Big Savings and Solutions from Wittmann at K 2025

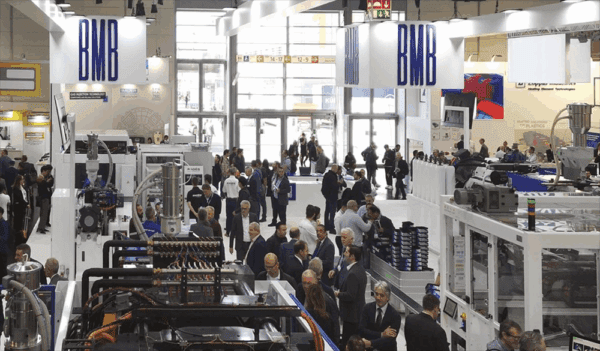

For the first time, K 2025 will see Wittmann exhibit all of its injection moulding solutions – featuring machines, automation, ancillaries, recycling, industry 4.0 technology hardware and software – on one single stand – the company’s largest exhibition space yet.

And there is a lot to exhibit: Wittmann’s perennial “one-stop-shop” message – its features and benefits – will be amply illustrated and underscored by the performance of a variety of production cells within the Düsseldorf Messe– all presented under the banner – “It’s All WITTMANN”.

The benefits of buying an injection moulding system – as opposed to a collection of separates – will therefore be made clear as day, and the traditional Wittmann themes of customer-led design and class-leading energy efficiency will also be a key visitor draw.

Wittmann’s machine building style and innovation will also jump out, namely: a very compact build in 3 dimensions, class-leading energy efficiency and process control, together with the largest possible platen size – relative to locking force – in order to optimise machine value and technology.

New Wittmann products to be launched at K 2025 include the company’s first MacroPower, which will feature a one-piece machine body: The new MacroPower 500/3400 presents as even more compact than usual, allowing easier transportation and commissioning at the customer. In addition, a pivotal injection unit – accessible from front and rear – will make screw changes much easier.

This new one-piece MacroPower is fitted with Wittmann’s Unilog B8X control system. This includes several control system components developed in-house. These features make it possible to reach a higher internal clock frequency, creating shorter response times to sensor signals and resulting in a higher reproducibility of parts.

K 2025 also sees the launch of Wittmann’s new EcoPrimus – a grafting of the cost-effective Primus concept onto the company’s leading energy saving IMM – the EcoPower.

As an all-electric machine model, the machine savings lie primarily in the use of electric energy: Wittmann positions the EcoPrimus as the perfect answer to the current demands of today’s market – dominated by applications requiring only a small range of options. This machine comes with the latest-generation control system from the WITTMANN Group, i.e. Unilog B8X. The EcoPrimus has been released for sale from the K show onwards in size 100, that is, with 1,000 kN clamping force.

Dan Williams, Wittmann UK Joint MD, says that ‘come October, our UK and Irish customers can look forward to a Wittmann K show experience that offers better than ever outcomes.’

Dan adds that ‘it is clear that the global economy is going through turbulent times. Our K stand organisation and customer support is therefore designed to help the customer with immediate value. We have arranged this value across four key metrics: saving time, saving energy, saving material and saving space.

K Show visitors will find that every one of our work cells has been assigned to deliver at least one of these metrics – the numerical values of which can be made clear from simply pressing a button on the exhibit.’

Wittman Joint MD, Tracy Cadman says that ‘now – more than ever – customers need proven value; not only in terms of plastics technology and efficiency but also in terms of service; where one phone call can tackle any issue involving any part of an injection moulding production cell.

She adds that ‘here in the UK and Ireland we are very fortunate to be able to supply all moulder needs via our one-stop-shop. We also benefit from the continuous technical innovation that the Wittmann Group provides to us year-on- year.’

At the K Show, Wittmann will exhibit in Hall 15 on Booth 22. The company will also participate in The Power of Plastics Forum, outdoor area E06, and on a partner company’s booth as well.

Read more from Wittmann Battenfeld here.

Wittmann Battenfeld UK

01933 275777

Website

Email