PlastikCity on Tour – Intouch Monitoring

Our next stop was in the beautiful Northamptonshire countryside to visit Intouch Monitoring. We met with Sales and Marketing Lead Nathan Clarke, and BD and Marketing Lead, Sarah White, to discuss Intouch’s market-leading production monitoring and MES system, which has been improving efficiencies for manufacturers for over 25 years.

Intouch Monitoring is one of the leading and earliest providers of MES (manufacturing execution system) software to the UK industry since its foundation in 1997. Fast forward to today, Intouch has over 300 systems installed worldwide, increasing efficiency in a variety of manufacturing industries.

We caught up with Nathan Clarke and Sarah White at the company HQ in Northamptonshire to discuss the company’s history, plans for this year, goals for the future, and to chat all things production software!

The Founding Principles

The origin story for Intouch Monitoring is a classic one of entrepreneurship, engineering and creating a product to fill an existing need when one didn’t exist on the market. The company was founded in 1997 by John Hardwick and Karl Edwin, while John was working as a supply chain manager at a plastics injection moulding company. Frustrated with a lack of shop floor visibility and wasting time recording and analysing paper records (which often turned out to be inaccurate!) John turned to his childhood friend and electronic engineer, Karl, to develop their own custom solution.

“Like many businesses, Intouch was formed during a conversation over a drink in my local!” – John Hardwick, Managing Director.

The brief was simple, John wanted accurate production data, visible in real-time, enabling him to make informed time and cost-saving production decisions. While some systems existed on the market at the time, they were too complicated, expensive and inflexible, so the pair set about creating their own.

The result was Intouch Monitoring, an easy-to-use production monitoring software package that not only provides the useful benefits of the existing, higher-priced systems but also has the flexibility required by many manufacturers. John became Managing Director, and Karl, as Technical Director, became the principal architect and programmer of the Intouch system ever since.

Intouch‘s first customer, Superfos Packaging, continues to use Intouch software across its plants in Europe and the US, proving that over the 25 years of use, Intouch has continued to evolve and develop to the latest needs of its manufacturing customers.

Today, Intouch is one of the most widely recognised names in the MES arena, with a host of clients operating worldwide in various production environments. The Intouch team continues to grow, with a friendly and knowledgeable team with a diverse range of specialities and skills, ranging from coding and application development to sales, customer support and project management. Impressively, all software development and technical support is handled in-house, so customers are never too far away from the team that not only knows the system inside out, but likely helped to develop it themselves!

It was clear from our morning at the Intouch offices that the working environment is lively, friendly and energetic, with a great working buzz and passion tangible in the air, as the different teams studiously typed, tapped and chatted away with customers and contacts. A special mention goes to office dog Woody who certainly gave us the warmest welcome, and to the wider team for such a friendly and welcoming reception!

Now caught up on the company’s history, we sat down with Nathan and Sarah to find out what has set Intouch apart from its competition and provided 25 years of success in the sector.

Firstly, what is an MES System? Why should I invest in Intouch?

Nathan: “An MES, or Manufacturing Execution System, is a comprehensive software system that monitors and manages the manufacturing processes on a factory’s shop floor in real-time. Providing unparalleled visibility into every step of the production process, an MES system facilitates informed decision-making, enhances productivity, reduces energy usage, and drives operational efficiency.

“In the plastic moulding industry, an MES plays a multifaceted role. Beyond monitoring and managing machines on the shop floor, an MES aids in tracking and tracing raw materials to finished goods, scheduling machine usage for optimal efficiency, and maintaining quality control throughout the production process.”

Sarah: “The Intouch system gives you instant access to your real-time production data at any time, and from any device, eliminating the need for time-consuming and error-prone manual checks and processes. Our systems are flexible and scalable, meaning we’ll have a solution for businesses of all sizes in a variety of sectors.”

Nathan: “We know it can be frustrating for manufacturers to waste time and money sorting through out-of-date or inaccurate information, manually checking machine records and audit trails. Our software is designed with ease of use and flexibility at its core, and the increased visibility afforded through our dashboards allows our customers to anticipate changes, identify inefficiencies, proactively respond to alerts and make more informed business decisions, ultimately enabling them to become more productive and more profitable.”

What are your key products? How does this flexibility work in practice?

Nathan: “Our main product is the Intouch i4 Cloud system, which is our subscription-based model, where customers pay a fixed monthly cost per machine monitored. This simple model allows full transparency in costings, and we encourage prospects to try out the price calculator and ROI calculator tools on our website to visualise the potential costs and resulting savings for their own business.

“The Intouch Cloud system comes with three core modules, monitoring, scheduling and reporting, which form the core of the Intouch system. The core systems allow instant visibility, allowing production planners to instantly answer questions such as:

- Are my machines running, or have any stopped?

- What is the current cycle time? Is this output speed acceptable?

- How much material has been used? How much is still needed?

- How much labour am I using? Is this correct, or can it be fine-tuned?

- How many parts have been produced? How many have yet to be produced?

- When will this job be finished? When will the machine be available for the next job?

“For improving manufacturing efficiencies, knowledge is power and instant access to this information allows production staff to use their time more efficiently and be informed and motivated to keep machines operational and efficient.

