Sumitomo (SHI) Demag Highlights the Value of Proactive Injection Moulding Maintenance

|

Getting your Trinity Audio player ready...

|

Investing time and resources in keeping your injection moulding machinery in the best condition can eventually save you time and money. It can even increase your production capacity and profitability. Nick Stockton, Technical Manager at Sumitomo (SHI) Demag UK & Ireland explores how and why unmaintained machinery can be irksome and a drain on all resources.

Effective maintenance practices are the cornerstone of every operationally efficient and profitable injection moulding facility. It involves a wide range of preventative measures targeted at extending equipment lifespan, protecting valuable tooling assets and workforce safety, and ensuring machine breakdowns don’t interrupt production schedules. It can also help processors to monitor energy consumption and pinpoint where improvements could be made. Which in turn reduces demand on available energy sources.

As in life, the feeling when hours are lost can be as appliable to machine downtime. It can leave people feeling powerless and frustrated. Skipping regular checkups in anything can lead to much costlier outcomes and more exasperating interventions. Adopting a ‘run to failure’ approach can be equally risky. Especially when customer schedules and stock holdings are so reliant on quick, seamless component deliveries.

When unplanned downtime occurs, no value is being produced. Yet, operational overhead costs continue to grow, directly impacting net profits.

“There are numerous benefits to having a well maintained machine fleet. As well as increasing efficiency and extending the lifespan of equipment, machines that are well maintained are also easier to service and diagnose issues when they arise. Additionally, because the machines are running at their optimal level, this also helps to reduce energy consumption,” emphasises Nick Stockton.

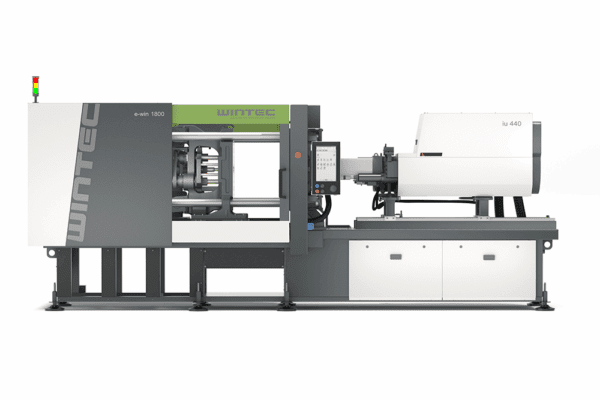

Caring for your assets

Time-based maintenance schedules have long been available to Sumitomo (SHI) Demag customers. As well as being the first UK injection moulding company to set up annual machine checks nearly 30 years ago, between in early 2000 the company also established a rewards program. This provided customers with additional tangible business benefits, including discounted spare parts, the assurance of engineer availability, guaranteed response times, a free ErgoCheck for the first year on every new machine, as well as a cap on the total cost of a breakdown. These kinds of rewards were all a first in the polymer processing industry.

Still going strong, this annual ErgoCheck test remains as popular as ever. The UK and Ireland arm of the company continues to carry out more than 400 each year to help ensure that each machine is still operating in accordance with the original manufacturer’s protocols and design performance.

After each ErgoCheck check-up, the Sumitomo (SHI) Demag service team issues each customer with a certificate as well as a copy of the condition and measurement monitoring reports. If a machine fails to meet the original factory settings, customers receive a detailed report and quotation, breaking down the steps needed to bring a machine back up to specification.

This original service has also evolved into the creation of activeCare, offering enhanced value by checking performance as well as changing maintenance components.

For a fixed price, each activeCare report covers a complete service, including lubrication through to changing filters, exchanging batteries and checking everything from the toggle system to belt tension, screw concentricity and dosing speed. All of the kit and labour is included in the price. “Customers especially value being able to budget for these machine services each year knowing that there will be no financial service surprises,” adds Nick. Discounts are also available if two machines are inspected and serviced on the same day, with additional saving if more machines are serviced in the same calendar week.

No value in vulnerability

With support being delivered entirely by injection moulding machine engineers, the technical expertise coupled with familiarity of sector-specific routine tasks ensures that no aspect is overlooked.

