Borough Completes IATF 16949 Quality Audit with Flawless Results

|

Getting your Trinity Audio player ready...

|

It is very gratifying to report that Borough has successfully completed its annual IATF 16949 surveillance audit with zero non-conformities, which reflects the company’s unwavering commitment to quality excellence and continuous improvement in automotive manufacturing.

For those unfamiliar with this certification, this achievement represents far more than a routine compliance exercise. It demonstrates the company’s dedication to maintaining the highest standards in every aspect of its injection moulding and electroplating operations.

Understanding IATF 16949 certification

IATF 16949 is the global automotive quality management standard that defines the requirements for quality management systems in the automotive industry. Developed by the International Automotive Task Force, it builds upon the foundations of ISO 9001, adding automotive-specific requirements to address the unique challenges of this demanding sector.

This standard goes beyond basic quality management, encompassing everything from defect prevention and supply chain management to customer satisfaction and continuous improvement. It’s specifically designed to address the automotive industry’s needs, including zero-defect manufacturing, lean principles and robust risk management.

The certification isn’t just a badge of honour, but a prerequisite for supplying major automotive manufacturers worldwide. Without IATF 16949 certification, companies simply cannot participate in global automotive supply chains at the tier levels where Borough operates.

What this means for Borough’s clients

IATF 16949 certification provides tangible benefits that directly impact Borough’s clients’ success. First and foremost, it guarantees that every component the company manufactures meets the exacting quality standards demanded by global automotive brands.

Attaining and maintaining these standards has earned the company partnerships within the supply chain to provide components for some of the most highly regarded automotive brands, including Rolls-Royce, Jaguar Land Rover, Bentley, Mercedes and Nissan.

The standard requires rigorous process control and statistical process monitoring, which means greater consistency and reliability in every batch of components the company produces. The company’s clients can trust that parts manufactured today will be identical in quality and performance to those produced months from now.

Risk management is another crucial benefit. IATF 16949 requires comprehensive supplier evaluation, contingency planning and proactive problem-solving approaches. This translates to more secure supply chains and fewer disruptions for the company’s clients’ production schedules.

Perhaps most importantly, the standard promotes a culture of continuous improvement. The company is required to actively seek opportunities to enhance its processes, reduce waste and improve efficiency. These benefits ultimately flow through to its clients in the form of better quality, shorter lead times, competitive pricing and sustainability benefits.

Inside the surveillance audit process

The annual surveillance audit represents the culmination of the company’s comprehensive quality approach. Before any external audit takes place, the company conducts thorough internal audits of its own processes to ensure it identifies and addresses any potential issues before independent assessors arrive.

The surveillance audit itself is a detailed examination conducted by accredited certification bodies, which in this case is SGS [one of the world’s leading service providers], to verify ongoing compliance with IATF 16949 requirements. These independent auditors scrutinise the company’s documentation, observe live production processes and interview personnel at all organisational levels to verify that the quality management system not only remains robust and effective, but is embedded within the entire production process.

The audit covers every aspect of the integrated operation, from management review processes and internal audit effectiveness to customer complaint handling and corrective actions. Auditors trace components through the complete process chain, from raw material receipt through injection moulding and electroplating to final dispatch to ensure full traceability and process control.

They examine the company’s statistical process control data, review customer satisfaction metrics and assess how non-conforming products are handled. The zero non-conformities result means every aspect of the operation met or exceeded the standard’s requirements, with no deviations, no areas requiring improvement and no corrective actions needed.

Continuous excellence in action

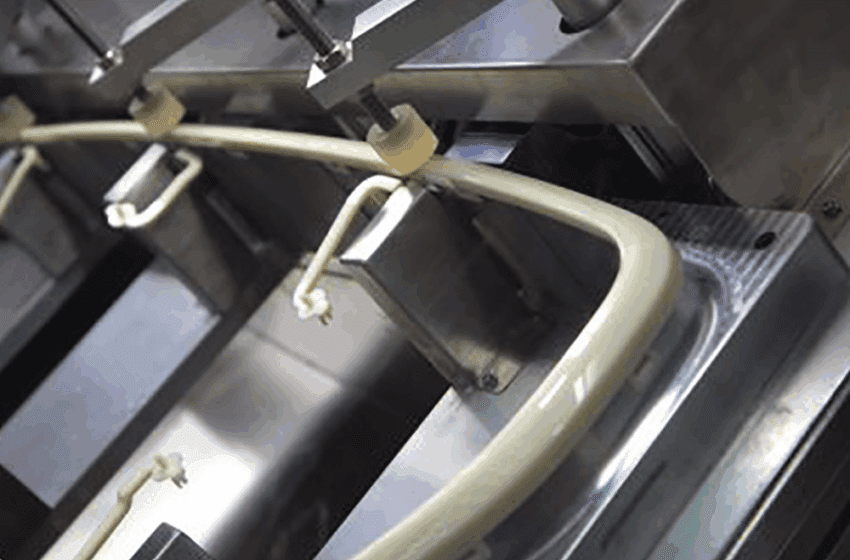

This surveillance audit success isn’t an accident. It reflects Borough’s systematic approach to quality management that has been refined over decades. The company’s integrated manufacturing model, combining injection moulding and electroplating under one roof, actually makes it easier to maintain the traceability and process control that IATF 16949 demands.

For its clients, this certification and audit success provides confidence that Borough will continue delivering the consistent, high-quality components their brands depend upon. It’s one more reason why global automotive manufacturers trust the company with their most visible and demanding applications.

Read more news from Borough Chrome here.

+44 (0) 1702 425425

Website

Email