KraussMaffei at K 2022: Two Innovations for the Circular Economy

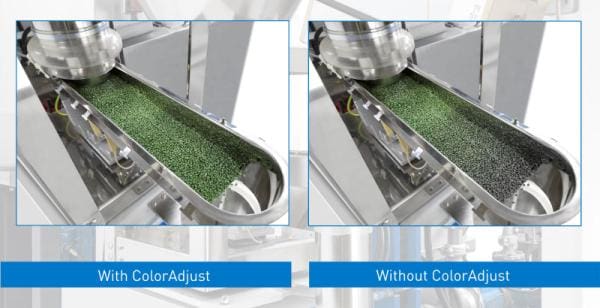

At the K Show 2022, KraussMaffei will present its latest developments in extrusion technology, with a focus on sustainability and the circular economy. Show visitors can observe the fully automatic colour correction process utilising KraussMaffei’s ColorAdjust, to ensure precise, reproducible colours during compounding.

The colour of an end product is now an important aspect of modern branding. With ColorAdjust from KraussMaffei, colour variations with input goods of different colours are a thing of the past. The innovative system combines a colour measuring device with photospectrometer technology and machine control to ensure precise, reproducible colours. Visitors can observe the fully automatic colour correction process at the K trade show booth C 24 to D 24 in Hall 15. In the CircularEconomy process on the booth, a twin-screw extruder compounds shredded medical caps into a fibre-reinforced, colour-precise recyclate.

The ColorAdjust solution developed by KraussMaffei is the first of its kind on the market. It is designed not only for contactless monitoring of colour variations, but to compensate even for minor deviations by directly adjusting the precise colour setpoint. This gives compound processors high reproducibility even when processing input materials of varying colour spectrum. The colour setpoint is rapidly achieved when starting the compounding process after a stop as well as in the event of colour changes.

In view of the fact that start-up scraps and reject material to be subsequently disposed of are thus minimised, ColorAdjust ensures the sustainable and highly efficient production of reclaim material. This will save not only time and money but above all, valuable raw materials.

Sustainable production with fully automatic colour correction during compounding

KraussMaffei’s ColorAdjust system comprises two units: A spectral photometer determines the colour of the cooled reclaimed pellets in the vibration chute and transmits the corresponding results to the machine control system. These values are used to control the colour metering unit that is equipped with at least four colours and four metering devices. Upon request, the system can be expanded to six colours to flexibly cover the entire colour spectrum that the human eye can distinguish. The colour can generally be added in masterbatch or liquid form.

The ColorAdjust system adjusts the colours fully automatically without any operator intervention. Thanks to its integration into the twin-screw extruder control system, it can be operated easily from the central control panel.

From insulin pen caps to automotive door modules: Follow the Circular Economy at first hand

At the KraussMaffei booth in Duesseldorf, interested visitors can get a live experience of the entire material cycle: from polypropylene virgin material used in the production process via re-compounding right through to the finished reclaimed material.

The PX 200-1400 injection moulding machine equipped with a 96-fold tool produces insulin pen caps from PP. On the downstream mill, these caps are subsequently shredded to regrind. The resulting reclaimed material is transferred by appropriate conveying systems into the ZE 28 BluePower twin-screw extruder in UltraGlide version with a processing section length of 44 D.

Thanks to the UltraGlide feature, the screws can be removed automatically from the processing section for cleaning purposes, while the extruder with its ideal ratio between screw volume and torque ensures optimum melt homogenisation and colour dispersion. Glass fibres and additives as required for applications in the automotive industry, for instance, can be incorporated via additional gravimetric loss-in-weight feeders.

Visit KraussMaffei at K 2022 in Hall 15, booth C15/C24-D24.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email