In this case study, the Plasticom Group, a high-quality toolmaking and moulding business based in Kent, detail the development and manufacture of an innovative electrical fire safety component.

Background

Fires caused by high temperatures from faulty wiring is a major concern for householders and businesses alike. In England alone, there are more than 6000 fires per year associated with electrical distribution. The problems of plant breakdown due to overheated electrical connections are also well known throughout manufacturing industries and cause expensive disruption.

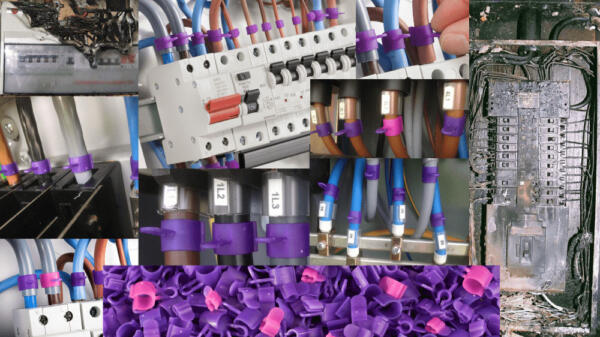

Safe Connect is an innovative electrical fire safety company specialising in creating products that can be used as an early warning indication to highlight heated electrical connections and circuits overloads without the need for thermal imaging cameras.

Safe Connect’s high quality and unique products highlight heated electrical connections and equipment to the naked eye by colour change. They give 24/7 monitoring and permanent colour change providing distinct benefits over conventional periodic visual or thermal camera inspections of electrical installations.

The push-on or self-adhesive applications make Safe Connect products quick and easy to install retrospectively into existing electrical installations or included in new installations.

The Challenge

During the development of these award-winning products, Safe Connect teamed up with Plasticom, a quality tool making, and plastic moulding business based in Ashford, Kent. The challenge was to create a product that would change colour when hot and stay changed so that problems would be highlighted to the viewer.

At the time, colour changing plastic materials were already available but would revert back to original colour when cooled down. So, the technology to make the colour change permanent also had to be developed.

The Plasticom service in action

During the prototyping stage, Plasticom worked with the Safe Connect team to create a design that would be easily clipped on to cables and then the be visible to the installer. Having agreed on successful product design, Plasticom used their extensive knowledge and experience to research the market to identify materials and masterbatches that would deliver the unique demanding specification of this product.

Using their in-house facilities, Plasticom built the moulding tools and moulded the cable clips supplying Safe Connect with the high-quality moulded products, delivered on time.

Positive results

Three designs of cable clip were created for use on cables ranging from 1 mm2 to 70mm2, giving a visual colour change if the cable has reached a predetermined temperature. Creative design, great teamwork, a problem-solving approach, high-quality tool making and moulding Safe Connects groundbreaking products have gone on to win industry awards 2 years in a row.

Please see https://www.safe-connect.co.uk/ for more information.

About Plasticom

Plasticom is a quality plastic moulding and toolmaking business based in Ashford, Kent. They are uniquely placed to offer you first-class service.

- High quality, up to date moulding equipment.

- In house toolmaking to provide fast, high quality and seamless service.

- Specialist medical experience and certification.

- Dedicated cleanroom facility.

- A problem solving, solutions and partnering approach focused on improving your business.

- Just in time supply and local to you to help reduce your costs.

- Unique biodegradable materials.

- ISO 13485:2016