Gum for Good: Sustainable Testing Solutions by Great Central Plastics & HWU

|

Getting your Trinity Audio player ready...

|

Heriot-Watt University has teamed up with plastics manufacturer Great Central Plastics to develop innovative medical testing equipment from Gum-tec, a material created from chewing gum scraped from UK streets. The project has attracted national media attention as the medical sector strives to become more sustainable.

Glasgow’s Heriot-Watt University and Great Central Plastics, a Northamptonshire-based moulding company, have embarked on an innovative project to repurpose discarded chewing gum and old fridge components into sustainable medical devices.

The collaboration focuses on creating lateral flow tests (LFTs), with the goal of significantly reducing the carbon footprint associated with these single-use medical testing products, with the use of alternative, sustainable raw materials. LFTs test for a wide range of illnesses, with an estimated four billion of these small plastic devices manufactured every year. This initiative aims to address the approximate 16,000 tonnes of plastic waste generated by LFTs worldwide.

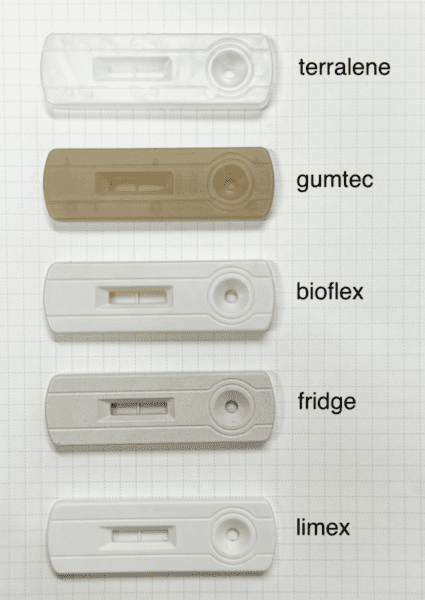

By integrating High Impact Polystyrenes (HIPs) derived from “post-consumer” materials, such as Gum-tec from used chewing gum and HIPs from end-of-life fridge parts, into the manufacturing process, the project presents a sustainable alternative that could reduce carbon emissions of the devices by 30-80%.

Maiwenn Kersaudy-Kerhoas, a professor in microfluidic engineering at Heriot-Watt University, worked closely with moulding company Great Central Plastics to develop lateral flow tests in alternative materials.

Professor Kersaudy-Kerhoas said “We’ve now had approval to test these prototypes, making sure they function as well as the existing ones, particularly regarding the flow of liquid on the testing strip.

“As well as demonstrating feasibility in their practical application, these new devices help to support a wide-ranging discussion around healthcare sustainability in general and how we might develop a circular economy through potential changes in procurement and legislation.”

Great Central Plastics’ expertise in sustainable materials was pivotal to the project’s success, leveraging its specialised knowledge in sourcing and manufacturing from a range of recycled and sustainable materials.

Kiron Phillips, Head of Sales and Marketing at Great Central Plastics, adds: “We take pride in our sustainable manufacturing processes, and we adopt this ethos across all levels of our business. This collaboration highlights our commitment to cutting-edge research and development.

“By championing sustainable alternatives such as Gum-tec and Limex, we not only mitigate environmental impact but also pioneer a shift in the industry, setting a benchmark for responsible production practices.”

The collaboration between Great Central Plastics and Heriot-Watt University combined pioneering academic research with practical materials and moulding know-how, leading to very successful early results.

The project is particularly exciting as medical device manufacturing has traditionally been an area of plastics manufacturing hesitant to adopt recycled or post-consumer raw materials, due to the strict legal and regulatory requirements governing the safe use of medical products. This collaboration hopes to make progress towards these goals, reducing plastic waste in the healthcare environment.

Professor Kersaudy-Kerhoas adds “After our rigorous scientific, economical and regulatory investigations, recycled plastics could be used with existing equipment and be a quick win for some products like LFTs.”

The project has also attracted national media attention, with coverage in the Independent and ITV, amongst others. Kiron Phillips and Professor Kersaudy-Kerhoas also appeared on Scottish television discussing the project on Friday 15th March.

You can watch the full STV news report below. (Video courtesy of STV News.)

Read more news from Great Central Plastics here.

Great Central Plastics

+44 (0) 1327 264277

Website

Email