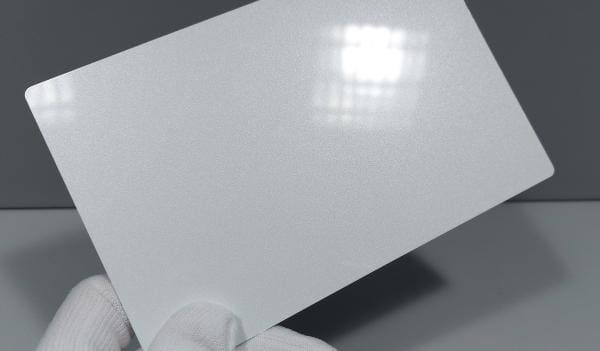

Pearlescent paint

- This contains several colourful pigments, which are referred to as “pearls”. It makes the paint have a sparkling finish on where it is applied; however, to manage this application during a single-stage process, the humidity and temperature of the environment are critical.

Clear coat

- Otherwise known as the top coat, it is the final application sprayed over the pearl coat. The clear coat is transparent in colour and can be applied as a matt or gloss finish. It protects the paints underneath from the environment and is very durable. It will also withstand the usual scratching, stone chips, cleaning products and everyday wear and tear and is strong enough to resist UV rays.

For more information about APT or QPP, visit www.apt-limited.com or www.qppltd.co.uk.

Automated Paint Technologies

+44 (0)121 521 1300

Website

Email