HotSeat: Steve Thomson, New Managing Director at ARBURG Limited

|

Getting your Trinity Audio player ready...

|

ARBURG is a huge name in injection moulding, known for its precision, innovation, and sustainable manufacturing. With a large UK presence, the company continues to support moulders through automation, recycled material technologies, and tailored customer service.

In this PlastikMedia HotSeat, Steve Thomson, who will assume the role of Managing Director following Colin Tirel’s retirement at the end of November 2025, reflects on the changes in the UK plastics industry and ARBURG’s role in helping manufacturers adapt. From embracing post-consumer recycled materials to deploying AI-assisted automation, ARBURG is focused on delivering smart, future-ready solutions that meet the demands of a changing market.

What trends do you think will shape the future of UK plastics? How will ARBURG respond?

The perception of plastics in the UK is often marred by negative media portrayals. However, having been in the industry since my apprenticeship in 1991, I believe that plastics still represent the most effective solution for many applications. While concerns about plastic waste are valid, initiatives like wooden cutlery and the ban on plastic straws sometimes miss the mark. For instance, the shift to paper pulp alternatives often fails to meet performance standards—anyone who has tried drinking a takeaway coffee recently can attest to that!

The initial rush to replace traditional materials with plastics, such as the move from aluminium and wood to PVC windows, has moderated. Yet, there remains a wealth of innovatively designed components crafted from a diverse range of advanced materials.

In the UK, the production of plastic components is increasingly being approached with a focus on automation—something that has traditionally been underutilised. In response, ARBURG has been prioritising the development of post-consumer recycled (PCR) technologies and automation solutions, both with and without AI integration. We currently have several sophisticated automation cells operating across the UK, showcasing our commitment to innovation in this evolving landscape, and several AI-assist programs that can support moulders using PCR with inconsistent properties.

How has ARBURG developed during your tenure?

Throughout my career, I have witnessed ARBURG’s remarkable evolution. The brand is well-respected and recognised within the industry, yet it is often still perceived as the “small machine guys,” a reputation stemming from the iconic 35-ton two-tie bar machines that laid the foundation for the company in the 1980s. These machines continue to operate in mould shops across the UK today.

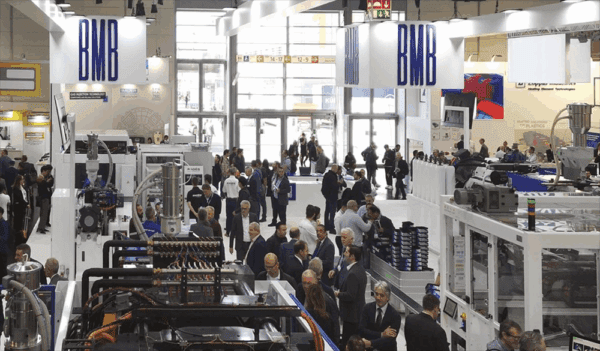

At trade shows, ARBURG’s presence is unmistakable, reflecting the importance of brand identity to this family-owned company. The granddaughter of the founder, who serves as the Global Marketing and Business Development Director, is based at our headquarters in Lossburg, Germany, ensuring that the company’s legacy and vision remain strong.

As a newcomer to this 102-year-old business—having joined in September 2024—my perspective is somewhat limited. However, I have noted a deep-seated modesty within the Swabian culture, where the company originated. This humility is evident when engaging with professionals in industries not traditionally associated with ARBURG, such as packaging. Our capabilities have expanded significantly; we now manufacture machines with locking forces up to 650 tons, regularly producing closures using single-face, stack, and even CUBE mould technology.

What do you credit as the key to your success?

I feel my success has been down to a number of factors which has influenced me over the years. Primarily, I think my natural curiosity about plastics, injection moulding and production gave me a strong foundation to build upon. Next, it would be my exposure to several industries, working in different roles & companies where I also worked within some really talented teams that coached me to think strategically, and not be afraid to be bold & adapt. Finally, I’d like to think that I’ve always fostered a good team spirit and built good relationships.

Having the support of a good manager who can coach you to become better is important to me and something I am passionate about, to pass that knowledge on to the next generation.

What has been the greatest challenge in your career?

The greatest challenges often arise unexpectedly. External factors and shifts in customer expectations can significantly alter the course of an opportunity, whether due to design changes, sustainability concerns, or aesthetic preferences.

However, my most significant challenge has been personal: the paralysis of my right arm following an accident in September 2023. This experience has forced me to adapt and learn to navigate daily tasks using only my left arm. Despite this setback, I am determined to persevere and am not ready to give up the fight just yet.

What advice do you wish you’d had on entering the industry, and does that differ from the advice you would give to an apprentice joining now?

It’s interesting you ask this, as it’s a topic I’ve discussed several times recently! I was never particularly academic, and as soon as I could leave school, I was eager to start an apprenticeship in September 1991. I believed that completing those four years would grant me the keys to the world. Little did I know, life had much more in store for me!

I often reflect on myself and fellow apprentices sitting around the lunch table, engrossed in discussions about cars, girls, and music. Fast forward 33 years we still get together but now find ourselves in Directorship roles in our respective fields (Technical, Sales, Aftersales, and Managing Directorship), wondering how much has changed!

If I could sit my younger self down, I would emphasise that every experience adds a valuable string to your bow and contributes to your journey through life. My advice to apprentices today would be similar: embrace every opportunity, remain driven, and continue to grow. The potential for success is certainly out there, waiting for those who seek it!

What hidden talents do you have?

From a young age, I’ve had a passion for cars. As an apprentice, I got my first car and started tinkering with it, thanks to the support of some experienced friends. My fascination with Renaults began after a ride in a 5 GT Turbo, provided by someone else in the plastics industry during my tech college days. Since then, I’ve owned ten Renaults, and I currently have six in my collection!

My interest goes beyond merely owning and driving these cars; I’ve developed a passion for restoring them. Over the years, I’ve rebuilt four Renaults, earning awards and recognition for my work. My cars have even been featured in several magazines and on UK television.

I firmly believe that cars should be enjoyed, and just this past June, my wife and I took my 5 GT Turbo to the annual meet in Rotterdam for the weekend, fully confident in its performance!

Read more news from ARBURG here.

ARBURG

01926 457000

Email

Website