ENGEL Increases Efficiency at Aptar Pharma

ENGEL recently provided Aptar Pharma, a global manufacturer of consumer dispensing packaging and drug delivery devices, with an integrated cleanroom solution to produce miniature components within the pharmaceutical industry precisely and efficiently.

What all eye drops used to share was an unavoidable contact with bacteria after opening. The common systems on the market are, therefore, often single applicators. A sustainable alternative to pharmaceutical packaging is manufactured by Aptar Radolfzell GmbH in a cleanroom: a multiple dosage system. As a closed system, this offers the necessary protection against microbiological contamination, which reliably prevents the premature deterioration of the drug.

“Our applicator delivers the medicine drop by drop and is free of preservatives. That is the added value of the system,” says Ingo Korherr, Production Manager at Aptar Pharma.

“One advantage here is that it is not a one-time application, which is not ecological and produces a lot of waste,” adds Ralf Fichtner, Site Manager of Aptar Pharma in Eigeltingen in Southern Germany.

How is pharmaceutical packaging produced in the cleanroom?

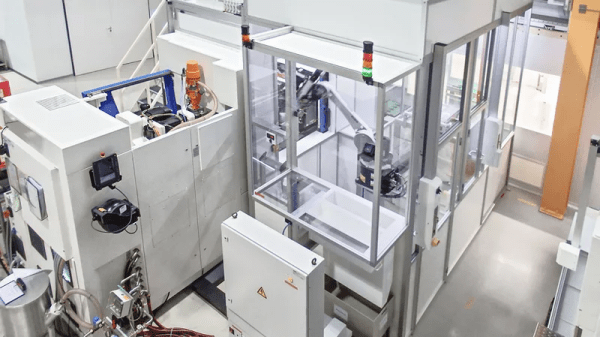

The OSD (Ophthalmic Squeeze Dispenser) consists of seven plastic parts. For the production of the applicator and the spray pins, investment was made in two new ENGEL production cells for the Eigeltingen site, the second production site of Aptar Radolfzell GmbH in addition to Radolfzell.

- The applicator is produced from polypropylene (PP) in a 32-cavity mould on an ENGEL e-victory 740/220 injection moulding machine.

- The total shot weight is 30.5 grams. An ENGEL e-victory 50/90 produces the spray pin from TPE in a 16-cavity mould with a total shot weight of 1.97 grams.

- Both components are product-carrying. Against the background of microbiological purity, both production cells for the pharmaceutical packaging parts are encapsulated as a class ISO 7 cleanroom.

What advantages do tie-bar-less injection moulding machines offer for the production of pharmaceutical packaging in the cleanroom?

The e-victory injection moulding machines with an electric injection unit and servo-hydraulic clamping unit offer advantages – both for the detailed pharmaceutical injection moulded parts produced in the cleanroom and the multi-cavity moulds. The reason is the tie-bar-less clamping unit. This provides sufficient space for large multi-cavity moulds, even on machines with low clamping forces. The excellent parallelism of the mould fixing platens is also maintained during clamping force build-up and injection. The patented Force Divider distributes the clamping force evenly over the mould fixing platens. This ensures consistently high moulding precision across all cavities. These were the factors that tipped the scales in Aptar’s favour when it came to investing in machines from this series.

“The ENGEL servo-hydraulic clamping unit runs like clockwork,” says Andreas Gräber, Manager of Injection Moulding Services at Aptar Pharma.

What added value does the cleanroom system solution from a single source offer?

The production process for pharmaceutical packaging in the cleanroom is fully automated. The components are removed by ENGEL easix robots. One of the decisive factors for the use of jointed-arm robots was the limited space available in production. The ENGEL robot control unit is integrated into the CC300 control unit of the injection moulding machines, which makes it particularly easy for Aptar to use jointed-arm robots. The integrated production cell offers a uniform operating logic.

Why is ENGEL the right partner for cleanroom production of pharmaceutical plastic parts?

Choosing partners with expertise is elementary for Aptar Pharma.

“ENGEL listened and implemented our requirements and wishes. ENGEL’s innovative strength struck the right chord with us,” says Ralf and announces the next joint step: digitalisation. “We are already well on the way here.”

The ENGEL customer portal e-connect is the first step. Andreas, who has been with Aptar for 30 years, uses this tool intensively. “E-connect is really running great. I use the platform for machine management and have the complete plant documentation at a glance,” says Andreas.

Success factors for the cleanroom production of miniature components in the pharmaceutical sector

- Integrated system solution from a single source because coordinated machine and robot movements reduce handling time.

- The tie-bar-less clamping unit of the injection moulding machine because the large multi-cavity mould fits on a comparatively small injection moulding machine.

- The high moulding precision of the e-victory injection moulding machine because the detailed miniature parts place the highest demands.

- The easix jointed-arm robots because this allows flexible part handling and space-saving integration.

Visit www.engelglobal.com/en/uk/ to learn more about ENGEL’s products, processes, and services. Click here to read more news from ENGEL.

ENGEL

+44 (0) 1926 335000

Website

Email