Sterling Ancillary Services Providing Maintenance Support for Plastics Processors

|

Getting your Trinity Audio player ready...

|

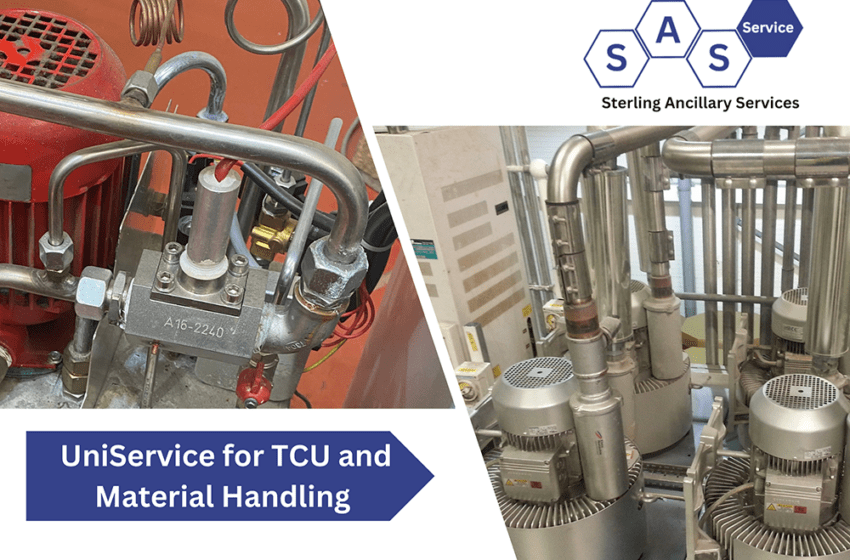

Ensuring operational efficiency is crucial for manufacturers looking to stay competitive. With over 30 years of experience, Sterling Ancillary Services (SAS) provides expert maintenance for temperature control units (TCUs) and material handling systems, supporting UK moulders and the plastics processing industry. SAS helps businesses optimise performance, reduce downtime, and maintain the reliability of essential production equipment.

Temperature Control Units (TCUs)

TCUs play a critical role in maintaining consistent processing conditions but are often overlooked. SAS has the expertise and resources to service and maintain TCUs across all brands and models. Its comprehensive maintenance programme includes flow rate checks, heating element assessments, electrical circuit inspections, pump servicing, and system optimisation. By ensuring TCUs operate efficiently, SAS helps manufacturers maintain consistent moulding quality and production efficiency.

Material Handling Systems

A reliable material handling system is the foundation of efficient polymer processing, ensuring the consistent and accurate delivery of materials. SAS has extensive experience installing, servicing, and maintaining handling systems for both the plastics and food industries, covering pellets, flakes, and powders.

As part of its service visits, SAS carries out:

- Pipework inspections and renewals

- Loader maintenance

- Control panel servicing and upgrades

- Pump and filter servicing

By maintaining and optimising these systems, SAS helps manufacturers avoid material flow disruptions, keeping production running smoothly.

Optimisation

Optimisation is key to maximising performance and reducing waste. SAS analyses material flow, pump runtimes, and filter efficiency, making precise adjustments to improve:

- Energy efficiency

- Housekeeping standards

- Machine uptime

Through expert optimisation, SAS helps businesses reduce operational costs and minimise equipment wear.

Benefits

Booking an SAS Uniservice visit is a competitive, cost-effective way to keep all your ancillary equipment running, and with significant improvements to be gained through increased production, lower energy usage and improved quality of product, a return on your investment from the service, is guaranteed.

Read more news from Sterling Ancillary Services here.

Sterling Ancillary Services

+44 (0) 7786991444

Email

Website