More efficient spraying with KraussMaffei

A wide bristle brush creates more surface area than a round brush, better suited for detail. What everyone knows from painting also applies to spraying PUR using the SCS process. However, applications usually require both – and KraussMaffei offers the necessary flexibility with its innovative nozzle change technology. From flat to round jet nozzle in seconds – and vice versa.

SCS (Structural Component Spraying) is amazing: a paper honeycomb layer pressed with a glass fibre mat and visible fleece can withstand considerable weight as a loading floor in the trunk or on car roofs. The prerequisite is polyurethane (PUR), with which the glass fibre mat was previously sprayed. There are different areas here: the large surface itself and the edge zones, which need to be reinforced so that they are not damaged by the sharp tool edges that punch simultaneously. Local reinforcement is also often necessary for metal or plastic inserts. So, you need a spray nozzle that covers large areas and precisely places the PUR.

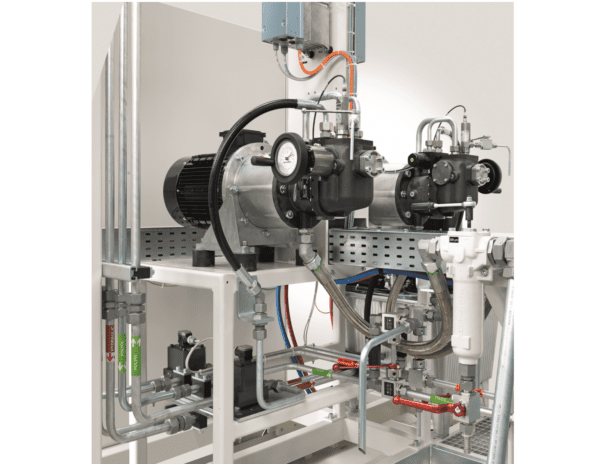

KraussMaffei was the first to succeed in establishing a process on the market in which both (each with its mixing head) are operated on a robot and to patent a special device for this purpose. This was followed by a mixing head with a changeover device and, finally, a changeover module, with which it is possible to swivel from one nozzle to the other within a few seconds. Patent applications have been filed in various countries, some of which have already been granted. The team led by Alexander Berg and Ralf Moser developed the interchangeable piston, and Fredrick Su, as a sales representative, knows the customers already using it, such as the automotive supplier Trèves.

Sergi Salart, South Europe Industrialization Manager, emphasised:

“The efficiency of our spraying process in Treroc / Morocco is mainly based on the nozzle changing system. We are so satisfied that we will soon introduce it at our Romania plant, too.”

What are the advantages of the new technology?

Compared to the conventional method of operating two robots with one nozzle each? It saves considerable investment costs. However, it is also common in the industry to use either the flat or round jet nozzle for the entire process – which also has disadvantages. A look at the discharge quantities and geometries is helpful here. A round jet nozzle has a throughput of around 50 grams/second, and the maximum spray width is 120 millimetres. Atomisation is carried out with air, the spray pattern is conical, and the polyurethane track on the flat glass fibre mat is clearly rounded. On the other hand, the flat spray nozzle delivers up to 130 grams / second and works without air support. The mat has a rectangular shape.

The flat jet nozzle is ideal for those who want to get a large area quickly. However, it will use more PUR than necessary, as superfluous areas are also covered when reinforcing the edges. On the other hand, the round jet nozzle requires considerably more time, but it can precisely target the edge areas for reinforcement.

Switching between flat and round is the ideal solution – but it has to be fast. The nozzle change module fulfils this requirement. For example, if you start with the flat jet nozzle and thoroughly spray the loading floor, the discharge channel is cleaned in around three seconds using compressed air. The change to the round nozzle is carried out hydraulically by pushing the second channel geometry into position. This only takes about 100 milliseconds, and the process continues. The mixing head is equipped with spring-loaded nozzles or nozzles with various equipment to handle the variable material quantities—the latter works with an air cushion located in a gas chamber behind the nozzle. In the event of fluctuations in the component throughput, various nozzles balance the pressure better and achieve optimum process parameters with different discharge rates.

The cycle time of a component includes the spraying time, the handling, the pressing of the components and finally, the PUR reaction time. The amount saved when applying PUR can be calculated and depends on the respective application. For a component measuring 2200 x 1200 millimetres, the spraying time is reduced by up to 30 per cent.

Anyone planning a new system for PUR processing would be well advised to invest in changeover technology right away, as Sergi Salart from Trèves emphasises:

“We are delighted with how reliable, low-failure and low-maintenance our PUR systems from KraussMaffei are – and are therefore planning more.”

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email