At K 2025, KraussMaffei Present “FrontIQ Light” Headlight Manufactured using ColorForm Technology

|

Getting your Trinity Audio player ready...

|

At K 2025, KraussMaffei, in collaboration with its partners LEONHARD KURZ and Rühl, will unveil the future of lighting technology. The “FrontIQ Light” combines design, function, and protection in a single, highly integrated manufacturing process. At its core is ColorForm technology, which utilises a precise polyurethane surface that is applied directly to thermoplastic components within the injection mould.

Conventional headlights require expensive hard coating. In contrast, the “FrontIQ Light” features an inline-applied PUR layer that protects against UV radiation, stone chips, and chemicals. The coating can be adjusted with precision to within a tenth of a millimetre. It enables variable haptic effects and even has a self-healing effect for fine scratches. “With our ColorForm technology, KraussMaffei is revolutionising front lights: from design freedom with printed films to precise 3D forming – all in one intelligently networked complete solution,” explains Dr. Frank Szimmat, Managing Director KraussMaffei Technologies.

Design freedom through film integration

What makes it special: The combination of several thermoplastics, decorative film, and PUR surface opens up almost unlimited design possibilities. Brilliant depth effects, individual patterns, and durable protection are created directly in the mould – without any subsequent painting processes. The surface is designed using films printed using thin-film technology, which are back-injected into the mould using a sheet-to-sheet process with transparent and black polycarbonate. “Automotive design today is more expressive and emotional than ever before. With concepts such as ”FrontIQ Light,” we are taking design to the next level – seamless, sustainable, and full of new possibilities. Light becomes a language. Surfaces become a brand experience,” says Luitpold Haarländer, Head of Sales Management Automotive at LEONHARD KURZ.

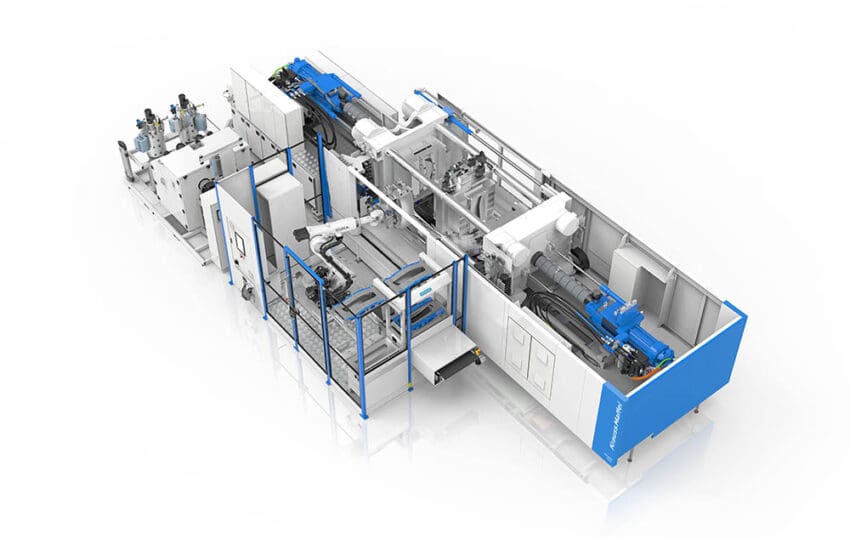

Turnkey complete solutions from a single source

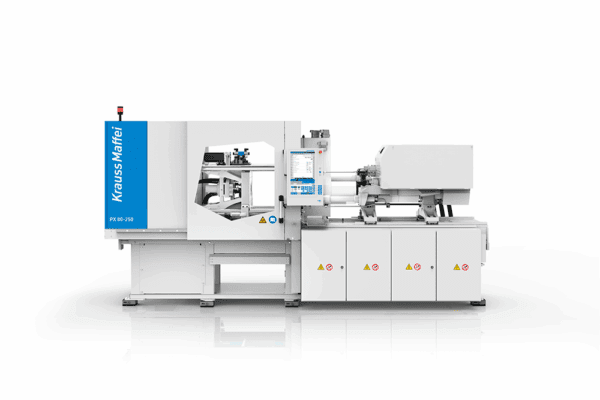

KraussMaffei supplies ColorForm technology as an integrated solution, covering automation, PUR technology, and injection moulding. The result is a fully integrated process: design, function, and protective layer are created directly in the mould without any additional reworking.

At K 2025, visitors can experience the technology live on a GXW 650 with a reversible plate. A 3K demonstrator in the design of a 720-millimetre-long headlight will be on display at the LEONHARD KURZ booth in Hall 5, A19.

Read more news from KraussMaffei here.