Cytec Systems UK are Pleased to Offer Tunnel Gates from i-mold

|

Getting your Trinity Audio player ready...

|

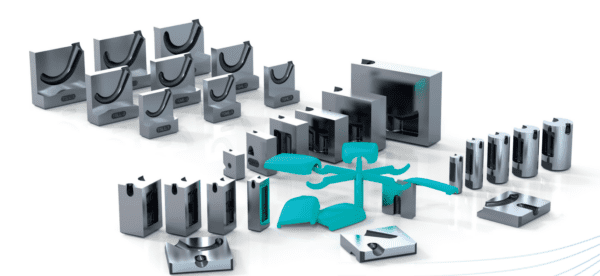

CyTec Systems UK Ltd, the leading supplier of hydraulic cylinders & servo automation, are delighted to introduce tunnel gates from i-mold. The tunnel gate inserts from i-mold are renowned in the industry for their innovative design and their ability to significantly reduce costs for both mouldmakers and moulders.

Here’s why they are recognised worldwide:

- Innovative Design: Tunnel gate inserts from i-mold feature a unique design that allows for efficient gating of plastic parts directly at the parting line of the mould. This design eliminates the need for conventional gating systems, such as runners and gates, which often result in material wastage and increased cycle times.

- Cost Reduction: By eliminating the need for conventional gating systems, tunnel gate inserts help reduce material wastage, cycle times, and post-processing requirements. This reduction in production costs can be significant, leading to substantial savings for both mould makers and moulders over the lifecycle of a mould.

- Improved Part Quality: Tunnel gating offers more precise control over the flow of molten plastic into the mould cavity, resulting in parts with improved surface finish, reduced weld lines, and minimal gate vestige. This can lead to higher quality finished products and fewer defects, further reducing costs associated with scrap and rework.

- Global Recognition: i-mold’s tunnel gate inserts have gained widespread recognition and adoption across the globe, attesting to their effectiveness and reliability. They are trusted by mould makers and moulders in various industries for their ability to optimise production processes and enhance the competitiveness of manufactured parts.

Why gate inserts?

• Time and cost reduction thanks to fast and easy application;

• Made of highly wear-resistant hot work tool steel M2 (1.3343);

• High degree of reliability in production process;

• Invisible gate marks through underside gating;

• Single-part design for compact dimensions;

• Available in many different versions and sizes;

• Integrated cutting edge for exact sprue separation;

• Suitable for all plastics thanks to optimized feed channel geometry– up to 60% filler content (e.g.

glass fibre) is possible;

• Use of MIM process ensures smooth feed channels and exact gate sizes; and

• Easy CAD download.

Overall, the tunnel gate inserts from i-mold represent a cutting-edge solution for optimising injection moulding processes, offering tangible benefits in terms of cost reduction, improved part quality, and enhanced efficiency.

Get the PDF catalogue here.

Read more news on CyTec Systems UK here.

CyTec Systems UK

0161 6787090

Website

Email