PlastikCity on Tour: OMS LubriTek

Our latest stop took us to West Yorkshire to meet the team behind OMS LubriTek – specialists in oil management services for the plastics manufacturing industry. While the business was established in 2016, the depth of experience within the team goes back much further. Since then, OMS LubriTek has steadily gained a reputation as the go-to provider for proactive, data-driven oil management solutions in sectors where hydraulic oil performance is critical.

We were welcomed to OMS LubriTek’s recently expanded premises in Brighouse, West Yorkshire, by Jamie Shaw, who offered an in-depth look at how the company supports customers across the plastics supply chain – from OEMs and machinery suppliers to end-user manufacturers. The visit also included a tour of their facilities, showcasing the bespoke filtration rigs and diagnostic tools that underpin OMS’s nationwide service.

Background and Philosophy

Born from a desire to improve the way lubricants are used and managed within industrial machinery, OMS LubriTek was built on the principle that hydraulic oil should be treated as a vital machine asset, not just a consumable. As Jamie explained, “You wouldn’t ignore the quality of fuel, or not check the motor oil going into a high-performance car engine – the same should apply to oil in hydraulic systems.”

From the outset, the company has focused on education, technical performance, and delivering measurable improvements to customer operations. This approach saw OMS become a Plastics Industry Awards finalist in 2017, just a year after founding, a testament to its growing role within the sector.

Founded by Jamie Shaw in 2016, the team has significant experience in the oils and lubricants markets, with Jamie having over twenty years, and UK Service Manager, Stuart Bogg, over thirty years in the sector. Previously, colleagues working together at another oil management company, Jamie and Stewart, along with Operations Manager Paul Howley, took the plunge to go it alone in June 2016. In Jamie’s own words, Stewart and Paul were “Stupid enough to say yes” and off they went, leaving the security of an established name in the industry, with a mission to do things differently.

A Decade in the Making

With humble beginnings in a tiny, rented office space and a shared warehouse, these ‘three blokes and a van’ set off to use their experience and contacts within the industry to improve the offering and level of service that already existed.

The OMS team worked hard in the years that followed, touring up and down the UK to visit clients and grow their reputation within the plastics sector. From attending breakdowns and callouts to performing proactive cleans and maintenance, customers saw the financial benefits of performing oil analysis and keeping the ‘lifeblood’ of their machinery in the best possible condition. This lowered energy usage, extended machinery life and brought a range of sustainability and financial benefits to the customers who understood the vision of Jamie and his team.

Ten years on, OMS LubiTek is recognised as a leader in the space, working with almost every established moulding machinery OEM in the UK, with strong working relationships with the likes of ENGEL, Arburg, Billion and BOLE. Now with over 130 active customers and on course to record its first £ 1 million year of turnover, OMS LubriTek has experienced impressive growth over its ten years in business and plans to celebrate its 10-year milestone throughout 2025 and 2026. The team has a range of customer offers, commemorative branding, and designs, as well as celebratory events planned, culminating in 12 months at the Interplas 2026 exhibition at the NEC, Birmingham, in June.

A Comprehensive Oil Management Service

OMS LubriTek offers a broad range of tailored services that revolve around improving oil cleanliness, extending machine life, and helping manufacturers avoid unnecessary downtime and component failure.

Working directly with machinery suppliers and manufacturers, OMS provides high-specification hydraulic oils filtered to meet strict ISO cleanliness levels, ensuring new machines arrive in the best possible condition. They also offer first-fill services and oil flushing, giving OEMs confidence that their equipment is delivered clean and ready to run.

For manufacturers, most commonly injection moulders and blow moulders, OMS LubriTek works closely with maintenance and production teams to assess and optimise the hydraulic systems already in use. Their services include:

- Hydraulic oil analysis using in-house sampling equipment and fluid analysis tools.

- Filtration and water removal to meet or improve OEM cleanliness standards.

- Full oil changes and system flushes, carried out by trained oil management technicians.

- Supply of premium lubricants, such as the GPII UltraLife hydraulic oil range.

