Getecha Granulation Technology Enables Recovery of Extrusion Waste

Represented by Labotek GB in the UK, granulator specialist Getecha recently helped a manufacturer of drive belts produce high-quality plastic granulate from the edge trims coming off its extrusion lines.

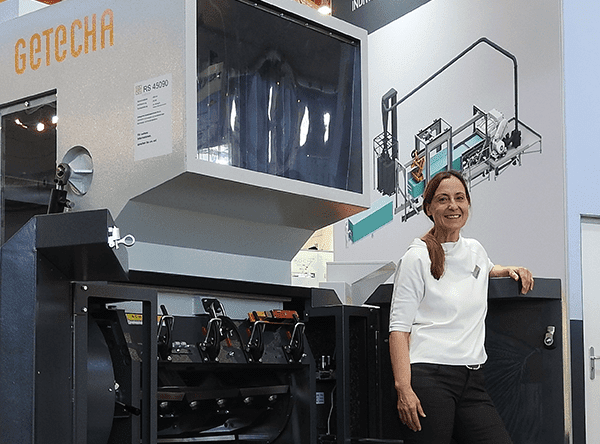

Eva Rosenberger (pictured), Sales Manager and shareholder at Getecha, said: “Whether it is during extrusion or assembly of foils, foams and panels – the continuous extraction of plastic granulate from edge trims provides plastics processors with an excellent opportunity to reduce their raw material, logistics and disposal costs.

“Reusing the recycled material had a positive effect on the production volume and yields, and the associated reduction of material loss contributes to the sustainability of the whole company.”

Working across granulation, handling and extraction systems designed by the company, which is based in Aschaffenburg in Germany, Eva is repeatedly involved in the implementation of numerous projects for the realisation of modern recovery and recycling solutions in the plastics industry.

Getecha recently took on the task from a reputable manufacturer of drive belts and conveyor belts that required granulators. In parallel to the cycling of the extrusion or assembly systems, they were expected to continuously and simultaneously pull in, granulate and provide two edge trims made of TPE or TPU 50-95 Shore A – occasionally also with integrated inlays made of steel – for further processing. This time, the infeed granulators of type RS 2402 E of the well-known RotoSchneider series from Getecha were chosen.

Eva commented: “This machine is part of a highly successful model series, which is perfectly adapted to the production of high-quality ground material, which can be recycled or added to the new material.”

Compact and customer-specific

As for many other projects of this kind, the system solution from Getecha, in this case, is also based on the application-specific customisation of a standard system. Adapted to the specific requirements of the drive and conveyor belt manufacturer, the RS 2402 E machines were equipped with 4kW drives, which provide the infeed granulators with granulation performance of up to 80kg of ground material per hour during running operation.

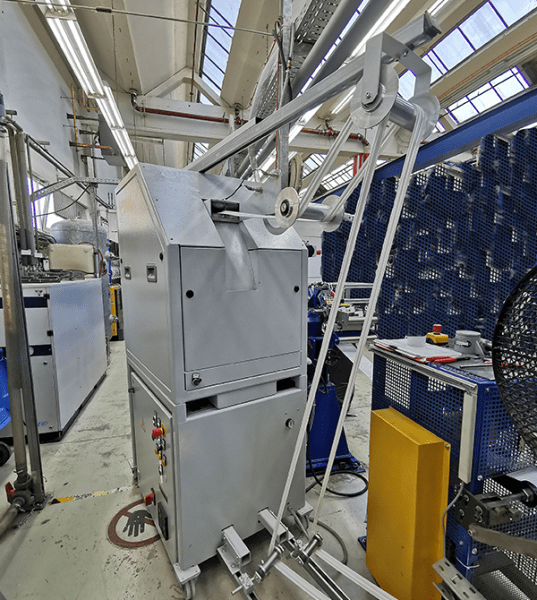

At the customer’s request, they also received sound-insulated, compact and stable machine frames with an integrated switching cabinet made mobile by guide rollers. With a slender design (750 x 1,970 x 1,810mm), they can be positioned space-efficiently directly next to the assembly or extrusion lines.

As it was necessary to feed the edge trims to be shredded from ground level, Getecha equipped the granulators with additional arms and pulleys.

