Husky Unveils Next-Gen Packaging Moulding Platform at K 2025

|

Getting your Trinity Audio player ready...

|

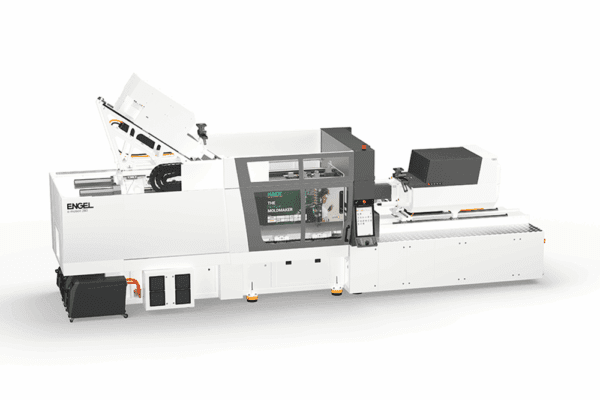

Built to work together as one seamless ecosystem. Designed to change everything. At K 2025, HUSKY is unveiling the exciting evolution of its next-generation Packaging moulding platform – high performance injection moulding system with a new look and feel, hot runner, mould controller, and now introducing its Advantage+Elite™ real-time, proactive, remote monitoring for Packaging.

- Enhanced energy efficiency: Servo-pump technology lowers consumption by 10% while dramatically reducing hydraulic requirements

- Perfect combination of speed and precision: Faster injection, higher pressure, optimised throughput, for even the most demanding applications

- Melt delivery perfected: Fully integrated melt stream delivery for consistent part quality and highly repeatable moulding processes

- Designed to unlock growth opportunities: Transformative new hot runner and controller expand design flexibility, and boost packaging manufacturing efficiency

- Connectivity that never sleeps: NEW Advantage+Elite™ for Packaging tracks 70 unique performance insights, turning data into your competitive edge

New Auxiliary Technology – Introducing Altanium MultiShot™

Including both injection units and rotary platen, the new MultiShot™ technology is a fully integrated, multi-material solution that improves manufacturing efficiency, performance, and flexibility. Enabling expanded moulding capability, the secondary injection unit and rotary platen technologies turn any single-barrel injection moulding machine into a multi-material injection moulding production cell.

Hot Runners and Mould Controllers – Powering Performance Across Industries

Engineered to deliver more than just melt flow. Designed to expand possibilities.

At KShow 2025, Husky is introducing its next generation hot runner and controller technologies, enabling customers in packaging, medical, personal, and home care markets to achieve greater efficiency, precision, and profitability.

- Next-level reliability: Ultra Helix Valve Gate technology delivers unmatched robustness, energy savings, and cycle consistency, to boost uptime and productivity.

- High-volume durability: Ultra SideGate™ Next Generation now supports up to 8-tip configurations. A compact mould design maximises cavitation and yields millions of cycles of repeatable performance.

- Smarter control, greater output: The new Altanium™ Neo6, Delta6, and Matrix6 controllers redefine precision and profitability, ensuring faster startups, superior resin protection, and optimised energy use.

Industry-leading Medical Solutions

When precision means everything, there’s no room for risk. The industry-leading medical solutions produce the devices that matter most, from pre-filled syringes to auto/pen-injectors, blood collection tubes to reaction cups, pipette tips to petri dishes, and more!

Discover how Husky’s integration with Schöttli’s proprietary gating technologies is opening new sectors and expanding possibilities across parenteral, diagnostics, and laboratory applications.

Why Visit Husky at KShow 2025?

At KShow 2025, Husky is pushing the boundaries of moulding to enable infinitely circular possibilities. Husky invites you to pre-book a meeting with a Husky expert at the show.

- Personal guided booth tour

- One-on-one expert consultations

- Product demonstrations

- Sustainability discussions

- Collaboration opportunities

Read more news on Husky here.

Husky

352 52 11 51

Website

Email