- Additive treatments, including their own VRT Ultra Clean additive, are designed to prevent valve sticking and varnish build-up.

Each oil analysis report includes a straightforward traffic-light summary, helping plant teams quickly understand the urgency of any required action, with more detailed diagnostics available as needed.

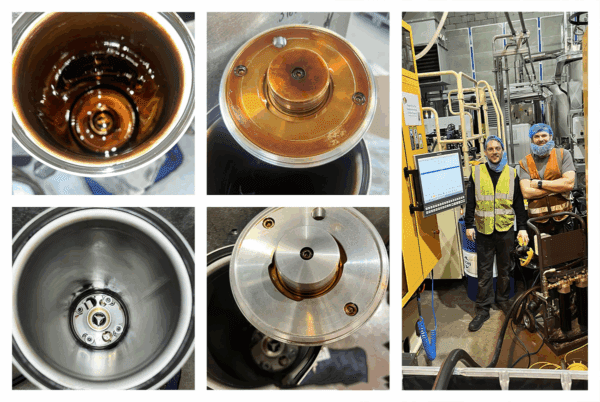

Their custom-built filtration rigs – designed and developed in-house – enable high flow rates, deep filtration, and efficient operation on-site. These rigs are designed for flexibility, allowing OMS engineers to carry out complex fluid management services quickly and cost-effectively at the customer’s location, all over the UK. With so many years on the road, the OMS team is well aware of the small touches that can make a big difference for its moulding customers, with simple things like pre-warming the oil en-route, letting a customer minimise machine downtime, setting them apart from the competition.

Touring the Facilities

During our visit, Jamie walked us through OMS LubriTek’s newly developed premises in Brighouse, West Yorkshire, which include dedicated warehousing, a small laboratory, and an office space designed to support future growth.

The warehouse was well-organised, with rows of lubricant stock including their own-branded GPII UltraLife range – a high-performance Group II base oil formulation – alongside more widely known branded lubricants. Also visible were the custom-built filtration rigs that Jamie and the team have invested heavily in. These rigs, designed with functionality and efficiency in mind, allow for flexible deployment across customer sites, reducing oil change times and increasing overall service responsiveness.

OMS LubriTek places a strong emphasis on education, and its internal systems ensure every client receives tailored recommendations based on their machinery’s requirements and the condition of their oil.

Following the tour, we sat down with Jamie Shaw to discuss OMS LubriTek’s target market, service strengths, and future direction.

Interview with Jamie Shaw, Director at OMS LubriTek

Will Clarke, PlastikCity: Can you tell us about your target market and how OMS LubriTek fits into the plastics sector?

Jamie Shaw, OMS LubriTek: We primarily serve the plastics manufacturing industry, but our work also spans sectors like recycling, automotive, and even aerospace. Within plastics, we support both the machine suppliers, with first-fill services and oil to spec, and the moulders themselves. We’re often called in when there are performance issues, for example, sticking valves or component failure. These issues usually come back to oil quality, and that’s where we come in.

What are your core services and products, and what makes them stand out?

Jamie: Our main services are hydraulic oil analysis, filtration, system flushing, and lubricant supply. What sets us apart is our proactive approach. We’re not just selling oil or turning up for a one-off job. We work closely with production and maintenance teams to prevent issues before they happen and to educate the industry on the benefits of running higher-quality oils and cleaner machinery.

We also supply our own VRT UltraClean additive, which has proven very effective at preventing varnish build-up and sticking valves. And our UltraLife hydraulic oil range is a premium semi-synthetic base oil, rather than mineral oils traditionally used. It’s been proven to have increased thermal stability and resistance to oxidation, which means machines run cleaner and for longer, and use less energy at the same time. We’re really proud of the results and have lots of figures and case studies to prove its success with customers in the UK – we just need to spread the word further, as many manufacturers could be benefiting from these products, which pay for themselves in cost and prevent downtime very quickly.

What would you say sets OMS LubriTek apart from others in the industry?

Jamie: It’s the combination of technical knowledge, equipment, and flexibility. Our team is hugely experienced, with decades of working in the oil and lubricants industries. This means we understand customers’ problems and how to fix them, as well as how we can work in a way that best suits the production teams on the factory floor, minimising the disruption and downtime wherever possible.