Apart from the customer-specific modifications, the RS 2402 E from Getecha is characterised by a multitude of technical intricacies. For example, this includes the roller deflection with a floating roller of a dancer arm type, which ensures a particularly material-friendly pulling off of the edge trims from the trimming systems and compensates the traction and vibrations affecting the edge trims.

While two knurled infeed rollers inside the granulator also counteract the transmission of vibrations onto the edge trims, integrated sensors detect excessive traction and limit the infeed if there is a risk of tearing.

Furthermore, a two-part hopper in front of the infeed opening enables simultaneous feeding in of two edge trims into the roller infeed, without them crossing each other and getting tangled.

Ultimately, for the production of the drive and conveyor belt manufacturer, all these measures make sure that the edge trim infeed is efficient, practically trouble-free and always adapted to the speed of the extrusion or assembly system.

From ground material to reusable material

Eva commented: “The correct design of the granulation system and synchronisation of the infeed speed are key factors for its successful integration into the production environment. However, just as important are the customer’s requirements with regard to the quality of the ground material.”

For this reason, amongst others, the RS 2402 E has an intelligent control for regulating the infeed speeds, which also includes an automatic switch to buffer operation. When the minimum infeed speed is undercut, this control developed by Getecha prevents the generation of obstructive fine material and undesirable dust particles during granulation, thus ensuring that the granulator always produces clean ground material of excellent quality even with low infeed speeds in the range of 0 – 6.0 m/min.

Eva added: “This is achieved by automatically switching into buffer mode while simultaneously undercutting the optimum outfeed speed. The dancer arm is used as material storage here, and the infeed is activated and deactivated depending on the position of the dancer arm, which thus determines the storage volume.”

Quality from the first cut

In addition to the intelligent control and buffer operation, there are two additional factors with which the RS 2402 E provides the drive and conveyor belt manufacturer with high ground material quality: First of all, optimum ventilation of the ground material during the granulation process, preventing potential material heating, and supporting optimum material flow when processing elastic materials, even at larger quantities.

And secondly, the use of a very sturdy and openly designed three-knife-rotor with powerful cutting. It has a diameter of 240mm, provides a cutting length of 226mm and is equipped with blades of highly quenched and tempered carbide, which are characterised by excellent cutting capacity and long service life. In case the infeed of third-party material such as steel inlays cannot be excluded, blades of normal quality or high-speed steel (HSS) can also be inserted. As the fed-in edge trims are directly guided via the double roller infeed of the RS 2402 E between the rotor and stator blade, it is ensured that the best possible ground material geometry is produced with the first cut already.

Eva said: “This is an important technical prerequisite to achieving an excellent granulation performance and outstanding ground material quality.”

Sustainability

Through its use, a modern infeed granulator such as the RS 2402 E from Getecha contributes to the establishment of sustainable production methods in plastics processing and is itself a successful example of development and engineering, which is consistently based on the principles of sustainability and energy efficiency. The RotoSchneider rotary cutters from Getecha can be equipped with the innovative EnergySave system of the plant construction company, amongst others, which reduces its electrical energy consumption under partial load by up to 40%.

The high quality of the carbide blades from Getecha also contributes to lowering the operating and maintenance costs. The effort alone for replacing and regrinding the blades is thus significantly reduced. If filled plastics are granulated, required intervals for regrinding are significantly extended.

Economical complete solutions

With its broad range of granulators as part of the RotoSchneider line, as well as the guillotine shears of the GH series and the foil cutters of the FS series, Getecha provides extensive options for the realisation of modern system solutions for production-related material recovery at a scale between 10 and 5,000 kg/h.

The range of services offered by the plant construction company from Aschaffenburg also always includes the provision and customised design of conveying and suction technology for the feeding of edge trims, as well as collection and forwarding of the ground material. For example, in the case of the drive and conveyor belt manufacturer, it was discussed whether the ground material should be collected below the system following granulation, whether it should be extracted by suction by means of a suction conveyor on the customer side, or whether it should be forwarded to the place of further processing via an extraction system from Getecha.

Eva concluded: “In order to ensure the cost-effectiveness and efficiency of our complete solutions, a detailed requirement analysis is carried out for each project in advance, including a projected calculation for the costs and consumption.”

Labotek GB Limited represents Getecha Granulators in the UK. For more information on Getecha Granulators, contact Labotek GB Limited directly using the details listed below.

Labotek GB

+44 (0) 1564 822172

Website

Email