5 Ways the FANUC Roboshot Improves Your Injection Moulding Efficiency

|

Getting your Trinity Audio player ready...

|

In an increasingly demanding manufacturing environment, the pressure is on to deliver high-quality plastic parts faster, more reliably, and at lower cost. Whether you’re moulding parts for the automotive, medical, electronics, or packaging industries, the FANUC Roboshot all-electric injection moulding machine offers a game-changing advantage. FANUC’s Roboshot Sales Manager, Sam Carr, takes a closer look at five critical ways the FANUC Roboshot can improve your injection moulding efficiency and make your production floor more competitive.

Unlike traditional hydraulic presses, the Roboshot leverages our uniquely designed electric drive technology to deliver precision, repeatability, and energy savings at a level few machines can match.

Here’s a closer look at five critical ways the FANUC Roboshot can improve your injection moulding efficiency and make your production floor more competitive:

1. All-Electric Drive System

At its core the Roboshot efficiency is its servo-driven, all-electric design. Every major axis—clamping, injection, screw recovery, ejection—is controlled independently by high-performance AC servo motors, eliminating the sluggishness, variability and unpredictable nature of hydraulic systems.

Key Benefits:

- Faster response times: Servo motors react in milliseconds, minimising idle time between machine movements.

- Tighter control over process parameters: Achieve precise speed, pressure, and position control at every stage of the cycle.

- Reduced cycle time: Depending on part complexity, many customers report cycle time reductions of 10–30% over comparable hydraulic machines.

Real-world impact: More parts are moulded per shift, faster delivery to customers, and increased plant capacity without needing more floor space for additional machines.

2. Energy Efficiency

The Roboshots energy consumption is typically 40–70% lower than hydraulic or hybrid machines. Instead of consuming power continuously (as hydraulic pumps do), the Roboshot only draws power when movement is required. In addition, FANUC’s energy recovery system regenerates power during deceleration of the injection and clamp drives.

Key Benefits:

- No idling energy draw: Servo motors stop when the machine stops.

- Energy regeneration: Converts kinetic energy from motor braking into usable power.

- No oil cooling system: Eliminates energy wasted in heat generation and coolant systems.

Real-world impact: For high-volume operations, this can mean tens of thousands in annual energy savings, faster ROI, and a much smaller carbon footprint.

3. Superior Part Quality

The Roboshot offers ±0.01 mm accuracy and repeatability across long production runs. The machine’s CNC-based control system, coupled with real-time feedback from high-resolution sensors, ensures that every shot is executed with near-identical force, speed, and position.

Key Benefits:

- Consistent part weight and dimensions

- Minimised part warpage and sink marks

- Stable production, even with tight tolerances or complex moulds

The Roboshot also enables in-mould pressure control, allowing dynamic adjustments to pressure during packing and holding phases, which further improves quality.

Real-world impact: Fewer rejects, less downtime for quality inspections, lower scrap rates, and higher customer satisfaction.

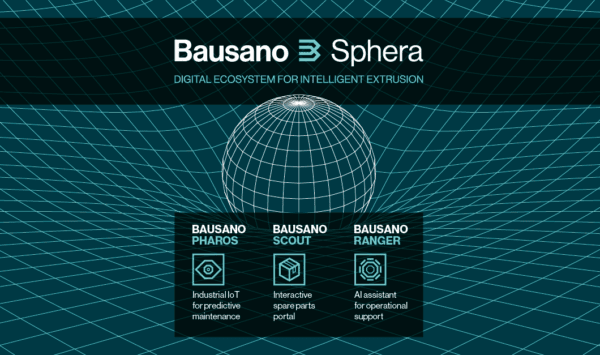

4. Smart Manufacturing and Predictive Maintenance

The Roboshot is fully prepared for Industry 4.0 integration and has been for a while. With built-in data connectivity, machine health diagnostics, and production tracking, it provides critical insights that drive smarter decision-making on the shop floor.

Digital Benefits:

- Remote monitoring: Using our own quality management tool; RoboshotLinki2, users can view real-time machine performance and output data from any device.

- Predictive maintenance: Built-in sensors track motor torque, injection force, and mechanical wear, alerting users before issues cause downtime.

- Production analytics: Log cycle times, rejection rates, and energy consumption for continuous improvement initiatives.

Real-world impact: Minimised unexpected downtime, optimised maintenance scheduling, and faster response to production issues.

5. Clean Operation

Hydraulic machines inherently require more upkeep due to fluid systems—leaks, filters, pumps, oil degradation. By comparison, the Roboshot offers clean, oil-free operation, making it ideal for medical moulding, food packaging, and cleanroom environments.

Benefits Include:

- No hydraulic oil leaks: Reduces risk of contamination and improves machine cleanliness.

- Less frequent maintenance: Fewer moving parts and no fluid circuits mean longer intervals between service.

- Lower operating noise: Roboshot runs at under 65 dB, improving factory floor conditions.

Real-world impact: Safer, cleaner production environments; reduced unplanned downtime; and lower long-term maintenance costs.

The Conclusion: Roboshot = Efficiency, Profitability, and Peace of Mind

The FANUC Roboshot is more than just a moulding machine—it’s an intelligent, efficient and cost-effective manufacturing platform. Whether you need faster cycle times, lower energy costs, improved part consistency, or smarter data integration, the Roboshot delivers across the board.

If you’re still running hydraulic machines—or even hybrids—you may be leaving efficiency and profit on the table…

*Written by Sam Carr

Read more news from FANUC here.

FANUC

+44 (0) 24 7605 3000

Website

Email