More Productivity Through Less Scrap: Greater Process Reliability with Temperature Control Solutions from ENGEL

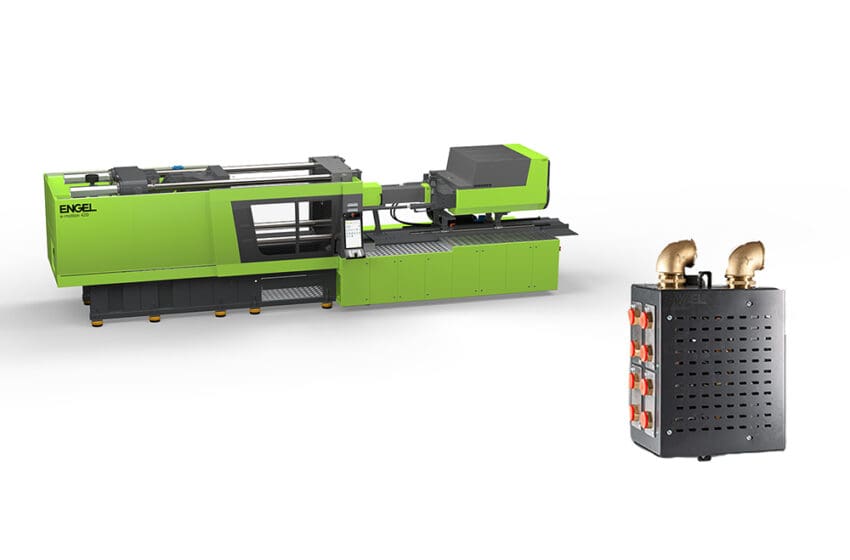

With innovative solutions for mould temperature control, ENGEL is setting new standards in efficiency, quality and sustainability at K 2025. ENGEL is presenting a complete temperature control portfolio covering various temperature and flow rate ranges.

The focus is on reducing cooling water consumption by 50%, achieving high flow rates, and introducing new, more robust temperature control water distribution systems with ultrasonic sensors. This enables ENGEL to ensure reliable mould temperature control from very low temperatures up to 160 °C – a tangible step forward towards stable and resource-efficient injection moulding processes.

Mould temperature control is one of the most sensitive influencing factors in injection moulding production. Errors in this area are among the most frequent causes of rejected parts. Changes in the water supply or ambient conditions can lead to scrap or unplanned downtimes. At the same time, mould temperature control often accounts for more than 40% of the total energy consumption in an injection moulding operation. ENGEL addresses these challenges with over 15 years of development experience and a consistent strategy for process-integrated temperature control monitoring – located close to the machine, fully integrated and designed for practical use.

e-flomo and eco-flomo temperature control water distribution systems with ultrasonic sensors for temperatures up to 160 °C

ENGEL has further developed the success story of flomo and e-flomo and is presenting the new generation at K 2025. New materials – for example, in the fields of e-mobility and medical technology – require increasingly higher mould temperatures. For this reason, the new generation of temperature-controlled water distribution systems is available for use at temperatures of up to 160 °C. Particularly at high temperatures, cooling water quality is often critical, and accurate flow measurement becomes problematic. In view of this, the enhanced versions of ENGEL’s e-flomo and eco-flomo are available with ultrasonic sensors. Thanks to this contactless flow measurement, the devices are especially robust, reliable and at the same time precise – even at very low flow rates.

ENGEL is now extending its well-established process stability and energy efficiency to applications in this very high temperature range as well – regardless of the specific requirements – by offering this portfolio expansion as a one-stop shop.

e-flomo one: Intelligent cooling water control for high flow rates

Another highlight in the field of temperature control is the new e-flomo one. It has been specially developed for applications with high cooling water demand and high system availability, such as in the packaging sector. The moulds used in these applications are often supplied via a central cooling circuit. These supplies are frequently subject to fluctuations in pressure and flow, depending on the level of production utilisation. The e-flomo one compensates for such fluctuations in supply within seconds – making a decisive contribution to reducing scrap and increasing process consistency. The e-flomo one controls both the flow rate and the temperature differential directly at the main cooling water inlet of the injection moulding machine. As a result, e-flomo one can reduce cooling water consumption by up to 50 %, which corresponds to potential savings of up to €10,000 per year.

The e-flomo one has been developed for moulds with high cooling water demand and controls flow rates of up to 600 l/min.

e-flomo ONE & eco-flomo XL: Process reliability and efficiency for high flow rates

The new ENGEL eco-flomo XL has already proven itself in the packaging sector as a high-performance solution for moulds and production systems with cooling water flow rates of up to 100 l/min per cooling circuit and is considered a success. To further increase process reliability and energy efficiency, ENGEL also offers the combination of eco-flomo XL with the new e-flomo one. This enables precise single-circuit monitoring, ensuring maximum process consistency. At the same time, the e-flomo one maintains a constant flow rate, which optimises cooling performance and contributes to the stabilisation of the entire injection moulding process.

Customer benefits in focus – compact summary:

With ENGEL’s new temperature control solutions, injection moulders benefit in multiple ways: the systems actively help prevent scrap, immediately highlight weak points in the temperature control process, and permanently improve process stability. At the same time, they significantly reduce water and energy consumption – even under fluctuating ambient conditions. Full integration into the machine control system reduces operator workload and the potential for errors. ENGEL thus provides an end-to-end solution that sustainably enhances both the quality and cost-efficiency of production.

Visit us at K 2025 in Düsseldorf, Hall 15, Stand B42 & C58

Read more news about ENGEL here.

ENGEL

+44 (0)1926 335000

Email

Website