Labotek Showcases Energy-Efficient Innovations at K 2025

|

Getting your Trinity Audio player ready...

|

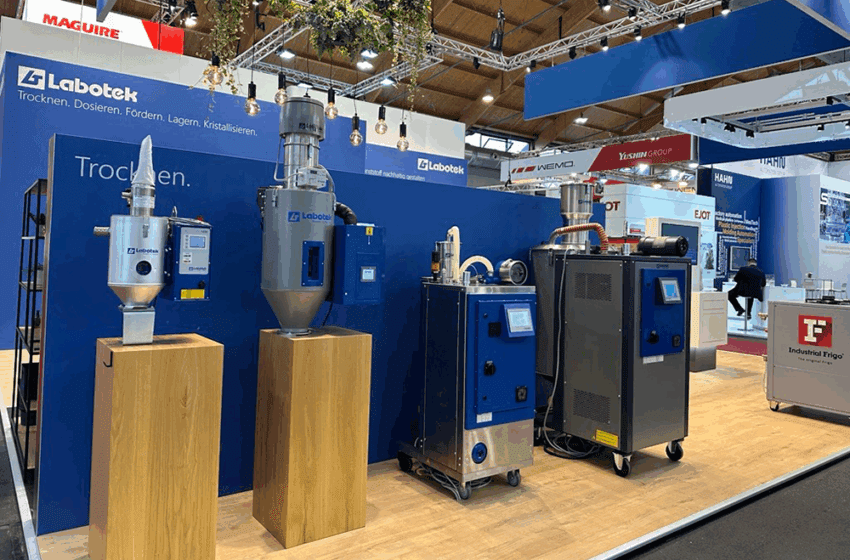

With a comprehensive portfolio of technological innovations, Labotek will present pioneering solutions for resource-efficient, flexible, and cost-effective plastics processing at this year’s K trade fair in Düsseldorf. Key highlights include new drying and control systems, smart energy concepts such as External Heat Recovery (EHR), and digital tools for process optimisation.

“In a time when efficiency, sustainability, and quality set the pace, our technologies help position production processes to be both economically viable and future-proof,” emphasise Managing Directors Thomas Ringheim and Lukas Pawelczyk.

“Our systems are specifically designed to significantly reduce energy consumption and operating costs – while providing maximum transparency and traceability of all relevant process data via our Labo-Net control system. This creates the foundation for efficient, safe, and economically sustainable production processes.”

Precision Meets Drying: Labotek and Movacolor Present the MDS Balance Drydose

Labotek and Movacolor have combined their expertise to jointly develop an innovative solution for drying and dosing additives: the MDS Balance Drydose. For the first time, the newly developed system integrates highly efficient material drying with precise additive dosing – in a single compact unit. This sets new standards in plastics processing, providing a unique answer to the industry’s increasing demands.

The growing demand for bio-based materials, highly specialised engineering plastics, and increasingly stringent quality requirements calls for new approaches to material preparation. This is where the Drydose comes in: it delivers targeted, on-demand additive drying and plays a key role in minimising quality risks.

A major advantage of the system is its ability to dry the material directly within the dosing station at the machine feed – eliminating the need for additional drying units. This integration not only ensures consistently optimal drying but also improves product quality and reduces scrap. The result: a significant increase in overall production efficiency.

“Since installing the MDS Balance Drydose, streaking in our additive usage has become a thing of the past!” Bernd Wilming, Production Manager, agathon GmbH

Bottle-to-Bottle Concept

Globally, around 500–600 billion PET bottles are produced and consumed each year – equivalent to approximately 25–30 million tonnes of PET raw material. But what happens to the bottles after use? Only 10–20% are recycled – and crystallisation plays a central role in this process.

After collection and cleaning, the bottles are shredded into PET flakes. Before they can be further processed, the flakes must be dried. Since these flakes are typically amorphous PET – material with disordered molecular chains – direct drying is not possible. Only through crystallisation, where the molecular chains become ordered, does the material become heat-resistant, stiffer, and more opaque, making it suitable for thermal drying and further processing. Crystallisation is therefore a key step in achieving the bottle-to-bottle recycling principle.

To carry out this essential process efficiently, energy-optimally, and reliably, we are presenting our new solution for continuous PET crystallisation at K 2025.

With a focus on compact design, process stability, and high material flexibility, our system provides a convincing answer to the needs of the modern plastics circular economy.

EHR – External Heat Recovery

EHR stands for External Heat Recovery. But what exactly does this mean?

Unlike internal recovery systems, EHR harnesses waste heat from external sources such as compressor cooling systems or other industrial processes within the plant. The energy provided via hot water is fed directly into the process air of Labotek drying systems through highly efficient air-to-water heat exchangers.

