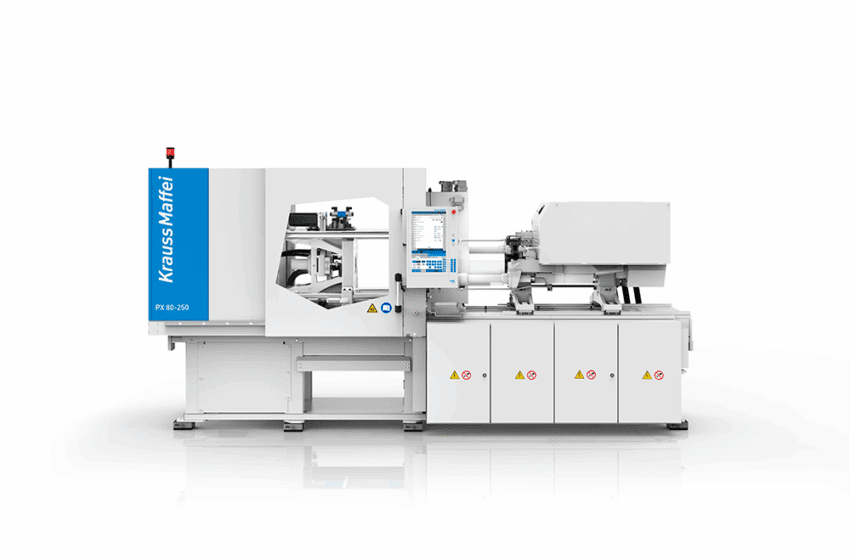

New All-Electric PX Series from KraussMaffei

|

Getting your Trinity Audio player ready...

|

From technical components to medical technology and packaging: all-electric injection moulding machines are gaining ground in all industries worldwide. KraussMaffei has completely redesigned its well-known PX series and will launch it at K 2025 with clamping forces ranging from 800 to 2,000 kN.

“It is the most modern all-electric injection moulding machine in the world. We have made it more compact, more productive, and more sustainable from the ground up.” Jörg Stech, Chairman of the Management Board of KraussMaffei Technologies GmbH, is proud of the new PX. The development team achieved this through a new structural design with optimized arrangement of individual components, new servo drive technology with electric ejector, and a modular, space-saving enclosure.

Key success factors of the previous PX series have been retained. The particularly large tie-bar spacing continues to allow the use of complex and heavy moulds. The wide support of the movable clamping plate guarantees perfect plate parallelism, and the linear guide ensures precise, energy-efficient movements. Energy recovery (recuperation) also remains an integral part of the PX series, as does high flexibility for a wide range of industrial applications.

World premiere at K 2025: The new all-electric PX series with new MC7 control system from KraussMaffei sets new standards in terms of productivity, cost efficiency, sustainability, and safety.

More speed, less energy consumption

All main axes and the new ejector are servo-electric. This not only improves cycle performance in the new PX, but also reduces energy consumption by around 20 percent. For energy-efficient movement of mould core functions and cascades, the PX can be optionally equipped with a compact, servo-hydraulic auxiliary unit. Thanks to the space-saving design of the drive components and optimized machine topology, the machine bed has been shortened. In combination with the slimmer housing, this results in a 20 percent reduction in footprint.

Optimized mould temperature control and digital hot runner control

The options for mould cooling and temperature control have been extensively revised, for example through direct water distribution to the clamping plates. The reduced pressure loss allows the use of smaller temperature control units, which is an additional efficiency advantage. Customers benefit from a wide range of temperature control solutions: from simple designs to digital single-circuit monitoring.

With the new KraussMaffei hot runner control, overall productivity can be significantly increased thanks to digital functions such as booster mode, fault detection, and other smart features.

New MC7 control generation: More performance, more ease of use

The PX marks the launch of the new MC7 control system—a modern, web-based platform with intuitive operation, powerful architecture, and the highest safety standards. It already meets the future requirements of the Cyber Resilience Act (CRA), offering increased protection against cyberattacks and enabling seamless digital connection of the machine. The new, web-based visualization concept impresses with its intuitive user guidance, clear display, and extended functionality. The interface facilitates setup, operation, and maintenance and increases efficiency in everyday production.

Visitors to the K trade fair can experience the performance of the new PX live at the KraussMaffei booth.

Perfection in the smallest of spaces: PX 80 as a production cell for technical applications

The new PX 80 with a clamping force of 800 kN impresses visitors to the KraussMaffei booth as a compact and economical solution for the production of technical components. The PX 80 production cell uses a mould from Wieland Electronic to produce electronic components made of polyamide. An LRXplus linear robot removes the components and places them on an integrated conveyor belt inside the machine enclosure. The CE-compliant system enables significantly higher production density: instead of four machines with linear robots, five systems can be operated in the same space.

Live at K 2025: A PX 80 manufactures electronic components from polyamide, underlining its strengths as an economical solution for producing technical components in the smallest of spaces.

PX 200 in cleanroom design produces medical components on a compact footprint

96 inner needle protection caps for insulin pens in just 4.5 seconds: the fast PX 200 for medical technology and a high-performance mould from KEBO AG make it possible. The PX is characterized by its high flexibility for use in clean rooms. Laminar flow boxes and conveyor belts can be easily integrated thanks to the modular enclosure concept – ideal for the demanding production requirements of the medical and pharmaceutical industries. With precision, productivity, and sustainability in a small footprint, this application demonstrates how the new fully electric PX is ideally suited for component manufacturing in cleanrooms.

Compact, fast, cleanroom-compatible: A PX 200 produces 96 inner needle protection caps for insulin pens in just 4.5 seconds at the KraussMaffei booth – perfect for the requirements of the medical and pharmaceutical industries

With the new all-electric PX series, KraussMaffei offers its customers real added value: lower operating and energy costs, higher productivity, and maximum flexibility with minimal space requirements. KraussMaffei thus provides a future-proof and sustainable solution that is perfectly tailored to the requirements of modern manufacturing companies.

KraussMaffei at K 2025

Hall 15, Booth C24

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email