Should Aluminium be Considered as a Tooling Material?

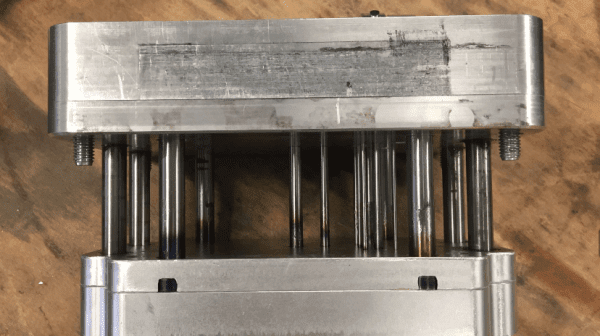

First and foremost, it is essential that we are talking tooling grade aluminium, 7000 series or higher. Softer grades will only survive very short runs and are frequently behind the bad stories people recite.

We believe aluminium tooling offers significant benefits in the suitable applications:

- Being a softer metal, it is faster to machine. This can have price benefits and result in faster delivery times.

- Aluminium has a better thermal conductivity than steel, with the potential to offer reduced cycle times.

- For high gloss finishes, it can be polished about 30% faster.

Commonly asked questions:

Is aluminium a good material to use as a mould tool?

Ask any moulder about aluminium and tooling, and they will all acknowledge that aluminium being softer than the more traditional tool steels requires a little more attention. It is therefore essential to always use a moulder with experience with aluminium tools, so the moulds are looked after.

Alongside this, the mould must be designed and built correctly for practical moulding, prolonging the tool’s life.

How long will an aluminium tool last?

Some tools still run with well over 100,000 shots on them. However, the criteria for aluminium tooling are changing; in the past, it was used only for prototype tooling. You would get 50, 100, maybe 1,000 parts to be used for testing, etc., and then build a steel tool for the production parts.

Today aluminium tools are being used for 50,000, 100,000+ shots for production. Modern surface coatings can also be applied to extend the aluminium tool life.

The key to longevity is the moulded material; add fillers like glass, and the associated tool maintenance will increase, especially in high-wear areas like the gates.

What are the best applications to use an aluminium tool for

Indeed, less complicated parts, point of sale and parts that use a non-abrasive material like polypropylene or a TPE work well with aluminium tools. Higher volumes using more abrasive materials (e.g., glass-filled, ABS) will have a negative impact and shorten the length of the tool life.

What are the surface finish implications of using an aluminium tool?

Most surface finishes can be re-created on an aluminium tool. However, textured finishes will not last as long, and it’s best to allow an increased amount of draft to help with this.

Can you expect the same features of an aluminium tool as you would with a steel tool?

Usually, yes, although some small features may well require inserting in steel to ensure a good life.

How long does it take to make an aluminium tool?

How long is a piece of string?! This depends on the complexity of the parts, however, a simple tool can be produced in a couple of days, whereas more complex devices will require several weeks.

Who owns the tool once it is made?

The tool remains the client’s property once it has been made unless otherwise arranged. Exceptions to this are where MUD frames (fixed bolsters with interchangeable mould inserts), in which case the client would own the inserts only. Plunkett Associates take responsibility for the storage and maintenance of the tool on behalf of the client.

Can parts be over moulded with an aluminium tool?

Yes, we would first mould a rigid plastic substrate, and then a soft rubber or TPE would be moulded onto or around the substrate. This is often used for products that need a soft grip area to a rigid part.

Do you know a toolmaker who is experienced in making aluminium tools

Yes, Plunkett Associates have trusted suppliers in the UK, including our sister company, Adept Precision. If tooling is originating from the Far East, then we would source steel tools as controlling the grade of aluminium used can prove challenging!

Read more from Plunkett Associates here.

Plunkett Associates

+44 (0)1452 386608

Website

Email