Fairgrieve Compression Moulding Set for Record-Breaking Turnover in 2025

|

Getting your Trinity Audio player ready...

|

Fairgrieve Compression Moulding is on course to achieve a record turnover in 2025 as it has been buoyed by several new contracts, including a multi-million pound order to supply hundreds of thousands of electrical parts for worldwide distribution.

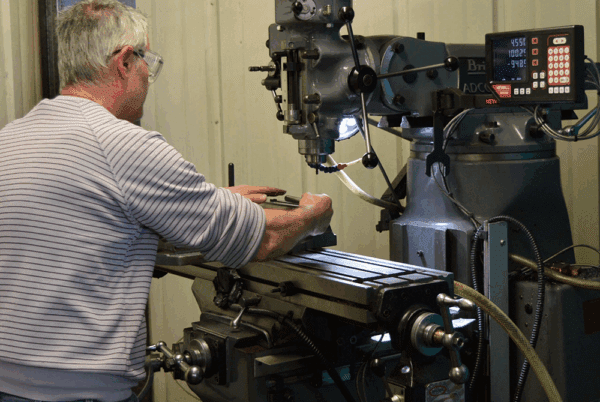

Such is the demand for the firm’s specialist compression moulding expertise – and the capabilities of its industry-leading machinery at its Washington factory – that the business expects to double the size of its workforce over the next few months to meet demand.

A recruitment drive has already been launched, with new employees being trained under the watchful eye of talented and experienced Production Manager, Johnathon Hutchinson, who started his career as a young apprentice with the business.

Having already moved to 24-hour shift work Monday to Friday, the business plans to introduce seven-day working once the team is fully trained.

Having overseen an incredible business transformation since joining in 2021, Managing Director Barry Davidson says this new work complements the current product portfolio and brings with it additional security and profitability.

“It is amazing to see such high levels of demand for new work at a time when the manufacturing sector in the UK is struggling he said.

“I think we’re reaping the rewards of a lot of very hard work done a couple of years ago to transform the business, to become much more efficient, whilst bringing innovation and inspiration into our work culture.

“Manufacturing always has its ups and downs, and some contracts which we hoped would come our way last year didn’t come into fruition.

“However, from last November onwards, we’ve met with so many new customers, which has led to new innovative projects. Our name is really spreading at present, and that is why we have launched a recruitment drive, which will see us add new faces to the team, and provide each with full training, over the coming months.”

Demand for new and old products

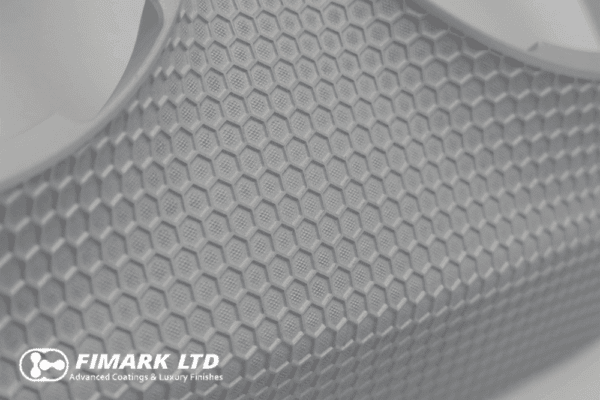

This latest contract has seen a major international company turn to Fairgrieves for their knowledge and experience of manufacturing specialist electrical components, which will be supplied into a global market.

Mr Davidson added: “This latest contract is in addition to other major contracts recently won to supply high volumes of manufactured parts into diverse industrial sectors like confectionery, construction, mining and the automotive truck market.

“The name Fairgrieves is now synonymous with being an innovative thermoset moulding specialist supplying into a vast number of manufacturing sectors.”

Read more from Fairgrieve Compression Moulding here.

Fairgrieve Compression Moulding

0191 415 9292

Website

Email