New Space Saving, Fully Adjustable Vertical Co-Extruder

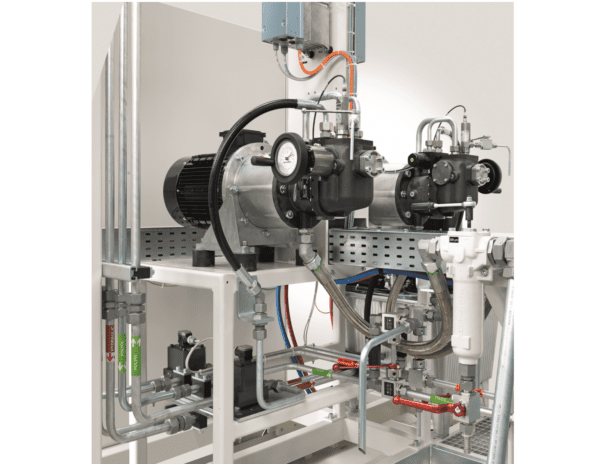

Extrusion machinery manufacturer Boston Matthews is pleased to announce a new space-saving Vertical Co-Extruder (Jockey) and main Extruder production set-up.

The new extruders are designed using one common base, thereby reducing the usual footprint to a minimum and saving valuable production space.

The unit shown comprises of a 75mm main single-screw extruder with a 30mm Vertical Co-Extruder, with the company offering a range of extruder sizes/outputs to meet the customer’s specific requirements. This also includes options for processing Fluorocarbons and high-temperature polymers such as PEEK.

Complete Movement For Faster & Easier Alignment:

The Vertical Extruder has complete movement – including up & down, forward & back; and a complete 270° swivel. This virtually eliminates all alignment and reduces it to just fine adjustment. The precision fine adjustment will help to simplify and reduce set-up time whilst minimising the risk of damage to the tooling during the process.

Both Extruders are controlled by one central control system using the Boston Matthews developed SMART Control System. This colour touchscreen PLC control provides total control, recipe storage, alarms, trending, network connectivity, management set security levels, production data export and production monitoring safety controls.

Energy-Efficient Precision Production:

AC, direct-drive technology provides precision screw speed holding for the highest quality melt and output performance while ensuring maximum energy efficiency is obtained. Direct-Drive also greatly reduces operational noise, dust and routine maintenance.

Any routine maintenance has been designed so that the operator can carry it out without the need for calling on specialised maintenance personnel.

Read more news from Boston Matthews here.

Boston Matthews

+44(0) 1905 763100

Website

Email