Injection moulding is a complex system of machinery, fluid dynamics, and thermal conductivity. Let’s break the mould down into two simple parts, the heat exchanger and the pressure vessel, and review how they can impact overall part quality and dimensions.

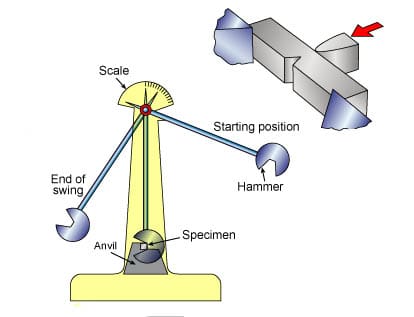

Falling weight impact tests can yield much more relevant information than single-point impact testing; however, they come with their own Read More

Cracking of plastics components under impact was a major blow to the plastics industry in the early days. Today it Read More

Injection moulding is one of the most commonly used methods of producing identical plastic products in high volumes. However, as Read More

From 3D Printing to CNC Machining, Vacuum Casting to Injection Moulding, the process options for plastic parts are limitless. Transitioning Read More

Low-cost identification of plastics is certainly desirable, but identifying an unknown plastic material can be an expensive exercise if you Read More

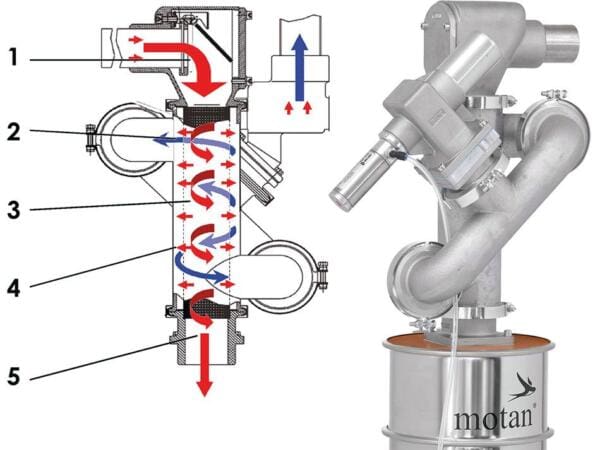

Mo explains the dedusting units and implosion purging of filters…Read More

Radiation in the ultraviolet region of the spectrum is a bit of a mixed blessing for polymers.Read More

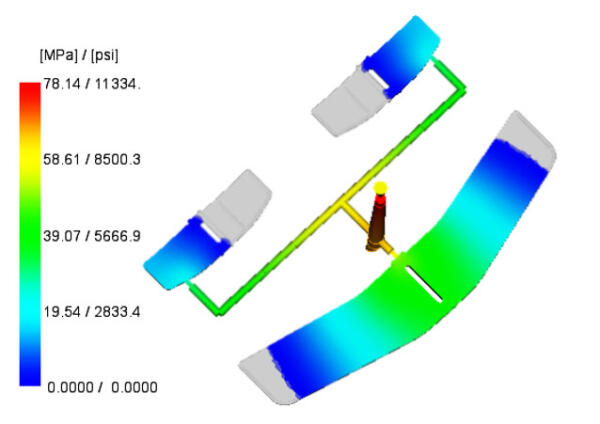

Moldflow software allows the flow of plastic inside a mould tool during the injection moulding process to be analysed. The 3Read More

Our next stop was at Telford based LVS Quality Measurement Services.Read More

Recent Posts

- Additive Manufacturing 181

- Auxiliary Equipment 401

- Case Studies 71

- Digitalisation & Industry 4.0 56

- Industry Updates & Events 424

- Material Handling & Temperature Control 246

- Plastic Materials & Additives 733

- Plastic Processing Machinery 912

- Plastic Processors 588

- Plastic Recycling & Sustainability 328

- PlastikCity on Tour 33

- PlastikMedia HotSeat 109

- Robots & Automation 254

- Service Providers 600

- Toolmakers & Mould Components 233