Tekniplaz Expands High-Precision Machining Capabilities with Investment in Röders RXP500

|

Getting your Trinity Audio player ready...

|

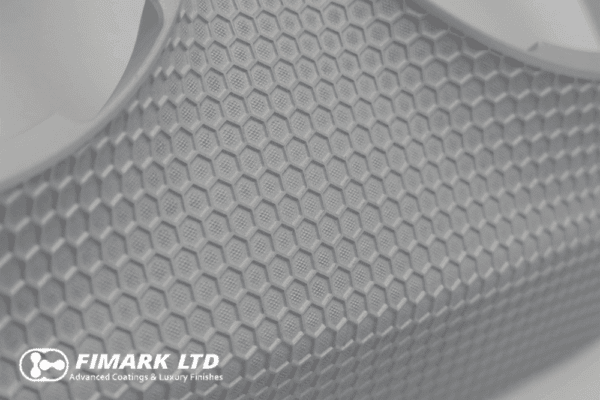

UK mould toolmaker Tekniplaz Ltd has made a significant investment in its machining capabilities with the recent installation of a Röders Tec RXP500 high-speed vertical machining centre, supplied by Hurco Europe. This latest addition to the company’s state-of-the-art facility reflects Tekniplaz’s continued focus on precision engineering and commitment to meeting the increasingly stringent quality demands of its customers in the medical, electronics, and other high-performance sectors.

The RXP500, known for its exceptional dynamic accuracy and stability, is paired with Open Mind hyperMill CAM software, including the hyperMill Electrode module, and is complemented by a dedicated Meusburger H1000 pallet clamping system. Together, the package enhances both the accuracy and repeatability of toolmaking operations at Tekniplaz.

At the heart of the RXP500 is Röders’ advanced linear direct drive system, providing backlash-free motion and rapid feed rates up to 42,000 mm/min. This enables faster cycle times without compromising on quality, even during complex 3D contouring. Combined with thermal compensation, high-resolution optical encoders, and Röders’ patented spindle elongation compensation, the machine ensures long-term stability and sub-micron precision in even the most demanding applications.

Further distinguishing this installation is its integrated Blum laser tool measuring system and contact-point part inspection, allowing comprehensive in-machine validation. These systems significantly reduce the need for external measurement and further shorten lead times – something increasingly valuable in the fast-paced development cycles of modern manufacturing.

The RXP500 also complements Tekniplaz’s existing EDM capabilities, which include linear motor Wire EDM and CNC Sink EDM technology. With all finishing operations now operating at consistent micron-level tolerances, the company can offer a truly end-to-end precision tooling service, from roughing through to final finishing – entirely in-house.

“This investment further strengthens our ability to meet and exceed customer expectations for high-precision, high-quality tooling,” said Anthony Marsh, MD of Tekniplaz. “The speed, accuracy and reliability of the RXP500 make it ideal for complex workpieces where even the smallest deviation is unacceptable.”

Manufactured in Germany, Röders machines are well respected across the globe for their innovation in High-Speed Cutting (HSC) technology. With more than 200 years of engineering heritage and over 3,000 machines installed worldwide, Röders remains at the forefront of ultra-precise, high-efficiency machining solutions. The RXP500’s ability to perform roughing and finishing in one set-up, along with features such as TOOLFIT® tool probing and precise temperature-controlled components, reinforces its reputation as a true production-class system for mould and die makers.

This latest investment follows Tekniplaz’s broader strategy of building a resilient, locally based supply chain, supported by advanced in-house capability. Having reshored its manufacturing operations in 2016, the company continues to provide a complete turnkey service, from concept development and prototyping to toolmaking and production.

To learn more about Tekniplaz’s toolmaking capabilities, visit their website or contact their team on 01623 880 400.

Read more news from Tekniplaz here.

Tekniplaz

01623 880 400

Website

Email