ENGEL Debuts WINTEC e-win 1800 with All-electric Precision at K 2025

|

Getting your Trinity Audio player ready...

|

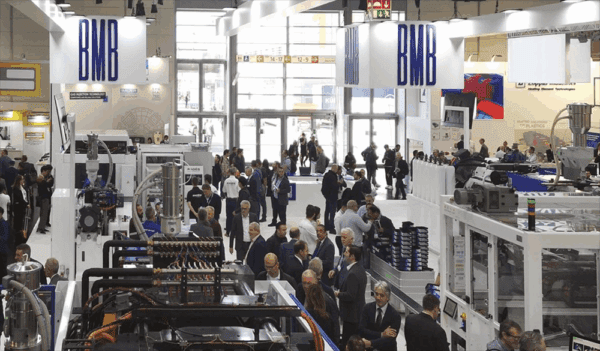

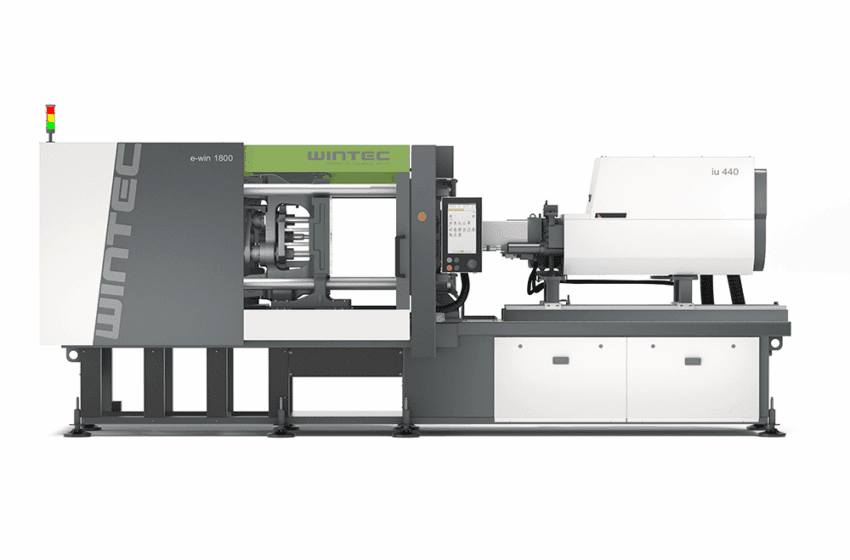

With the all-electric e-win 1800, ENGEL presents a WINTEC injection moulding machine based on the proven technology of the ENGEL e-mac for the first time at K 2025. The e-win series combines a compact design and high precision with an especially attractive price-performance ratio. While ENGEL delivers tailor-made high-end technologies, WINTEC targets users who need robust standard machines available at short notice. The e-win is designed for the small and medium-sized machine market and ensures short delivery times and customer-focused standardised engineering based on ENGEL’s expertise.

Produce more quickly and economically

The new WINTEC e-win combines proven ENGEL technologies with consistent standardisation for cost-effective series production. Users benefit from an all-electric injection moulding solution that offers precision and parallel movements along with a robust design, high energy efficiency and short delivery times. The WINTEC e-win ensures maximum productivity, stable processes and a long-term, future-proof investment in the standard machine segment.

At the WINTEC stand, an e-win with 1,800 kN clamping force demonstrates its efficiency in a compact production cell: An 8-cavity mould produces flip-top closures made of random PP with a shot weight of 32 g – in a cycle time of under 10 seconds and with consistently high part quality.

Precise injection unit for shorter cycle times

An electric ball screw drive combined with a belt drive powers the nozzle movement. Two ball screws enable fast, uniform injection with high repeatability. This setup reduces cycle times, ensures centric and precisely adjustable contact force, minimises the risk of material leakage and maintains consistently high part quality. In addition, the swivelling injection unit allows for quick and easy screw changes.

Efficient clamping system with high dynamics

The proven drive system – consisting of a servomotor, ball screw and belt drive – ensures maximum power transmission efficiency and dynamic response of the clamping unit, delivering dry cycle times in line with market standards. The 5-point toggle lever mechanism allows large opening strokes and automatically adjusts the mould installation height. A reinforced frame structure on the moving platen minimises deformation, optimises force distribution and enables burr-free parts. The linear guides operate with minimal friction, reducing maintenance, improving machine cleanliness and enhancing reproducibility.

Less scrap thanks to digital assistance systems

This series also supports ENGEL’s digital assistance systems. The machine features the iQ weight control system, which analyses the filling behaviour during each shot and adjusts the holding pressure curve in real time within the same cycle. This reliably compensates for fluctuations in the material viscosity and reduces scrap by up to 50%. Users benefit from higher productivity and lower part costs.

WINTEC relies on the proven C3 control system, which shares the same intuitive user interface as ENGEL’s CC300. For operators already familiar with ENGEL machines, there is no need to adapt. For new users, the interface is highly intuitive and easy to learn.

Powerful and stable ejector system

The ejector also operates via a servo drive with two ball screw spindles. This ensures high ejector force, outstanding system stability and low maintenance costs – ideal for durable, reliable processes.

Flexible mould area for a wider range of applications

Large platen surfaces and the near-frictionless movement of the mould platens via linear guides enable the use of large-format moulds while maintaining excellent platen parallelism. This extends mould life and ensures consistently high part quality.

Conclusion: Cost-efficient and ready to run

With the new WINTEC e-win, injection moulders benefit from significantly lower reject rates, reduced operating costs, and minimal maintenance requirements – all while achieving high precision and stable processes, as well as optimised footprint. The all-electric machine combines proven ENGEL technology with consistent standardisation, offering an attractive overall package for companies seeking readily available, economical solutions for series production. The use of digital assistance systems such as iQ weight control ensures consistently high part quality and sustainably reduces unit costs.

Read more news about ENGEL here.

ENGEL

+44 (0)1926 335000

Email

Website