Solinatra Unveils Expansion of R&D Centre Complete with Two All-Electric PX Moulding Machines from KraussMaffei UK

|

Getting your Trinity Audio player ready...

|

Solinatra manufactures truly sustainable alternatives to single-use plastics, using innovative biomaterials that are 100% natural and plant-based. As part of the company’s recent expansion, it unveiled new facilities at its research and development centre in Norwich, complete with all-electric PX injection moulding machines all-electric PX injection moulding machines from KraussMaffei UK.

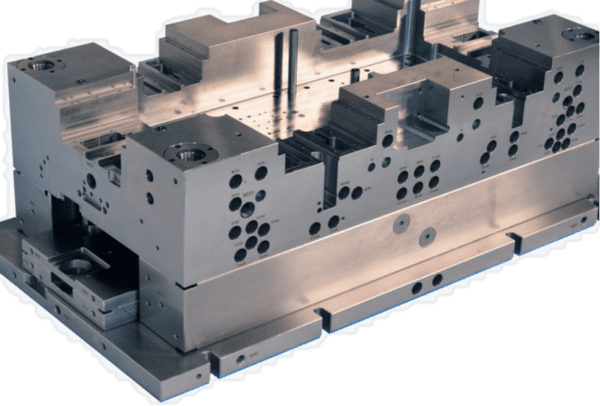

In an innovative move towards advancing sustainable manufacturing, Solinatra, a pioneer in biobased materials, has collaborated with KraussMaffei UK to enhance its in-house production capabilities. This partnership marks a significant step forward with the acquisition of two state-of-the-art 120-tonne PX all-electric injection moulding machines, installed at Solinatra’s R&D centre in Norfolk, England.

Solinatra, renowned for its innovative approach to replacing single-use plastics with 100% natural, plant-based materials, has taken this initiative to bolster its research and development efforts. The PX injection moulding machines are integral to Solinatra’s mission of advancing biomaterials that combine the beneficial properties of plastics without the environmental downsides, and will form the basis of Solinatra’s newly expanded R&D centre, providing an additional building for customer support and development.

Enhancing Capabilities and Supporting Sustainability

The collaboration between KraussMaffei UK and Solinatra is built on a foundation of shared values and a mutual commitment to technological excellence. Stephen Rundle, Solinatra’s Chief Operations Officer, highlighted his longstanding relationship with KraussMaffei UK and their technology’s significant role in Solinatra’s product development and customer support strategy.

“Solinatra is at the forefront of creating truly sustainable alternatives to single-use plastic, leveraging renewable resources to craft biomaterials that meet our high standards of functionality and environmental responsibility. The addition of KraussMaffei’s PX injection moulding machines empowers us to further our research, and support our customers much more effectively, ensuring a seamless transition to bio-based materials in their production lines,” said Rundle.

When asked why Solinatra opted for KraussMaffei’s PX machines specifically, Stephen added “The KraussMaffei PX moulding machines are very capable, fully electric injection moulding machines that enable us to continue to prove our materials on-site. The biggest benefit of going all-electric for our materials, particularly, is because of the enhanced control you get over the injection process. You get much more precise control with electric machines compared to hydraulic for example.”

Furthermore, the all-electric nature of the PX machines aligns with Solinatra’s commitment to environmental sustainability, offering a cleaner, more energy-efficient manufacturing process.

“Also with its lower energy consumption, there is an environmental case for the PX machines too. We’re an environmentally conscious company that must walk the walk and follow through with our sustainable goals, these machines enable just that.”

Solinatra Customer Centre is Now Open

The acquisition of the PX injection moulding machines is more than a technological upgrade for Solinatra; it represents a significant expansion of their capabilities and services. These state-of-the-art machines enable Solinatra to enhance its in-house material testing and trialling processes.

The new additional facilities at the R&D centre allows fully functional customer trials to be carried out at Solinatra’s Norwich site, enabling customers to use their existing tools to recreate plastic products from a more sustainable material alternative, all under Solinatra’s expert guidance.

Stephen Rundle also stressed the importance of working closely with his customers to ensure favourable outcomes when changing to alternative materials.

“This is a customer-driven project as we continue to grow and develop in the UK. We felt our customers had a greater need for support and we needed to satisfy that need. Lots of material companies will send you a bag of material and say, ‘Get on with it!’ We come from a very different angle. Biomaterials and plant-based materials, in our case 100% natural materials, can behave differently to fossil-based plastics and they need to be treated slightly differently. So, we try to educate our customers and work closely with them to ensure the best results for their application.

“Our machinery acquisition and the opening of a dedicated R&D area to support these customer trials will be a huge step forward in improving our customer experience and for trialling new applications of our material range.”

For Solinatra’s customers, this advancement means greater support in adopting sustainable materials in their production lines. The new machinery facilitates the development of custom bio-based solutions tailored to specific product applications, allowing for pre-production runs and in-depth material testing to be carried out at the Solinatra site, before moving into full production at the customer’s premises.

This customer-centric approach, supported by advanced technology, positions Solinatra as a partner of choice for companies seeking to transition to more sustainable manufacturing practices without compromising on quality or performance.

Future Outlook and Continued Collaboration

Looking ahead, Solinatra and KraussMaffei are set to expand their collaboration, exploring new avenues in biomaterials production, including new materials for extrusion and thermoforming technologies set to launch this year.

Stephen summarised “We’re delighted to be working closely with KraussMaffei UK, both on this project and looking into the future. As well as providing very capable, easy-to-operate machinery that suits our application and company ethos, the technical support from the UK team has been second to none.

“I often say that every process can have its issues, but it is when these issues appear that you can truly judge the quality of your supplier. The KraussMaffei UK team have consistently shown themselves to be reliable, approachable and technically capable. Michael Rudd and Simon Roberts have been particularly crucial and worked closely with us over recent years; their experience has been invaluable. “

This ongoing partnership promises to bring forth advancements in sustainable manufacturing practices, offering viable, eco-friendly solutions to a global market increasingly focused on reducing its environmental impact.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email