Great Central Plastics Blog // The Importance of Design for Manufacturability (DFM) in Injection Moulding

|

Getting your Trinity Audio player ready...

|

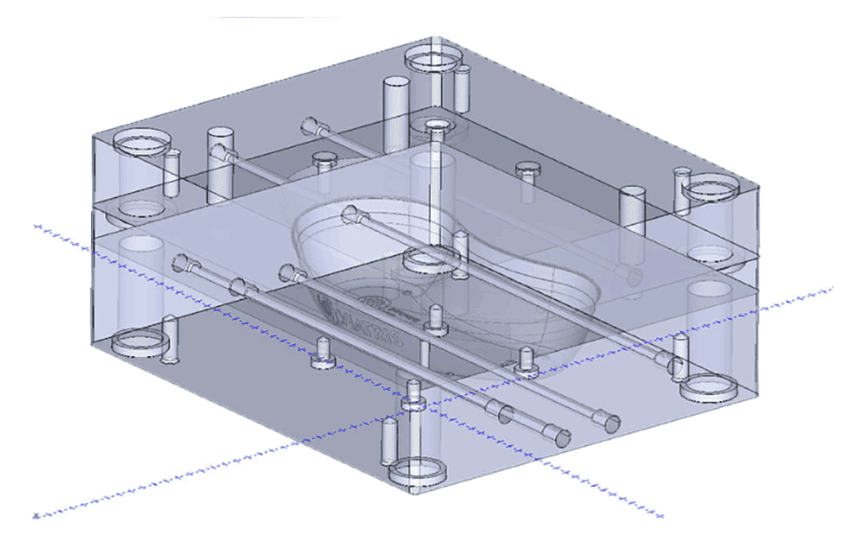

Designing a product for injection moulding involves far more than just achieving the desired shape or appearance. It’s about ensuring that every element of the design supports a smooth, efficient, and cost-effective injection moulding process once high-volume production begins. That’s where Design for Manufacturability (DFM) comes in. In this blog, Great Central Plastics explores how DFM principles enhance injection moulding efficiency, reduce costs, and improve product quality.

DFM is the practice of designing products to be manufactured easily and reliably, without unnecessary complexity or expense. In the context of plastic injection moulding, good DFM can help reduce waste, speed up production, and ensure consistent product quality, all while keeping tooling and unit costs under control.

Why DFM Matters in Injection Moulding

Injection moulding is a powerful process, ideal for producing large volumes of identical plastic parts. However, poor design decisions can lead to manufacturing defects, tooling complications, and longer cycle times, which are expensive and time-consuming to remedy further down the line.

Here’s why DFM is essential:

- Improved part quality: A design optimised for manufacturability results in stronger, more consistent parts, from the first production run.

- Lower production costs: Efficient designs reduce tooling time, minimise waste, and help shorten cycle times, lowering the cost of moulding every individual part.

- Quicker turnaround times: Simpler, well-thought-out designs allow for faster setup and fewer production delays further down the line.

- Longer tool life: Avoiding unnecessary features can reduce wear on mould tools and prevent damage.

By working with an experienced injection moulder early in the design process, you can avoid many common issues and ensure your product is ready for efficient mass production.

Key DFM Considerations for Injection Moulded Parts

1. Wall Thickness

Uniform wall thickness ensures even material flow and cooling of the polymer material within the mould. Inconsistent wall thickness on a plastic product can lead to defects like warping, sink marks, or voids. Where variation in wall thickness is unavoidable, transitions should be gradual to minimise stress.

2. Draft Angles

Adding draft angles (typically 1 to 2 degrees) to vertical walls helps release the part from the mould more easily. This reduces wear on tooling and lowers the risk of damaging parts during ejection, as well as improving cycle times.

3. Ribs and Bosses

Structural features such as ribs and bosses increase part strength without significantly increasing material usage. These should be carefully positioned and sized to avoid thick sections and improve mould filling.

4. Fillets and Radii

Sharp corners can cause stress concentrations and reduce mould tool life. Rounded edges improve flow, reduce the likelihood of cracking, and contribute to a more durable part.

5. Undercuts

Avoiding undercuts keeps the tool simple and cost-effective. Where undercuts are necessary, side actions or collapsible cores may be required, which increase tooling complexity and cost.

6. Gate Location

The gate is where molten plastic enters the mould cavity. Correct gate placement ensures proper filling, reduces visible marks, and avoids defects like air traps or weld lines.

7. Parting Line Position

The parting line is the plane where the two halves of the mould meet. Choosing a logical, unobtrusive position for this line can improve both appearance and function.

8. Material Selection

Material choice should align with the product’s end use. Different plastics behave differently during moulding and may require specific design tweaks to accommodate shrinkage, flow characteristics, or temperature resistance.

9. Tolerance Requirements

Clearly defined tolerances help avoid costly rework. However, overly tight tolerances can increase tool wear and production time. A good moulder will advise on what’s achievable without unnecessary expense.

How GCP Supports DFM in Every Project

At Great Central Plastics, we work closely with clients from the earliest design stages. Our team applies DFM principles to ensure every part is optimised for performance, cost, and quality. Whether we’re working from your existing CAD files or developing your product from scratch, our aim is to deliver parts that are right first time and ready for production.

We also offer in-house toolmaking, which means the same team responsible for your design is also responsible for building the tooling and manufacturing the parts. This joined-up approach reduces the chance of errors and ensures greater control over quality and lead times.

Final Thoughts

Design for Manufacturability is a critical part of any successful injection moulding project. Getting the design right at the start can save weeks of rework, thousands in tooling costs, and countless hours in production time.

Whether you’re developing a brand-new product or refining an existing one, GCP is here to help guide your design towards efficient, sustainable production. Contact our team to discuss your next project.

Read more news from Great Central Plastics here.

Great Central Plastics

+44 (0) 1327 264277

Website

Email