Depending on the temperature and water flow rate, electricity savings of up to 85% are possible – a substantial contribution to CO₂ reduction and operating cost optimisation. Integration of EHR requires connection to a PLC control system – either directly via the control unit of a Labotek dryer or via our Labo-Net PLC. With the introduction of our new control concept, EHR can also be operated as a stand-alone unit – flexible and manufacturer-independent.

New LCD

The Labotek Compressed Air Dryer (LCD) is ideal for smaller applications, such as injection moulding machines, where the material to be dried does not require an extremely low residual moisture content.

As is well known, compressed air is one of the most expensive utilities in industrial production. Nevertheless, there is an economic threshold up to which the use of a compressed air dryer can be energetically and economically advantageous compared to dry air dryers – particularly when considering the energy required to heat the elements in dry air dryers.

This break-even point is around a material volume of 15 liters. For this reason, Labotek offers the LCD exclusively with 5- and 15-liter container volumes – a deliberate choice in favor of energy efficiency in the lower performance range.

For larger material quantities, we recommend using a dry air dryer such as the LRD with rotor dryer technology, or alternatively a mobile dryer from the DDM or DMR series, depending on the requirements and plant size.

The LCD’s microprocessor control is particularly user-friendly, allowing for safe and quick settings thanks to freely editable, pre-configured main materials. The airflow is continuously adjusted according to throughput and material type, and in combination with the integrated over-drying protection, energy consumption is significantly reduced.

Also new is the availability of an Android app that allows the LCD to be configured easily, intuitively, and on the go – ideal for flexible use in dynamic production environments.

Gravi-Dryer®

The demands on the plastics processing industry are constantly increasing – both in terms of energy efficiency and in terms of traceability and process reliability. Modern drying systems must now do far more than simply remove moisture from plastic granules.

Labotek’s DFD series offers a range of energy-optimised dry air systems, with capacities from 100 m³/h to 8,500 m³/h. The associated drying bins range from 15 liters to 12,000 liters, making them suitable for both decentralised use at individual processing machines and for central material supply systems.

The primary goal: continuous, stable drying with minimal energy input, adapted to actual material demand – without production interruptions.

At the heart of the system architecture is the Gravi-Dryer®, a gravimetrically controlled drying bin that precisely records material inflow and outflow according to the gain-in-weight/loss-in-weight principle. This continuous throughput measurement allows the system to dynamically adjust drying time to the actual material throughput – regardless of bulk density. The result: gentle, material-specific drying without the risk of over- or under-drying.

At the start of production, material flow can be ramped up either gently or quickly, and at the end of production, it can be gradually reduced. This avoids material losses and thermal overloading of the plastic granules – a common cause of quality issues during further processing.

Another efficiency benefit comes from the individual airflow control for each drying bin: only as much dry air is supplied as is needed for safe drying. The central dry air unit automatically adjusts to the air demand of the connected bins via frequency-controlled blowers.

Use of the Gravi-Dryer® functionality requires the Labo-Net control system, which records, manages, and visualises all relevant drying parameters.

Optionally, all material and process data can be fully documented – an important prerequisite for modern material and quality management in line with current industry standards.

New Control Concept

With the introduction of our new control concept, we present an innovative solution that significantly simplifies the setup, configuration, and expansion of systems. The control solution is designed for the DFD (dry air generator), DH (drying bin), SVS (vacuum station), and EHR (heat exchanger for external heat recovery) series, enabling a modular and flexible plant layout.

The central control element is a 10-inch touch panel integrated into the DFD. Up to 14 local units – consisting of DH, SVS, and EHR modules – can be operated via this central panel. Each unit is equipped with its own control system, including a 7-inch touch panel, and interconnected via continuous ProfiNet connections.

Networking is implemented in a continuous cascade from control to control, significantly reducing cabling effort and simplifying system integration. The scanning vacuum receivers (SVR) at the processing machines are also integrated into the system via their own control unit with eight outputs via ProfiNet. However, the individual SVRs are connected to this control unit conventionally.

The system also enables the integration of load cells beneath the drying hoppers, allowing weight data to be recorded and displayed both centrally via the DFD control and locally on the respective DH control. The Gravi-Dryer functionality continues to require the Labo-Net control system.

Thanks to its modular design, expanding existing systems is straightforward: new machines are connected to the existing system via ProfiNet cables, and the central control automatically detects and integrates the new units.

The new control concept is fully compatible with the proven Labo-Net control system. In this operating mode, the Labo-Net control takes over as the main central control unit.

Depending on the system configuration, the Labo-Net control can manage up to three DFD units, five SVS vacuum stations, and 40 DH bins.

Visitors to K 2025 can find Labotek in Hall 10, Stand B12 – where they can experience first hand how intelligent drying and control solutions pave the way for energy-efficient, transparent, and future-proof plastics production.

Read more news from Labotek here.

Labotek

+44 (0) 1564 822172

Website

Email