GETECHA Unveils Granulation Innovations at K 2025

|

Getting your Trinity Audio player ready...

|

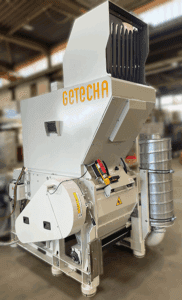

At this year’s K trade fair in Düsseldorf, GETECHA, distibuted in the UK via Labotek GB, is unveiling its latest advancements in granulation technology, including a standout innovation: the HHS feed system. Designed to eliminate the need for pre-shredding large hollow articles and slugs, this system streamlines plastics processing and will be demonstrated at GETECHA’s booth A09 in Hall 9 using the RS 38060 hopper granulator.

Visitors can explore a wide array of equipment, including infeed granulators for thermoforming skeleton film, guillotines for sheet extrusion edge trims, beside-the-press granulators for injection moulding, and foil cutters for low-dust edge trim processing. The centerpiece, however, is the HHS feed system, which features an intelligent metering pusher that adjusts feed based on rotor load and offers programmable control settings tailored to different materials.

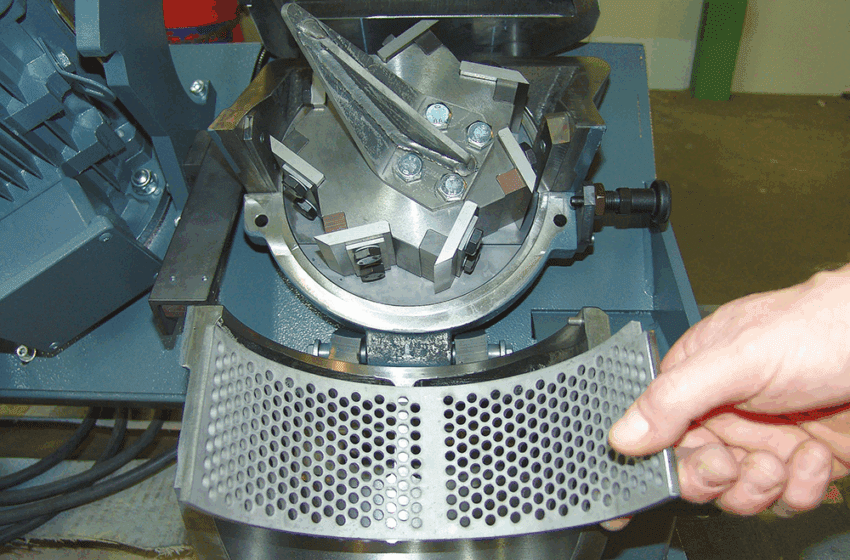

The RS 38060 granulator, powered by a 22kW motor and equipped with a hydraulic pusher, showcases the HHS system’s capabilities. It efficiently processes voluminous blow-moulded parts and slugs directly into granulate, bypassing the need for upstream shredders and conveyors. This results in reduced energy consumption, lower technical complexity, and significant time and space savings.

GETECHA’s commitment to quality is evident in the RS 38060’s robust construction and versatility. It handles sprues, packaging returns, film rolls, and solid plastic residues with ease. Its compact design supports modular upgrades such as discharge screws, control cameras, and water cooling. The smooth, enclosed cutting chamber geometry ensures easy cleaning and maintenance, while ergonomic and safety features enhance usability.

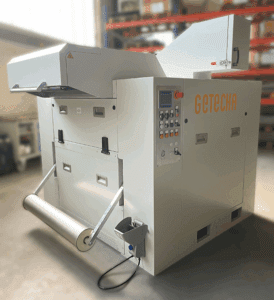

Also on display is the RS 30090-E infeed granulator, ideal for thermoforming applications. With a three-blade rotor, 22 kW drive, and self-adjusting dancer arm control, it processes skeleton film and unpunched parts. Optional speed-controlled feeders and dual hoppers allow for flexible reject collection. Sound insulation and water cooling make it suitable for thermosensitive plastics and close-to-line operation.

For injection moulding, GETECHA presents the GRS 180 beside-the-press granulator. With a 2.2 kW drive and throughput of up to 35 kg/h, it’s optimised for hygiene-sensitive environments thanks to its integrated extraction system and sealing technology. A double slide gate hopper ensures splash-free feeding, and optional carbide blade inserts enable grinding of abrasive materials.

Another highlight is the RS 150, introduced in 2024. This compact granulator handles sprues and defective parts via manual or automated feeding and delivers high-quality regrind for materials like TPE and POM. Adjustable feed heights and a horizontal rotor make it adaptable and space-efficient.

GETECHA’s portfolio also includes FS 200/FS 300 film cutters for ultra-thin edge trims and the GH 300 guillotine for extrusion applications, capable of pre-cutting thick POM and HDPE residues.

Beyond machinery, GETECHA supports full project implementation—from design to commissioning—offering tailored solutions for grinding, automation, and material handling. Their technical center enables practical testing, reinforcing their role as a comprehensive partner in plastics and recycling technology.

Read more news from Labotek here.

Labotek

+44 (0) 1564 822172

Website

Email