“Our dynamic and intuitive dashboards can be customised and individually configured to suit your business needs, allowing you to see the data you need to make informed, quick decisions. All production data is recorded and archived, so you can look back at specific time periods, compare quarters, and analyse KPIs for a specific machine, tool or operator.”

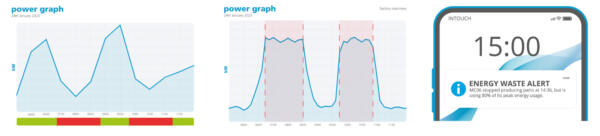

Sarah: “We also are developing additional add-ons for the core modules, with our recently launched energy-efficiency module aiding manufacturers in tracing, understanding and reducing their energy usage, at a time when energy prices are putting particular strain on the industry. This module includes energy wastage alerts, peak load analysis and real-time energy tracing to enable you to develop strategies to further reduce your operating costs. Our add-on modules can be added for only a few additional pounds per machine.”

What is your target market? Is your system targeted to a particular sector or company size?

Nathan: “Our origins are with plastic moulding companies, but our software is sector agnostic, so we also have customers across a wide range of manufacturing disciplines, from, food production and packaging to metal fabrication, medical devices and beyond. However, the software was initially designed specifically for the needs of plastic processors, which means we have a strong affiliation with the sector, and a large number of our customers operate in the sector too.

“We are a UK-based company, so naturally, we have many customers in the UK and Europe, but we operate globally, and we’re thrilled to be growing in the US. The beauty of our system is that it can scale to meet the needs of any business and works with any factory floor machinery – new and old. We have customers monitoring just a handful of machines, and some with entire fleets of dozens of machines and connected ancillaries.

“Regardless of the size of your operation, your manufacturing process will benefit from added levels of visibility and efficiency that the Intouch system provides. We are honest about our claims, with Intouch customers generally seeing an increase in OEE of between 6 and 30%.”

With lots of MES systems on the market today, why Intouch? What sets you apart from the competition?

Nathan: “Yes, there have been new entrants to the market in recent years, but we have a few advantages we think set us apart.

“Firstly, our system is designed from the ground up to work with plastics manufacturing companies. While applicable in other areas of industry, plastic processing was the primary focus throughout the development of the Intouch system and has all of the necessary features to support a plastics manufacturing operation. Intouch was designed by plastics engineers, to meet the specific needs of an injection moulding company and puts flexibility and intuitive ease of use at the top of the agenda.

“Secondly, is the strength of our team and our customer service. With over 25 years in the UK market, our team knows a thing or two about implementing and supporting customers in their digitisation journey. We provide full training and set-up for all customers, who receive all of the benefits of the system as soon as it is set up, with a new customer able to get up and running in as little as one week. We’re also all friendly, contactable and available, which we think is vitally important to creating close working relationships and creating accountability with our customers. We regularly attend industry events, trade shows, and networking events and would welcome any opportunity to discuss how Intouch could work for your company.

“Personally, I see this every day. Our customer retention is incredible with over 95% of customers staying with us year on year, and that’s definitely something to shout about.

“We also offer a free 60-day trial, which is a great way to ‘try before you buy’. And two months really gives customers a chance to put us to the test and see how our system can really benefit them. We do find that once customers are using the Intouch system, they rarely change. Many of our customers have been so delighted with the Intouch system, they are happy to tell others. We have many case studies and customer testimonials on our website from leading UK plastics processors, meaning we’re a name you can trust, and that will be here for decades to come!”

What plans does Intouch have for the rest of the year?

Sarah: “Since our energy-efficiency module launched at the start of 2023, we’ll be promoting the benefits this can bring at a variety of industry events this year. We exhibited at Sustainable Plastics Live in May, will be at the BPF Productivity Seminar in June, and at the NEC in September for Interplas 2023.”

Nathan: “We’re also working on new addon modules, but we’re not quite ready to talk in more detail yet. Watch this space!“

Do you have an official or unofficial company philosophy or mantra?

Nathan: “We talk internally about the ‘Intouch personality’ which is a way of thinking that we all aspire to follow every day. It includes being proactive, positive, and acting ethically and with transparency while working hard and always chasing innovation.”

Sarah: “We also use the phrase “Tech and Talent”, which I think encompasses Intouch perfectly. We’re working with the latest technology, which we’re improving and innovating on all the time, and coupled with our fantastic and knowledgeable team, creates an industry-leading company and MES system!“

Thank you to Nathan, Sarah, and the Intouch team for their hospitality and for providing a fascinating insight into the world of manufacturing software! If you want to improve efficiency in your plastics industry business, why not inquire about Intouch’s 60-day free trial?

Look out for the next edition of ‘PlastikCity on Tour‘ to learn more about our excellent UK-based partners.

There are now well over 260 active partners represented on the PlastikCity site, many of which offer highly specialised products or services to our sector.

During our everyday course of business, we’ll be making a point of visiting as many of these partners as we can and using the time to better understand what they offer the market. We’ll then showcase them through this ongoing series of articles.

Maybe you can benefit from their services!

Read more news from Intouch here.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email