BEC Group Upgrades 3D Printing and Scanning Facilities

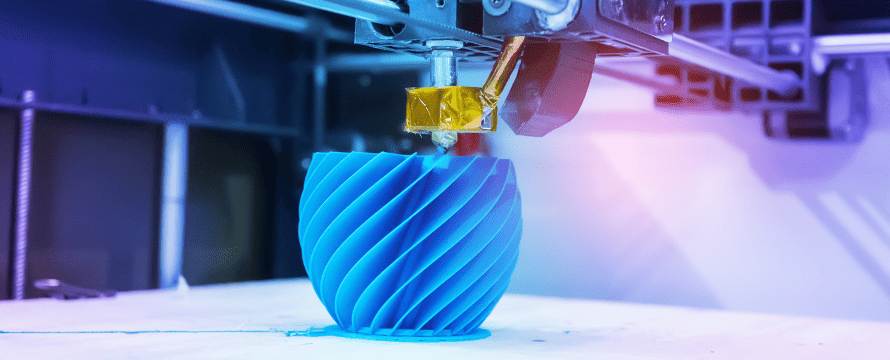

New Milton-based technical moulder BEC Group has upgraded its 3D printing and scanning suite with two new investments to make tooling and moulding development easier and quicker for its customers.

BEC clients can now reverse engineer projects from a legacy part or those without CAD drawings available. By bringing in a 3D part to BEC, scanning it with the new Einscan Pro HD 3D Scanner and producing a CAD file from this scan, clients can now create a traditional steel mould tool and produce mouldings from this. The Einscan Pro HD captures high-resolution data at super quick speeds to produce highly accurate CAD drawings.

In addition, BEC’s new Fusion F410 3D printer will be utilised for prototyping, an important step that ties in with the design for manufacture process carried out by the design team. Using a 3D printer can remove 80% of the costs associated with prototyping through typical plastic injection moulding. The design can then be tweaked and reprinted to assess suitability for use and get a feel for the finished product. 3D printing prototypes can also be created in a far shorter timeline than injection mouldings – ideal for prototyping.

The Fusion F410 3D printer has print speeds of up to 250mm per second and a layer resolution as low as 20 microns for increased precision. A huge range of printable plastics can be used, including PLA, ABS, nylons and acrylics, to allow for complete customisability to designs.

Want to know more about BEC’s 3D printing and scanning suite and how it can benefit your project? Get in touch with the team using the details listed below.

BEC Group

+44 (0)1425 613131

Website

Email