BMB to Showcase High-Performance Hybrid and All-Electric Solutions at K 2025

|

Getting your Trinity Audio player ready...

|

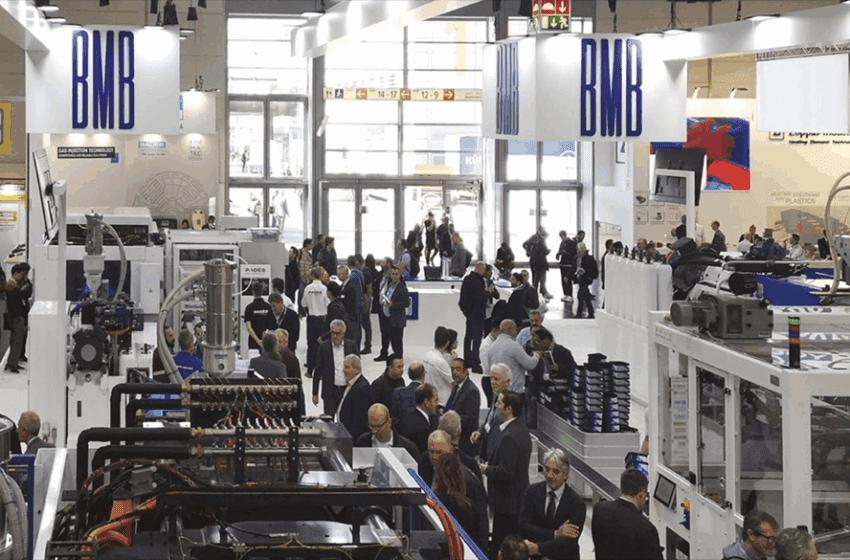

BMB will exhibit a selection of advanced injection moulding technologies at K 2025, demonstrating the company’s focus on productivity, energy efficiency, and long-term reliability. Visitors can find BMB in Hall 13, Stand A33 from 8–15 October in Düsseldorf, Germany.

With more than half a century of continuous ownership and machine development, BMB remains one of the few injection moulding machine manufacturers offering stable, long-term support. This heritage underpins the company’s ability to supply original spare parts decades after production, reflecting a commitment to quality and product evolution.

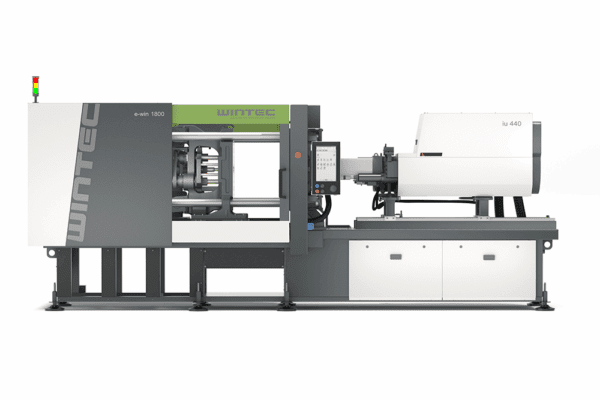

BMB’s presence at K 2025 will highlight the company’s expertise across thin-wall packaging, caps and closures, and high-speed food packaging applications. Four working cells will be in full production on the stand, each representing a different configuration of hybrid or all-electric technology.

eKW55HP/5500 WP HYBRID + 150 FULL ELECTRIC

Application: 6.6-litre paint bucket with virgin PP handle

Cycle time: ~6 seconds

This cell replicates a real production setup and will be delivered directly to a Dutch customer after the show. The machine combines a hybrid injection unit with a secondary fully electric injector to produce a bucket in PCR material and a virgin PP handle. The HP series delivers high injection speeds and precise platen parallelism, essential for thin-wall moulding with reduced part weight and tight tolerances.

Energy consumption and maintenance costs are reduced through direct-drive motors with recirculating roller screws for both plasticising and clamping, supported by iQ servo-pump technology for accumulator charging. The system can also alternate between polypropylene and metal handles during production.

eKW45HP/3450 WP HYBRID

Application: Mineral water caps (96 cavities)

Cycle time: ~2.6 seconds

This machine is specifically designed for caps and closures, offering a compact footprint, robust construction, and very high-speed performance. A lightweight injection piston enables fast, accurate movements, while electric drives for plasticising and mould movements are combined with a hydraulic injection system featuring dual servo valves and accumulators for energy-efficient operation.

The redesigned toggle system ensures rapid, parallel clamping, supporting the short cycle time. The cell includes an in-line vision system and automated cardboard packaging.

eKW16Pi/700 FULL ELECTRIC

Application: 100 ml food container

Cycle time: <1.9 seconds

This fully electric system delivers high output and repeatability, achieving an injection speed of 350 mm/s and 2000 bar pressure for thin-wall applications down to 0.36 mm. All machine movements are electric, driven through recirculating roller screws for precision and durability.

A three-camera vision system and a six-axis collaborative robot handle packaging efficiently, while servo-driven axes with overlapping movements maintain consistent 3.4 g part weights.

eKW28Pi/1300 HYBRID

Location: Enelkon stand, Hall 12 / A43

Application: 400 ml food container

Cycle time: ~3.9 seconds

This hybrid machine showcases BMB’s strength in thin-wall applications, supported by IML, vision systems, and collaborative robotics. Hybrid solutions form a core part of BMB’s portfolio, valued for their versatility, low energy use, and long service life. The iQ-Pump system delivers additional energy savings, and injection-compression moulding capabilities are supported through electric drives for clamping, opening, and plasticising. This cell highlights the ongoing collaboration between BMB, Enelkon, and Eramould.

Machine control technology

BMB will also present its latest machine controller, developed to support advanced digitalisation and Industry 4.0 integration. A mechanical keyboard provides direct access to the main machine functions, while a virtual touch keyboard allows flexible programming. Operator recognition enables different access levels depending on role.

Integrated manuals, online help, peripheral connectivity, and data collection are embedded within the CNC control to support process optimisation and productivity.

Michael Craig, the Area Sales Manager For UK & Ireland, will be available on the stand throughout the show. To book a meeting, please use the contact details below:

Mobile : 07551 312685

Email : Michael.Craig@bmb-spa.com

To read more about BMB Machinery, click here.

BMB Plastics Machinery Limited

+44 (0) 7551 312685

Website

Email