Summit Process Cooling Enhances Carclo’s Efficiency Alongside Frigel Microgel Systems

|

Getting your Trinity Audio player ready...

|

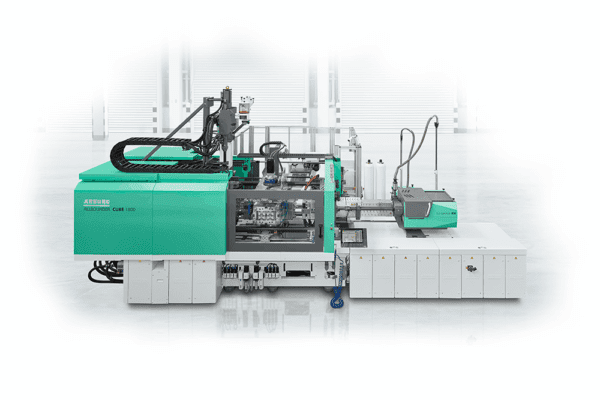

Carclo, a global leader in precision manufacturing, has built its reputation on the production of high-quality diagnostic and medical devices, as well as advanced technology components. The company’s commitment to innovation and precision has established it as a trusted partner in sectors where reliability and quality are paramount. To further enhance operational efficiency, Carclo aimed to optimise its injection moulding processes by reducing cycle times while maintaining its exceptional product standards.

Injection moulding is a critical process in Carclo’s operations, and even small efficiency improvements can have a significant impact on productivity and profitability. To achieve this, Carclo turned to Summit Process Cooling, a company with over 30 years of expertise in providing tailored water-cooling solutions. Summit Process Cooling has a proven track record of delivering well-engineered, cost-effective cooling systems across various industries, making it an ideal partner for Carclo’s ambitions.

To address Carclo’s challenges, Summit proposed a trial of Frigel Microgel units—compact, high-performance temperature control systems tailored to optimise plastics manufacturing cooling processes. These units offered precise temperature control, promising to enhance process stability and reduce cycle times. Despite initial scepticism from Carclo’s Manufacturing Director, Andy Fay, a trial was arranged in late 2024 to demonstrate the system’s capabilities.

“As part of our continuous improvement program, we engaged with Summit to review our process cooling for our mould tools,” commented Andy Fay, Manufacturing Director for Carclo. “Summit recommended the lineside Microgel units to support controlled cooling for each mould tool and organised a single unit, Model RSM80/9, for the initial trial. Summit’s engineer, Stuart, was exceptional, providing full support throughout the trial and ensuring that all team members had the necessary information. The unit achieved a cycle reduction of 10%, which significantly improved production output.”

The trial involved installing single and dual-zone Microgel units to evaluate the real-world performance. The results exceeded expectations: a cycle time reduction of 0.6 seconds brought Carclo’s cycle time below 9 seconds, significantly boosting efficiency and output.

Following the trial’s success, Carclo expanded its investment. “We purchased two more units, specifically lineside dual chiller units, allowing us to supply two moulding machines from one unit,” Andy added. “The models supplied were RSD80/12 units with the added benefit of independent control. Both units were installed with Summit’s support, and the trials resulted in a cycle time reduction. Upon reviewing the data, we observed an average cycle time reduction of 9% across the four manufacturing lines. Economically, this is estimated to provide a payback for the units in under 12 months.”

The enhanced efficiency achieved with the Microgel units significantly increased Carclo’s production rate, even presenting a welcome challenge of not being able to keep up with packaging materials for the finished products. This boost in productivity has directly contributed to higher profitability and improved Carclo’s ability to meet customer demands.

The project also underscored the importance of skilled technical support in ensuring successful implementation. Andy Fay praised Stuart Nesbitt from Summit Process Cooling for his pivotal role in the project, stating, “I can only applaud his engineering installation skills and exceptional telephone support that allowed us to overcome an issue we had as we commenced a tool change.” Stuart’s expertise and responsiveness were instrumental in the seamless commissioning of the Microgel units, giving Carclo the confidence to maximise its potential.

This collaboration between Carclo and Summit Process Cooling demonstrates the measurable impact of advanced cooling technologies and precision engineering. The Frigel Microgel systems have transformed Carclo’s production process, reducing cycle times, enhancing process stability, and delivering consistent efficiency improvements. These tangible results reflect Carclo’s commitment to innovation and quality, ensuring the company continues to meet the high standards its customers expect.

Summit Process Cooling’s tailored approach and dedication to customer success played a critical role in the project’s achievements. By understanding Carclo’s unique requirements and delivering a solution that exceeded expectations, Summit strengthened the partnership between the two companies. This success story highlights not only the operational benefits of advanced cooling systems but also the value of collaboration in driving innovation and efficiency.

Looking ahead, the adoption of Frigel Microgel systems positions Carclo to remain at the forefront of precision manufacturing. The partnership with Summit Process Cooling sets a strong foundation for continued success, enabling Carclo to push the boundaries of efficiency, quality, and customer satisfaction.

Read more news from Summit Systems here.

Summit Systems

+44 (0)1827 265 800

Website

Email