UNTHA UK | Shining the Spotlight on ‘Trickier’ Plastics

Plastic shredding has long been a popular topic, and with mounting public attention surrounding single-use plastics and all-things-environment, this trend looks unlikely to change any time soon. But while plastic processing innovations and practices have advanced in recent years, what about when we delve into the more complex side of plastics? Marcus Brew, managing director of UNTHA UK, shares his thoughts on this topic, particularly about the persistent organic pollutants – POPs – found in some Waste Electrical and Electronic Equipment (WEEE)…

Plastic recycling in the UK

In 2021, The Waste and Resources Action Programme (WRAP) revealed that circa 1.2Mt of the UK’s plastic packaging was recycled in 2020 – four times higher than in the early 2000s.

And while this upward trend is positive, there is no denying that there is still work to be done. This is a point that is further compounded by the continued attention given to plastic recycling in governmental policies and environmental legislation.

From the implementation of deposit return schemes (DRS) to the introduction of the plastic packaging tax, there are many initiatives that have been launched to help combat avoidable plastic waste and foster a circular economy mindset.

But attention must also be given to plastics which can be trickier to process.

And with it being estimated that the average plastics content in WEEE stands at approximately 30%, this is one of those more complex areas which merits a closer look.

Tackling the more troublesome plastics

POPs – also sometimes known as ‘forever chemicals’ – are organic chemical substances with toxic properties, and they can be found in many waste streams, including some WEEE.

Due to this substance’s specific physical and chemical properties, POPs can have a long-lasting impact on environmental and human health if not managed correctly during the waste disposal process.

Government guidance states that operators must ensure waste containing POPs is disposed of at an authorised site or “irreversibly transformed” using one of the permitted compliant methods.

The Environment Agency’s updated guidance on POPs has caused ripples throughout the industry, but as is often the case, innovation is already driving change.

How one plastic recycler is leading the way

Plastic recycler, 3R Technology, is a shining example of what’s possible in the ‘complex plastics’ space – using shredding technology to help solve its WEEE plastic processing challenge.

With more than 20 years of experience – particularly in the Belgian market – 3R Technology’s attention recently turned to the UK and the WEEE plastic processing challenge. The ambitious scrap handler has invested in new technology to bolster its UK operations.

Approximately 2,000 tonnes of shredded small domestic appliance (SDA) plastics are being handled by the team every month at their 5000m² warehouses in Preston.

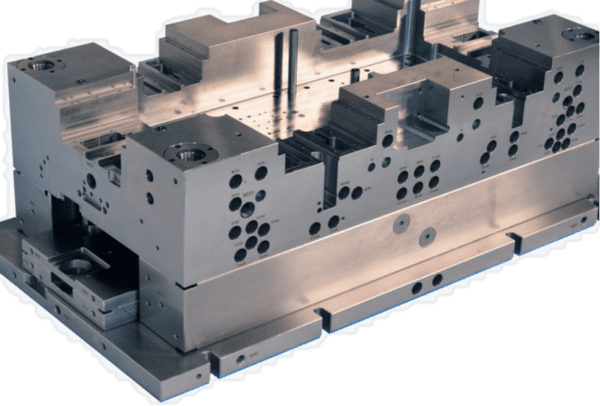

Two UNTHA shredders lie at the heart of the state-of-the-art plant. A single shaft UNTHA LRK plastic shredder processes PS fridge plastics, and a four post-UNTHA RS40 screen achieves a refined 30mm fraction after processing the SDA mix. Particle homogeneity is ensured by both machines.

The post-shredded plastic is transported via a conveyor belt to the washing line with a floating tank to be cleaned and dried. ABS/PS and PP/PE material are then run through an electrostatic separator to create pure, high-value ABS and PS flakes for remanufacturing.

But having rigorously tested the state-of-the-art processing line, 3R Technology is on the hunt for more material heading into next year and beyond. The site is capable of recycling various plastics, including flat-screen TV cases, computer monitor housings, and computer-based peripherals.

The goal is to reach an annual processing milestone of over 5,000 tonnes this year, with plans to open two other plants in the South of England and Scotland shortly.

At the time of the installation, 3R Technology’s founder and CEO, Yu Lin Wang, said: “The UK’s WEEE recycling capabilities are continuously improving. However, the focus is usually the processing of metallic content. We’re therefore partnering with WEEE and scrap metal handlers to tackle the 50% mixed plastic that typically remains once redundant appliances have been shredded. This still has a significant resource value, which often isn’t realised in the UK.”

This is not 3R Technology’s first UNTHA investment.

“We use UNTHA at our Dutch plant too,” elaborated Mr. Wang. “So, when it came to selecting the processing machinery for our UK facility – equipment that is easy to use, simple to maintain, and has an impressive capacity – we knew where to go.

“UNTHA shredders make the job of our downstream technology so much easier – we’re able to segregate a further 3-5% clean metal from the floating table, which boosts our revenue stream. Our site is attracting much attention, particularly on social media, so we’ll continue to be very vocal regarding what we can do. We even encourage people to come and take a look!”

3R Technology also has WEEE recycling facilities in Serbia and The Netherlands.

What’s next for plastic recycling?

As in any environmental sector, operators demand greater throughputs, particle precision, and material flexibility while driving down energy consumption and maintenance to reap environmental and financial gain. And rightly so! This is precisely what technological innovation should achieve – more, with less.

Things are no different when it comes to shredding plastics. But to step it up a gear and address the more ‘technical’ areas across the plastic spectrum, innovation and industry-wide collaboration have to take center stage.

Read more about UNTHA UK here.

UNTHA

0330 056 4455

Website

Email