ENGEL: Remote Maintenance of Injection Moulding Machines Compared

At ENGEL you have the choice between two remote maintenance tools. The feedback from the market on e-connect.24 and e-connect.expert view is positive. The usage rate of remote machine maintenance is increasing, and the success stories are piling up.

In the event of a machine breakdown, you urgently need technical experts to repair malfunctions and recommission your machine again. The shortage of skilled workers makes such emergency situations difficult. Experts are not always available on site within a short time. In this case, our digital service solutions can help. They enable remote maintenance of your machine. Our service experts connect to your system via remote access and remedy the breakdown from afar in up to 75 % of cases!

What remote maintenance options for machines does ENGEL offer?

e-connect.expert view:

Often, a short video call with a smartphone, tablet or smart glasses is enough to rectify faults. With the help of the camera, they show us directly at the machine where the cause lies. And solve the problem together with the ENGEL service expert.

e-connect.24:

If option 1 is not sufficient, our experts access machine data via a secure online connection to rectify the fault.

Our remote maintenance tools support you to fix a wide range of breakdowns – quickly and easily from a distance.

e-connect.expert view: How does our Remote Assistance tool with Augmented Reality work?

With e-connect.expert view, we offer remote troubleshooting using only your smartphone. In case of a service case, you receive remote assistance via an audio and video connection with augmented reality elements.

What advantages does e-connect.expert view offer?

Two colleagues from the hotline report on their experiences.

Stefan Isaksson, hotline expert at ENGEL Sweden, reports: “The use of e-connect.expert view is particularly helpful when servicing machines with an older generation of control units. With the tool, it is possible to assist the customer with calibration or troubleshooting remotely.”

Fernando Espino Servin, hotliner at ENGEL Mexico, reports on a specific customer case: “A customer contacted us because the touchscreen of his machine control unit was black. This meant he could not operate his machine“. Fernando recommended that the customer connect to him via e-connect.expert view to investigate the problem remotely. “That’s how I found out that the CC300 panel had internal damage. That was responsible for the black display.”

The solution for the customer was eventually to buy a new CC300 panel. “When the new panel arrived at the customer’s premises, we did the installation and connection together via e-connect.expert view. I gave him the instructions via the smartphone and was able to watch him carry them out directly on the machine. This is how we got the machine ready for production again thanks to remote maintenance.”

e-connect.24: How does our remote maintenance tool with direct access to the machine work?

Whether at the weekend, on the night shift or during office hours – with the e-connect.24 remote maintenance tool, our service experts can securely access your machine control via an open online connection. You get your faults under control quickly and around the clock.

What advantages does e-connect.24 offer?

Learn about service cases that were successfully solved with the help of e-connect.24.

Marcel Grasser, our Technical Support Expert from Schwertberg, Austria, reports: “Our customer described the following error pattern to us: In every cycle, the mould bounced by a few tenths of a millimetre during the movement transition between mould closure and clamping force build-up.

With the help of a service technician, we jointly made oscilloscope recordings with different settings over several days. A big advantage of e-connect.24 was that we could immediately evaluate the recordings of the measuring device while the technician was already starting the next tests. All tests performed could be documented in our back office. This is a great advantage for the technician, who was relieved of the time-consuming documentation work. Every test and every parameter change, no matter how small, must be logged so that structured troubleshooting is possible at the end of the day. After a few days, the fault could be repaired and the machine was handed back to the customer.

“e-connect.24 offers a variety of functionalities that make it easier for us to analyse faults and perform remote maintenance on the machine. Especially if the operator on the customer side is familiar with the injection moulding machine. We would never have been able to carry out troubleshooting at this speed without e-connect.24.”

How do ENGEL solutions for remote machine maintenance work?

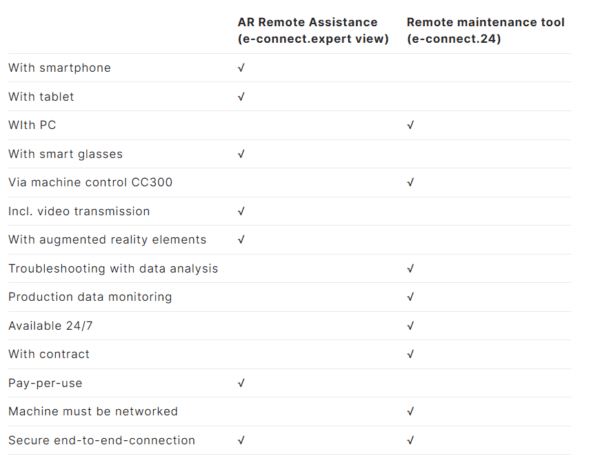

Remote machine maintenance: For which support case is which remote maintenance tool best suited?

Remote machine maintenance: For which support case is which remote maintenance tool best suited?

Whether you need a quick intervention or a comprehensive machine data analysis, we have the right remote maintenance solution for your service case. Our remote maintenance tools support you to avoid breakdowns in a wide range of cases – quickly and easily from a distance.

e-connect.expert view is used when a short video call with a mobile end device is sufficient to repair malfunctions on the machine. For Injection moulding machines with older control generations cannot be connected online so e-connect.expert view is particularly helpful here.

e-connect.24 is the right solution when a video call is not sufficient for troubleshooting. Complex faults affecting process stability, product quality or cycle times are solved via e-connect.24. The service experts access the machine data via a secure online connection. Extensive data analyses reveal possible sources of error. In this way, you avoid tedious troubleshooting and save time and money.

Read more news from ENGEL here.

ENGEL

+44 (0) 1926 335000

Website