ENGEL Accelerates Production of Automotive Plastic Parts

In a recent case study, Zechmayer GmbH was looking for a solution for a wide range of moulds for a wide variety of injection moulding processes and shot weights, to which ENGEL supplied a complete system based on a single injection moulding machine.

Multi-talent for a wide range of applications sought and found

“The only thing it can’t do is fly,” says Jörg Zechmayer, Managing Director of Zechmayer GmbH in Grafenwöhr, “but almost everything else, because we have big plans for this injection moulding machine.”

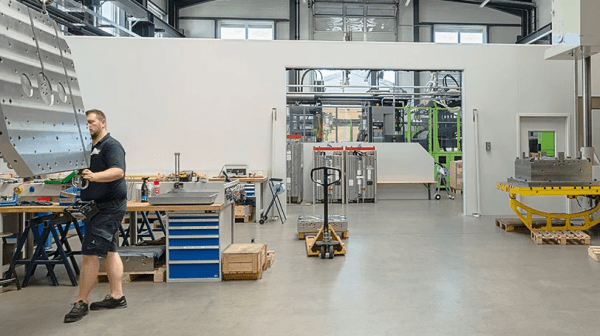

The specifications for the new pilot plant machine of the tool and mould-making company are extremely extensive: very large, but also very small shot weights, back injection, flooding, injection-compression moulding, foaming and multi-k – all this should be possible on a single injection moulding machine. Visible and decorative parts for car interiors and exteriors, among others, make high demands. The machine is equipped with various moulds to produce sophisticated automotive plastic parts. The final result in Zechmayer’s technical centre is a machine that is unique in the world.

The machine in detail

The machine in detail

ENGEL accepted the challenge and met all requirements in the end. A complete solution was implemented to accommodate a wide variety of moulds for the production of automotive plastic parts. The decision was made in favour of a duo injection moulding machine in the combi M version with a clamping force of 1,500 tonnes and a swivel platen. The swivel platen divides the clamping area so that two moulds can be accommodated in parallel, either for multi-component injection moulding in a single operation or to double the output with two identical moulds. The duo combi M is equipped with two injection units for this purpose. One is located on the fixed mould fixing platen, a second, “travelling” one on the moving one. Something special in itself, the combi M version was not enough for Zechmayer. The moving platen was additionally equipped with a turntable and a third injection unit was installed in piggyback position of the main injection unit.

Equipped for a high range of shot weights

Besides the main unit, a 70mm auger, the height-adjustable piggyback unit with a 50mm auger cannot be overlooked. The third unit also has a 50mm auger diameter. For the size of the machine, these are remarkably small screw diameters, which account for the great flexibility in multi-component injection moulding. Shot weights between 70 grams and 2.2 kilograms are processed. Furthermore, the pilot plant machine has a complete robot handling system, an ENGEL viper 40 linear robot with removal and deposit function, which is fully integrated into the CC300 machine control system.

Ready for a wide range of different production processes

The machine is equipped to accommodate a wide variety of tools for the production of automotive plastic parts using a wide range of processes: Among others, for back injection of foil, wood, metal and fabric, for injection compression moulding and flooding with polyurethane. Gas and water injection technology is available for reducing component weight, as is MuCell for foam injection moulding. For multi-component technology up to 3K, the rotary table and the turning plate are used. The maximum possible tool weight is 30 tonnes. The clear tie bar width is 1530mm, moulds up to a height of 1800mm can be installed, whereby the installation heights are variable in the open-close direction from 375 to 2275mm. This enormous range is possible because the turning plate can be dismantled, another special feature of the duo combi M from Zechmayer. Due to the available floor space, a body length shortened by almost two metres was necessary – ENGEL was also able to meet this requirement.

High requirements for automotive plastic parts in the visible and decorative areas

“For visible and decorative parts, 2K technologies are almost always required. An injection moulding machine for our applications must be capable of both back-moulding foils and flooding with polyurethane to form a high-gloss and scratch-resistant protective layer,” says Dominik Will, Project Manager for Plastics Technology at Zechmayer, describing the minimum requirements.

“Design is an important differentiator in the vehicle industry – both on two and four wheels. We are observing a trend towards more filigree structures and back-moulded lighting technology. Accordingly, shot weights are becoming smaller, with mould sizes remaining the same or even increasing,” adds Mario Oppelt, Sales Engineer at ENGEL Germany, who has been involved in the project from the very beginning. “The process engineering possibilities of this individual duo combi M are almost endless due to the different combinations of the installed technology packages.”

When simultaneously back-moulding and over-moulding an IMD film, the combi M design really comes into its own in producing automotive plastic parts. “We wouldn’t have got this project without investing in the new machine,” says Jörg Zechmayer. Especially since the application with variothermal mould temperature control is also demanding in terms of process technology. “The complexity of the applications keeps increasing,” explains Zechmayer. “In addition, we also want to accompany research work in the future. That is why we have invested with foresight. Our machine is truly unique in its versatility.”

A lot of intelligence for process optimisation

For sampling and future process optimisation or development tasks, precise and intelligent machine control and accurate documentation of all parameters are indispensable. The machine in Zechmayer’s technical centre is also prepared for this: the intelligent assistance systems iQ weight control and iQ flow control are helpers for stable processes and the documentation of all settings. “We can give the customer all the details for the series production process. This allows him, for example, to temper with minimal energy input and document the CO2 footprint of his component,” describes Dominik Will.

Based on the measurement results of the e-flomo temperature control water distributor, iQ flow control optimises the temperature control process. The software automatically compensates for temperature differences in each distributor circuit, creating constant temperature control ratios. iQ weight control adjusts the changeover point, injection profile and holding pressure to the current conditions shot by shot. The effects of external influences and fluctuations in the raw material are thus compensated for fully automatically.

Pre-equipment has been taken into account for all options that have not been directly installed so that the Zechmayer mould and die maker can also adapt the duo combi M to new requirements of its customers or development partners at a later date. “Even today, our very special injection moulding machine opens up many new options for us in product, mould and process development,” says Jörg Zechmayer, looking forward to the challenges ahead. “I’m looking forward to the prototypes for control panels for coffee machines and household appliances or light rails for the automotive sector.”

Do you produce automotive plastic parts and have similar challenges in your company? ENGEL offers you individual solutions – for more information, contact the team using the details below. Alternatively, visit www.engelglobal.com/en/uk/ to learn all about ENGEL’s products, processes and services.

ENGEL

+44 (0) 1926 335000

Website

Email