Taylor Engineering & Plastics Invests in the UK’s Largest Ever Wittmann Battenfeld Injection Moulding Machine

|

Getting your Trinity Audio player ready...

|

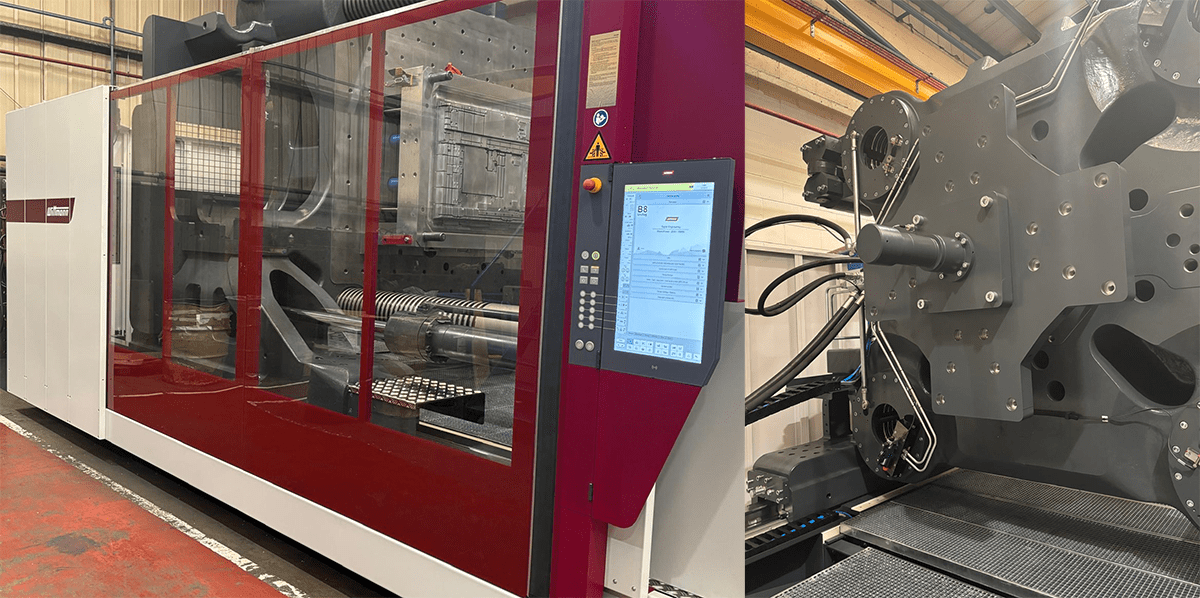

Taylor Engineering & Plastics (TEP) has strengthened its manufacturing capacity with the installation of a new 2200T Wittmann Battenfeld MacroPower injection moulding machine at its Rochdale manufacturing facility.

Valued at over £1 million, the MacroPower 2200/33000 is the largest clamping force Wittmann Battenfeld machine installed in the UK as of September 2025. The new machine was delivered and installed on 3 September, with production scheduled to commence in the coming weeks.

Expanding capacity for large-scale moulding

With a clamping force of 2,200 tonnes, a 33,000-injection unit fitted with a 180mm screw, shot weights in excess of 20kg, and a platen size of 2.487m x 2.287m, the MacroPower is a behemoth of a moulding machine, and expands TEP’s ability to produce large, technical components for demanding applications.

The machine will be used for both compact injection moulding and structural foam moulding, offering new flexibility to support a wide range of market sectors and customers.

The turnkey system was supplied by Wittmann Battenfeld UK and includes a complete package of automation, materials handling, drying, and blending equipment, all with industry 4.0 connectivity and circular economy technology, ensuring efficiency and repeatability across high-volume production.

A long-standing partnership

TEP works with a range of leading injection moulding machine manufacturers and operates a variety of platforms across its production facilities.

However, the company’s relationship with Wittmann Battenfeld UK is longstanding, dating back to 1984 when Battenfeld supplied and installed TEP’s first thermoset injection moulding machine. Today, the 40-year strong relationship continues with the installation of the largest clamping force Wittmann Battenfeld machine in the UK.

Speaking about the new installation, Scott Taylor, Managing Director at TEP, commented: “This latest investment demonstrates our continued commitment to expanding capacity and capabilities at TEP. The new MacroPower 2200 provides the scale and performance needed to meet growing demand for large, moulded components across multiple industries.

“This machine marks a significant addition to our Rochdale facility and will support further growth in the years ahead.”

Dan Williams, Joint Managing Director at Wittmann Battenfeld UK, added: “TEP and Wittmann Battenfeld UK have enjoyed a strong relationship spanning more than four decades, and it is great to see that partnership continue with the installation of this flagship MacroPower machine. This 2200T model is the largest clamping force machine we have supplied in the UK to date, and it underlines the confidence and ambition within UK manufacturing. We look forward to seeing the machine in full production and continuing our long-standing collaboration with the team at TEP.”

Orrin Smith, Wittmann Battenfeld UK’s Area Sales Manager, involved in the project, further comments on the alignment between the two companies: “The Taylors have a deep understanding of large-scale engineering, as does the Wittmann family, so it was a real pleasure to host them at our production facility in Austria for the factory acceptance test.

“I have thoroughly enjoyed every stage of this project—from receiving the order, working together on technical challenges and then overseeing the installation at the TEP site. I am confident this machine will serve the customer well for a long time and help to put us back on the map for MP2000+ size machines.”

Further investment planned

The installation of the MacroPower machine doesn’t mark the end of the current expansion project for Taylor Engineering & Plastics, with further plans to increase investment in machinery, including the incorporation of an entirely new manufacturing process into the Rochdale facility, due for commissioning by the end of Q2 2026.

A positive outlook

In a turbulent market, it is reassuring to see the continued confidence and investment from a UK plastic industry stalwart, with full support, automation and ancillaries provided by top-quality OEMs such as Wittmann Battenfeld UK.

With five sites and a variety of moulding and post-moulding processes under its roof, Taylor Engineering & Plastics is a one-stop shop for the manufacture of plastic components for a variety of industries.

With expertise in tooling provision, thermoplastic moulding (compact injection and structural foam), plus thermoset moulding (DCPD), as well as offering a wide range of painting and assembly processes, the TEP team is perfectly placed to meet a wide variety of project needs.

Read more news from Taylor Engineering & Plastics here.

Taylor Engineering & Plastics

01706 714700

Website

Email