There are many major benefits for automating within the medical device industry, including speed, cleanliness, but more importantly, having control of the process. In this highly regulated sector, which factors will influence costs, and how can these costs be minimised? SP Automation & Robotics explain in this blog article.

Cleanrooms are an essential part of a safe medical manufacturing process. But how clean can a cleanroom be? The environmental Read More

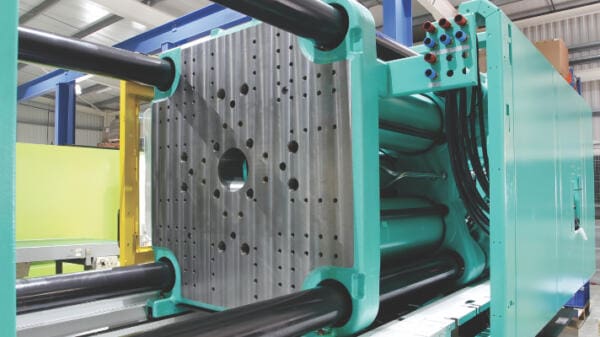

Clamp force is one of the most overlooked portions of the injection moulding process. How many times have you walked Read More

Ripples from the BBC’s ‘War on Plastic‘ series continue to be felt within the industry, as public opinion of Read More

As a manufacturing or engineering business, what factors should you be taking into consideration when selecting a recruitment partner? Willcox Read More

When assessing plastic as a substitute for metal, there are many factors to take into consideration. Not all are strictly Read More

Non-compliance with regulations can have the most devastating impact on lead times of medical device packaging and labelling. In this Read More

Putting a sensor anywhere in a tool can give you some form of data, but it may not be value-added. Read More

As manufacturers face the pressure of delivery deadlines, planned maintenance usually drops down their priority list. In this informative blog, Read More

Since its introduction in the 1970s (yes, ’70s!) Moldflow software has revolutionised the design of plastic products using scientific principles. Read More

Recent Posts

- Additive Manufacturing 181

- Auxiliary Equipment 401

- Case Studies 71

- Digitalisation & Industry 4.0 56

- Industry Updates & Events 424

- Material Handling & Temperature Control 246

- Plastic Materials & Additives 733

- Plastic Processing Machinery 913

- Plastic Processors 588

- Plastic Recycling & Sustainability 328

- PlastikCity on Tour 33

- PlastikMedia HotSeat 109

- Robots & Automation 254

- Service Providers 600

- Toolmakers & Mould Components 233