We’re also not tied to a single product line or manufacturer. Our goal is always to solve the customer’s problem, whether that’s with a service visit, an additive, a filtration job, or a full oil change. Our technicians are trained, we’ve got nationwide coverage, and we’re always investing in better rigs and equipment. We’ve got our own products but work with all the big suppliers too, so we’re not incentivised down one route or one brand over another. Every client is different, so we can work with them for the best possible solution, whatever the source.

Another thing is education. I know what we do isn’t sexy, customers aren’t always interested in talking and thinking about their hydraulic oil, but we think that is because they’re not aware of the potential benefits and savings. We’ve got figures to back up what we’re saying, back in 2017 we worked with PolyPipe Civils, changing their oil to GP II Ultralife EE, and they saved 8.5% energy usage on the machinery, and they’re still using that same oil 8 years later. The results are proven and plain to see; we just need to get that message out there and continue to educate the market.

What plans do you have for the next 12 months?

Jamie: It’s a big year of celebration for us, as we kicked off the yearlong celebration of our 10th anniversary in June. We’ve got lots planned, promotional branding and special coloured oil barrels for the customers all year, special offers and commemorative touches on some products. Prize draws, special offers, things like that, to engage the customers and to spread the word about our 10 years as much as possible.

Interplas in June 2026 is great timing for us and will be a culmination of the celebration for the 10 years, and we’ve got lots planned for the stand and for the visitors. We’ll then end up with a celebration in July for staff, family and friends.

Other than the 10 years, we’ve got plans for growth, and we’re investing in another branded van, which will increase our availability on the road. We’ll be hiring a new engineer as well, and progressing the staff we have at the moment.

Education is still a huge thing for us, so we’ll be out and about at customer events, open days, exhibitions and the like, spreading the word about what we do and the benefits of looking after your oil.

We’re also looking at other industries, metalworking, aluminium and copper processing – anywhere we can put our expertise to good use.

Will you be exhibiting at any events in the coming year?

Jamie: Interplas in June 2026 is the big one. We’ve got a few promotions and giveaways that will be announced from the show, and we’re treating it as the culmination of our 10-year celebrations.

We’re also considering some smaller regional shows where we can connect more directly with maintenance teams and production engineers. We tend to get the best conversations when we’re on the ground with the people who run the machines every day, and will be travelling up and down the UK all year, visiting customers and potential clients to discuss how we can improve their production.

Finally, do you have a company ethos or guiding principle?

Jamie: Our ethos is simple: treat oil as an asset. If you do that, the machine performs better, lasts longer, and costs less to maintain. Everything we do, from education, filtration, oil supply, or diagnostics, feeds back into that core idea.

We do our best to get that message out there and the industry is waking up to the potential savings that looking after your oil can bring.

After 10 years in business, OMS LubriTek continues to demonstrate that it goes above and beyond for its customers, offering a full oil management service, to supply premium products, as well as improving performance, preventing failure, and educating the industry on the importance of clean, stable lubricants.

Achieving a turnover milestone and starting its 10-year anniversary in the space of a few weeks, it’s a great time to be learning more about the history and the offerings of a company that’s become a household name in the plastics manufacturing industry. With goals to grow further and 12 months of celebrations just kicking off, we’ll be keeping an eye on Jamie and his team in the future!

Thank you to Jamie for the informative tour and for being a PlastikCity member for his entire 10-year history with OMS. Your ongoing support is greatly appreciated and witnessing your growth since the start has been extremely impressive.

Look out for the next edition of ‘PlastikCity on Tour‘ to learn more about our excellent UK-based partners.

There are now well over 260 active partners represented on the PlastikCity site, many of which offer highly specialised products or services to our sector.

During our everyday course of business, we’ll be making a point of visiting as many of these partners as we can and using the time to better understand what they offer the market. We’ll then showcase them through this ongoing series of articles.

Maybe you can benefit from their services!

Read more news from OMS LubriTek here.