Gunther UK Successfully Implements Compact Valve Gate System

Gunther UK is proud to introduce a significant development in hot runner technology. In partnership with advanced tooling experts, the team has successfully implemented an exceptionally compact valve gate system that delivers 32 gates within a footprint of only 70 mm x 35 mm, setting a new benchmark for high-density injection moulding, particularly suited to the manufacture of parts like medical well plates, for example.

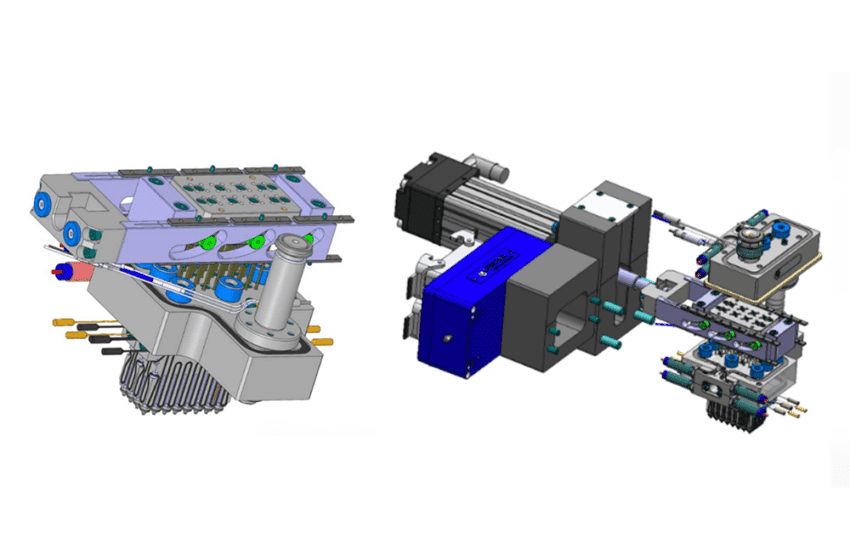

Electric Valve Gate System with Servo-Controlled Precision

At the heart of this innovation lies an electrically driven valve gate system. The precision servo actuator enables fine adjustment of the needle position with ease and consistency. A custom-engineered sliding plate with recirculating rollers provides targeted and robust force transmission, ensuring reliable closure of the valve pin precisely at each injection point. The synergy of these elements enhances both process stability and repeatability in large-volume production.

Engineered with flexibility in mind, the modular system can be scaled up to accommodate as many as 96 injection points, again on a very small footprint. This makes it an ideal choice for a wide variety of moulding applications, particularly where space is at a premium.

Optimised for Temperature and Flow Consistency

As always with Gunther, thermal control has been a critical focus of the development. Dedicated heating zones ensure uniform temperature across melt-flow areas, while the manifold’s optimised channel layout delivers balanced melt distribution – even in complex, multi-cavity configurations.

The high precision needle guide, also known as a PM insert, made from wear-resistant material, supports consistent gate quality, long-term durability and ease of maintenance. This is complemented by a temperature control concept co-developed with the tooling partner, achieving seamless integration between mould and hot runner components.

Redefining Precision for the UK Plastics Industry

Gunther UK’s latest advancement reaffirms its commitment to precision and innovation in injection moulding. By addressing the growing demand for compact, multi-cavity systems, this new hot runner solution is well-positioned to meet the exacting standards of manufacturers across the UK and Ireland.

For more information or technical enquiries, please contact Gunther UK – Reiner Heedeniya 01474 879774

Read more from GÜNTHER here.

Gunther UK Limited

01474 879774

Website

Email