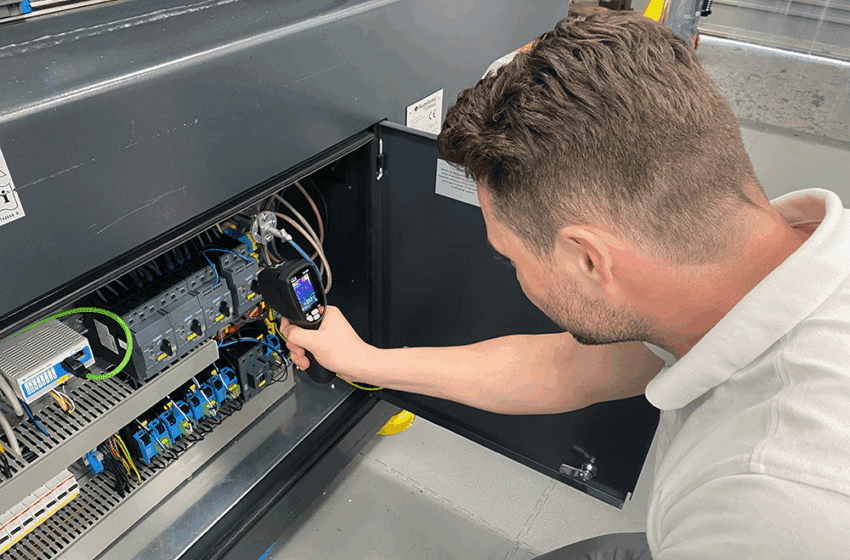

“There are so many things we inspect for which can impede machine performance. From looking for cabinet hot points to checking the battery backups. All of which can help to break the cycle of reacting to emergency maintenance tasks,” affirms Nick.

It might sound obvious, but the single biggest thing users can do to ensure machine reliability and longevity is to carry out the service work tasks specified by the machine and the user guides.

These tasks can be simple to perform. But without a dedicated maintenance person can frequently be overlooked. Planned maintenance invariably has a lesser impact on production line efficiency than unscheduled downtime caused by a failing machine part.

One of the most common issues occurs as a result of processors switching off the back up batteries for the weekend, reports Nick. The energy savings for this can be negligible. Yet, it can result in the entire software program needing to be reinstalled.

Year-round oversight

Rather than following set intervals for certain tasks, machine data can be used to adjust service plans according to usage. The result is a far more customised and responsive plan than a traditional ‘fixed’ approach.

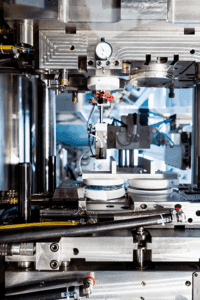

To make this process easier, electric moulding machines offer even more inbuilt data gathering capabilities. Parameters such as machine acceleration and deceleration and forces and motor duty cycles are all checked via sensors. This provides a more detailed and complete optimisation picture.

The next step is supporting processors to move to a more predictive approach to servicing and maintenance. The optimum time to change a part is just before it fails. With the latest injection moulding machines this is entirely possible, as there’s now the pre-emptive technology that can alert users to what maintenance needs to be carried out and what parts need to be replaced in advance. For example, without predictive maintenance a worn clamp unit or a faulty valve may go undetected until it causes serious quality problems. With predictive maintenance, this scenario shouldn’t arise because the issue has already been anticipated and the specific part replaced.

Using thermographic equipment, condition monitoring is another service included in the annual activeCare check. Rather than a ‘best guess’ diagnosis, activeCare engineers provide quantifiable measurements to determine when equipment or parts are likely to fail in service.

“Being able to monitor, test and check all critical areas of machinery assets, using equipment that is calibrated to ISO 9001 and VDA 6.4 certification standards, helps instil confidence and provide early ‘red flag’ warning signs of potential problems,” adds Nick

Read all of Sumitomo (SHI) Demag’s latest news here.

Sumitomo (SHI) Demag

01296739500

Email

Website